plastic mold

-

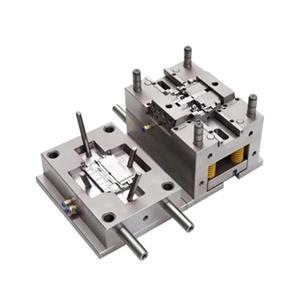

Plastic Electronics Mold For Interphone Injection Case

Professional experience in one-stop solution on tooling and production; Satisfy the precision mold requirement in wide rage industry; Can do from mold design to manufacturing. 1. We have our own tooling shop, equipped with advanced machines for plastic injection mould and the plastic injection products. 2. We also have their own injection shop, to run the mold test & mass production for customers. 3. We have more than 800 mould making experience for plastic injection mould and more than 15years experience for plastic injection. 4. We have 20 precision production equipment which reach the international advanced level and the experienced technician. 5. ISO 9001 Certified for all of our plastic injection mould and plastic injection products and our factory;

Plastic Electronics Mold Electronics Mold Mold for Interphone Injection Case Mold for Injection CaseEmail Details -

Mini Elliptical Machine Molding

Customized mini elliptical machine, OEM/ODM appearance logo, one-stop plastic molding service.

Email Details -

Smart Home WIFI Shell Molding

Smart home WiFi is an innovative technology product that integrates wireless network connection, intelligent control, and appearance design to provide users with a convenient, efficient, and beautiful smart home experience. KCN Plastic Molding provides OEM and customized shell molding for many smart home brands. It uses ABS injection molding to increase the beauty and durability. The color and logo can be customized. If you have commercial needs, please contact us. One-stop solution and product molding.

Email Details -

Hot

Injection Mould Auto Connector Plastic Parts Mold

Professional experience in one-stop solution on tooling and production; Satisfy the precision mold requirement in wide rage industry; Can do from mold design to manufacturing. 1. Fast Quote: Based on 2D or 3D drawing, your sample, even your idea; 2. Mold Design 3. Tooling Maker: Injection mold, stamping die & die casting as well; 4. Plastic Injection Products Production 5. Secondary Process: Offer mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 6.After Service: For your smoothly running machine or product use.

Plastic Parts Mold Injection Mould Plastic Parts Mold Auto Plastic Parts Mold Injection Auto Plastic Parts MoldEmail Details -

Hot

Plastic Handle Mold

1.Start from part design analysis; 2.Mold design drawing and DFM report available so you can see how is the mold going to be before mold making; 3.If product is complex,moldflow report will be present as well; 4.In house mold making shop ensure you mold quality under well control; 5.Normally it takes 20-40 days to make mold,precise time depends on part design; 6.Can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

Email Details -

Fitness Equipment Plastic Mold For Injection Spare Part

We can offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement. 1. In the service of plastic injection, Ideal plastic is more than just an injection molder. 2. We provide solutions to manufacturing from start to finish. 3. Our expertise enables us to provide clients with superior product by providing the highest quality in design, development, and solutions for precision injection molding and related manufacturing. 4. We have over 15 years production experience. 5. Have more than 50 plastic injection mold machines, variety of precision mold produce equipment and spray printing equipment and more than 7500 square meters workshop.

Fitness Equipment Plastic Mold Plastic Mold for Spare Part Plastic Mold for Injection Spare Part Mold for Injection Spare PartEmail Details -

Custom Plastic Mold Plastic Products Injection Parts

1. We have excellent comprehensive performance and can replace traditional materials such as metal and ceramic in many special fields. 2. The high temperature resistance, self-lubrication, wear resistance and fatigue resistance of this plastic make it one of the most popular high-performance engineering plastics. 3. Application fields: we engineering plastics are widely used in electronics, household, fitness equipment, machinery, chemical industry, automobile and other high-tech industrial fields.

Plastic Mold Plastic Products Plastic Mold Injection Parts Custom Plastic Injection Plastic Products Injection PartsEmail Details -

Custom Mold Injection Plastic Mold

Advance Pre-sale service 1. Your drawing will be checked carefully or do the design for you by our professional and experienced engineer team; 2. Most of the materials or colors as your requirement. 3. Good Quality, Factory Price ,Quick Response and Reliable Service will offer you. Advance after you choose: 1. Design the mold drawing and provide DFM report. 2. Update the videos and pictures of each process of your order to check the quality. 3. Offer free samples for your check and confirm. Advance after-sale service 1. We are very glad that customers give us some suggestions for price and products. 2. If you have any questions, please feel free to contact us by E-mail or Telephone.

Email Details -

Precision Custom Plastic Injection Mould

1). Quickly response and complete understanding 2). The most competitive and reasonalbe price 3). Short delivery time and prompt delivery 4). Well and High Quality Control 5). Customer's Designs and Logos are welcome 6). Enough and advance machines and equipments.

Precision Custom Mold Precision Plastic Injection Mold Precision Custom Plastic Mold Precision Custom Plastic Injection MoldEmail Details