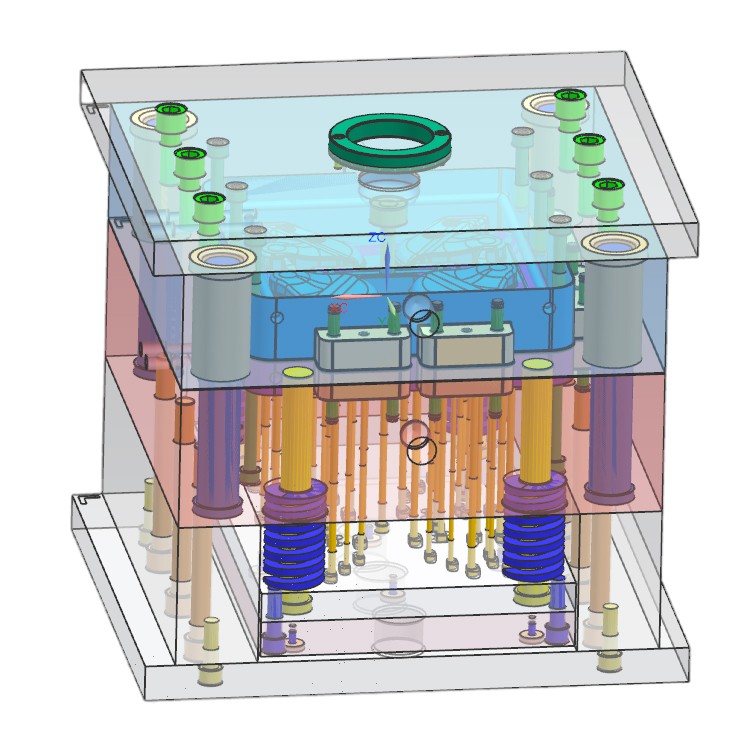

Plastic Industries Mould

-

Hot

Injection Plastic Parts Mould For Industrial

One-stop Service:

Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services;

Rich Experience:

High Quality, Competitive Price and Fast Delivery Time

more than 15years experience for plastic injection mould and plastic injection and developing capability;

Advance Equipment:

Imported sophisticated production and testing equipment with high stability.Injection Plastic Parts Mould Plastic Parts Mould for Industrial Injection Plastic Mould for IndustrialEmail Details -

Plastic Injection Moulding Industrial Mould

1.We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment.

Email Details

2.We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts.

4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts.

5. We have professional plastic injection mold tooling designer and plastic part producing line.

6. Plastic Injection Mould OEM & ODM Services -

Custom Plastic Injection Mold For Industrial Parts

1. High quality and factory price for plastic injection mould service;

2. Plastic injection mould design and making service and plastic injection service for over 30 countries; Provide high-volume injection molding solutions;

3. One-stop service from plastic injection mould making to plastic injection and assembly;Custom Plastic Injection Mold Injection Mold for Industrial Parts Plastic Injection Mold for Industrial PartsEmail Details -

Plastic Industrial Molding For Injection Parts

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment.

Email Details

2. Our workshop area is about 7500 square meters;

3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;

5. 3D Drawing service from plastic to plastic injection moulding tool design

6. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts. -

Plastic Parts Industrial Injection Mould

1. We have our own tooling shop, equipped with advanced machines for plastic injection mould and the plastic injection products.

Email Details

2. We also have their own injection shop, to run the mold test & mass production for customers.

3. We have more than 15years experience for plastic injection mould and plastic injection.

4. We have precision production equipment which reach the international advanced level and the experienced technician.

5. With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers. -

Universal Product Industrial Plastic Injection Mould

For Plastic Injection Mould:

Email Details

1. High quality raw material to ensure the high quality of the plastic injection mould;

2. Fast delivery, if the sample plastic injection mould, we can finish in 10days;

3. More than 800 mould making experience;

4. Can offer plastic injection making and injection plastic parts, silk screen print and spray paint one stop service.

For Plastic Injection Products:

1. Advance injection machine to ensure the quality;

2. Enough and many kinds of injection machines to ensure the quantity;

3. High productivity;