Plastic Households Mould

-

Hot

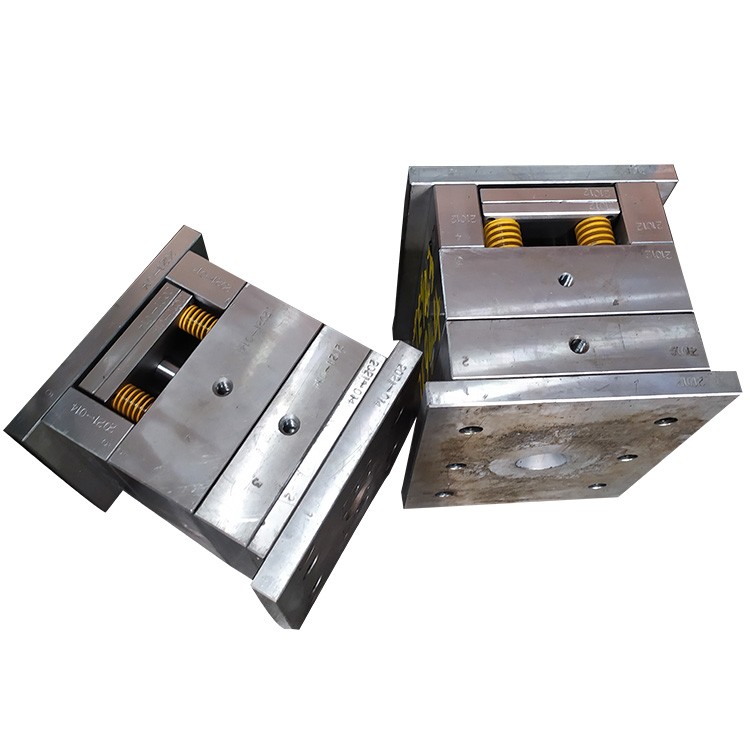

Precision Plastic Injection Households Mold

1. Good experience in mould making since the year of 2008.

Email Details

2. Machinery core pulling system save cost and increase production efficiency.

3. Perfect core pulling distance within 180mm.

4. Excellent R&D team.(We can offer you 3D mould design with all details within one day.)

5 .Efficiency production, we can finish Push-Fit fitting mould of size 110mm in two cavity with in 45days.)

6. Competitive price in save level of mould manufactuers. -

Homeware Injection Molding Plastic Mould

1) We are a professional OEM&ODM plastic injection mold manufacturer;

Email Details

2) We have a team with experienced engineers and quality control team as our strong backing;

3) High quality, competitive price, quick response;

4) Professional technical support;

5) Quick response;

6) A strict quality control process;

7) High-cost performance;

8) More than 15 years experience in plastic injection mold and plastic injection;

9) ISO/ERP system guarantee. -

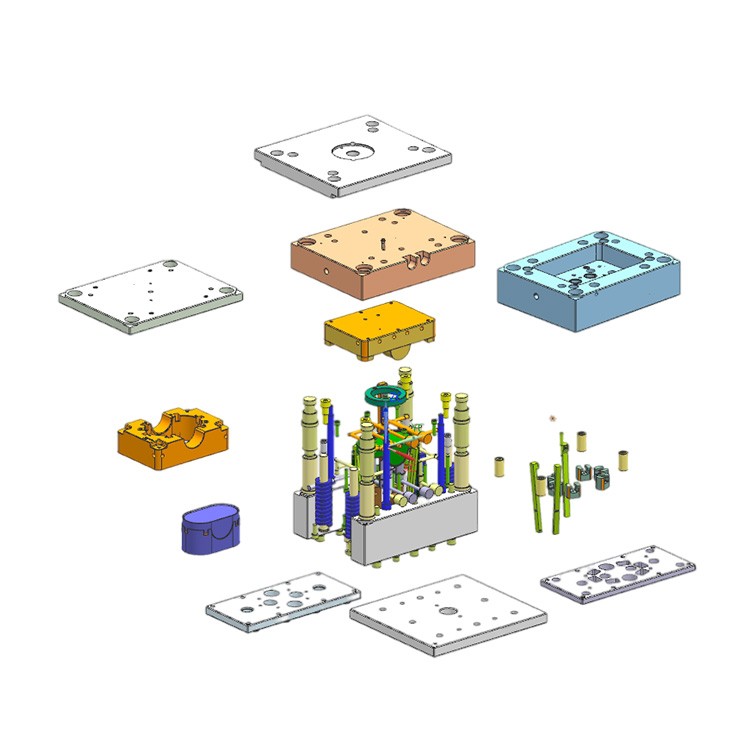

Household Molding For Plastic Injection Parts

For Plastic Injection Mould:

