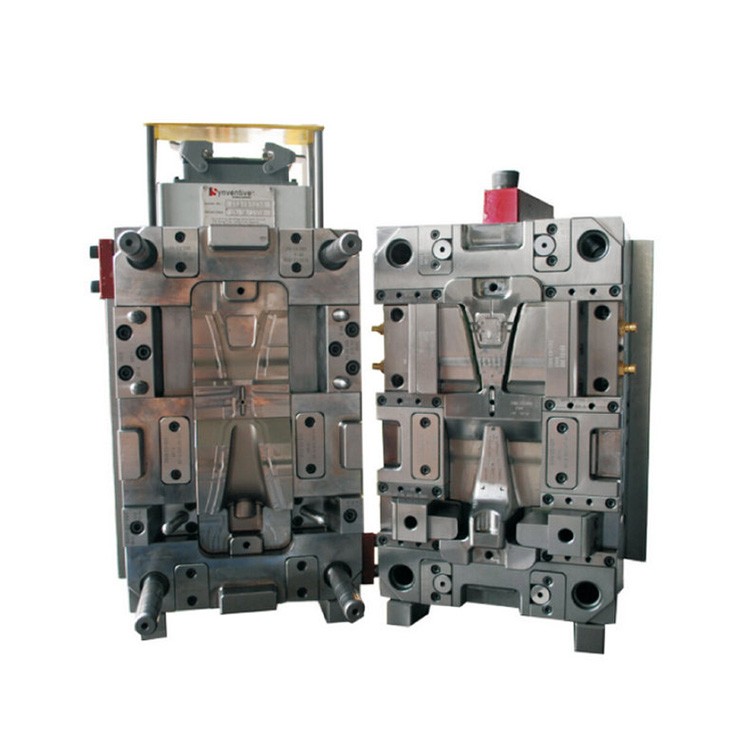

Plastic Electronics Mould

-

Customzied Electronics Plastic Injection Mould

For Plastic Injection Mould:

Email Details

1. High quality raw material to ensure the high quality of the plastic injection mould;

2. Fast delivery, if the sample plastic injection mould, we can finish in 10days;

3. More than 800 mould making experience;

For Plastic Injection Products:

With more than 15years experience and more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment to ensure the quality and quantity; -

Plastic Mould For Electronics Injection Parts

1. High quality and factory price for plastic injection mould service;

Email Details

2. Plastic injection mould design and making service and plastic injection service for over 30 countries;

3. Provide high-volume injection molding solutions;

4. One-stop service from plastic injection mould making to plastic injection and assembly;

5. With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

6. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; -

Hot

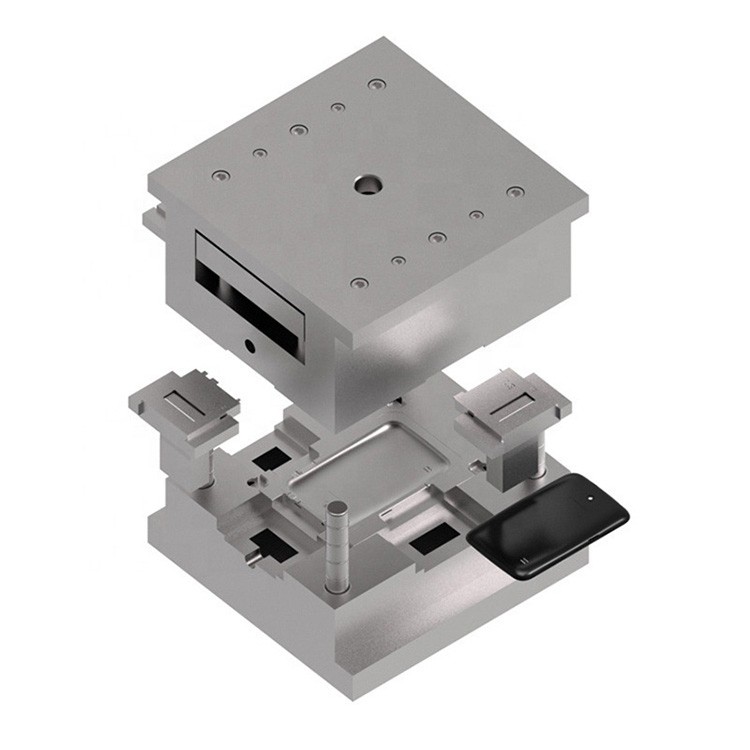

Plastic Mould For Mobile Phone Injection Cover

1. Fast Quote:

Email Details

Based on 2D or 3D drawing, your sample, even your idea;

2. Mold Design:

With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customer;

3. Tooling Maker:

Injection mold, stamping die & die casting as well and provide high-volume injection molding solutions;;

4. Plastic Injection Products Production:

Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

5. Secondary Process:

Provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

6. After Service:

For your smoothly running machine or product use. -

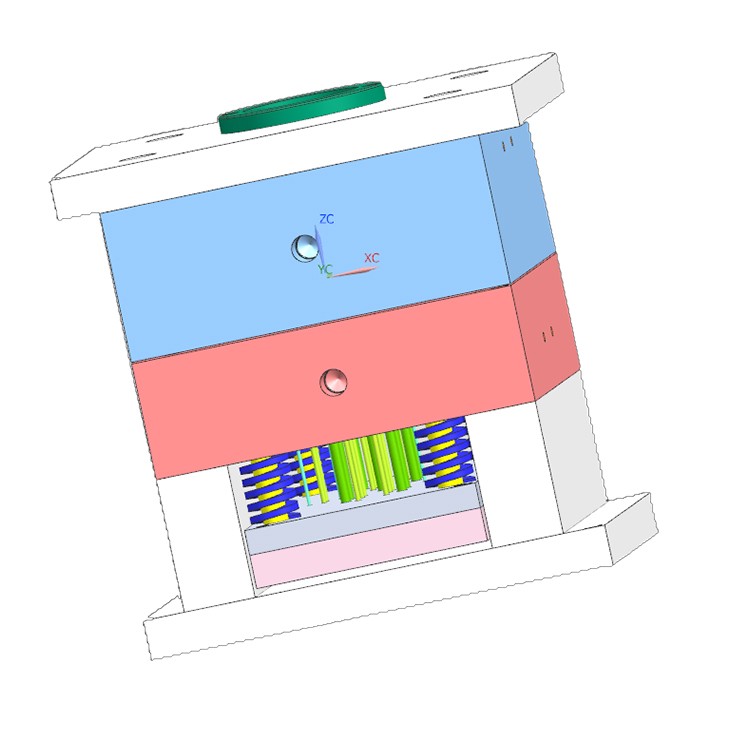

Plastic Injection Moulding Electronics Parts Mould

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment.

Email Details

2. Our workshop area is about 7500 square meters;

3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

4. 3D Drawing service from plastic to plastic injection moulding tool design

5. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts. -

Plastic Mould Electronics Parts Injection Mould

1. Have more 800 sets mold making experience;

2. Product engineering, development, consultation and the latest in manufacturing simulation software;

3. 2 After Sales Team help you solve any problem for plastic injection mold tooling and parts;

4. We have more than 10 professional plastic injection mold tooling designer;

5. Efficiency production, we can finish Push-Fit fitting mould of size 110mm in two cavity with in 45days.)Electronics Parts Injection Mould Plastic Electronics Parts Injection Mould Plastic Electronics Parts MouldEmail Details