Email Details

1. Advance and enough equipment, high speed CNC, standard CNC, EDM, wire cutting, WEDM and grinder;

2. With more than 10 engineers can provide design service for plastic products and plastic injection mold, no matter 2D or 3D drawing;

3. With more than 800 sets plastic injection mold making experience since 2007;

4. Fast deliver conventional products, the lead time depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Molds are very simple and not big size, we can work out within 15 days. -

Precision Injection Plastic Households Mould

1. Have experience for more than 800 moulds

Email Details

2. 3D Drawing service from plastic product desgign to plastic injection moulding tool design

3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and plastic injection parts.

4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts.

5. We have more than 10 professional plastic injection mold tooling designer and advance plastic part producing line.

6. ISO 9001, ISO 14001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory -

Homeware Manufacturing Mould Plastic Mould Design

1.Provide one-stop service included plastic products and plastic injection mold design, mold making, injection production, screen printing, spray paint, assembly, packing and shipping;

Email Details

2. Enough and many kinds of equipment and machines for plastic mold and plastic injection to ensure provide one-stop service;

3. Our biggest injection machine is 950T, it can produce about and 600g plastic products and the biggest size is about 1*1*1 meter;

4. More than 800 sets mold making and more than 15 years experience in many industry, such as household, fitness equipment, bathroom and so on. -

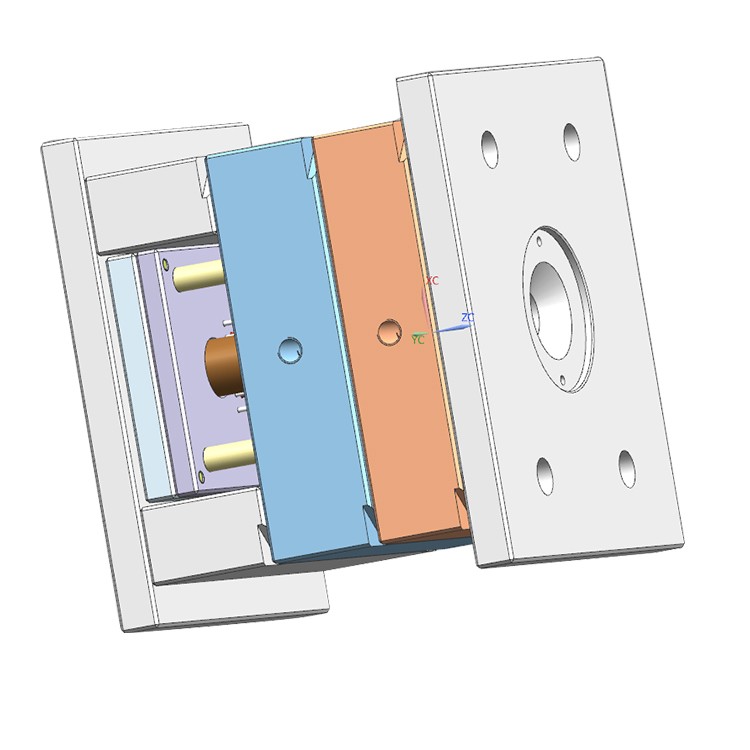

Injection Mould Plastic Products Molding For Homewares

1. Provide high quality custom plastic injection parts and plastic injection molds;

2. Plastic injection mold parts can be different material such as, ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET etc.;

3. Different plastic injection mold parts can pass different certification, such as UL test, V0 fire resistant test, FDA test, REACH test, SGS test and IP65;

4. Can also provide different surface treatment for plastic injection mold, such as Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding;

5. Beside plastic injection mold parts, we also provide printing, welding, assembly and packing service.Injection Mould Plastic Products Molding Plastic Products Molding for Homewares Molding for HomewaresEmail Details