Injection Mould Plastic Products Molding For Homewares

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. Provide high quality custom plastic injection parts and plastic injection molds;

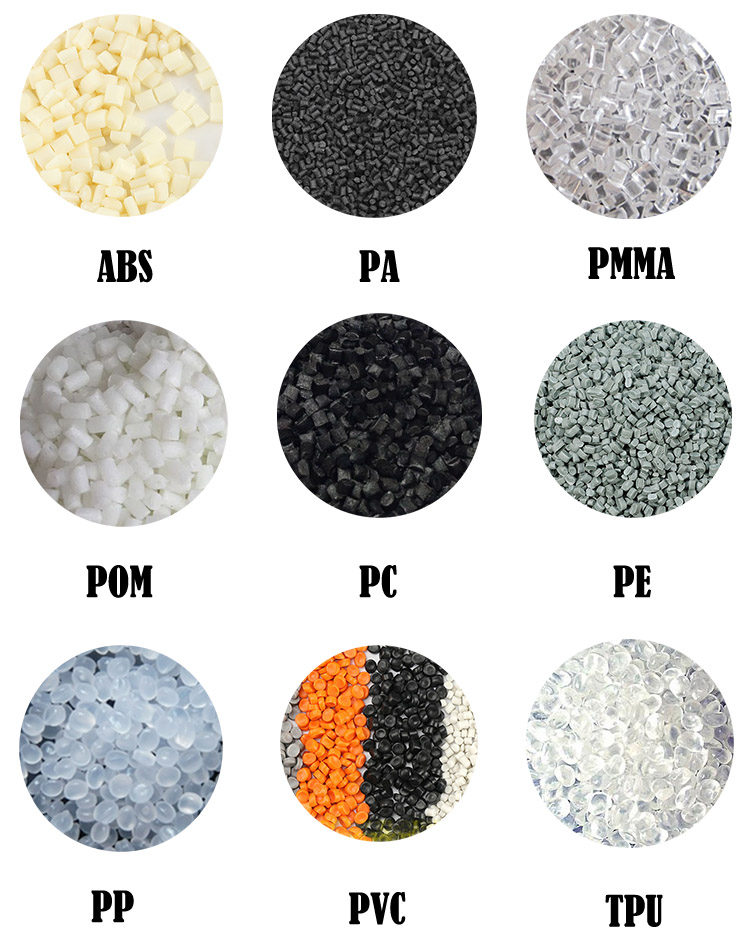

2. Plastic injection mold parts can be different material such as, ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET etc.;

3. Different plastic injection mold parts can pass different certification, such as UL test, V0 fire resistant test, FDA test, REACH test, SGS test and IP65;

4. Can also provide different surface treatment for plastic injection mold, such as Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding;

5. Beside plastic injection mold parts, we also provide printing, welding, assembly and packing service.

Injection Mould Plastic Products Molding for Homewares

Plastic Households Mould Specification:

Mould Base | DME, SD, LKM, HASCO and so on |

Mold Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Tolerance | High precision, tolerance can be within ±0.01mm |

Mold Life | 50K-1.5Million Shots |

Runner System | Hot runner/Cold runner or combined |

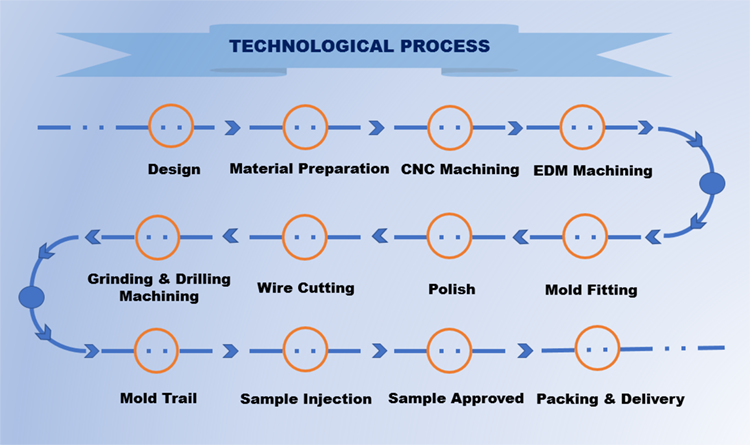

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 60 To 950ton plastic injection machines |

Plasitc Material | PA6, PA66, ASA, POM, PPS, ABS, ABS+GF, ABS/PC, POM(Derlin), PP, PE, PC, PMMA(Acrylic), PVC, PEI, PBT, PTF etc. |

Surface Treatmetn | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

Certificates | ISO 9001 |

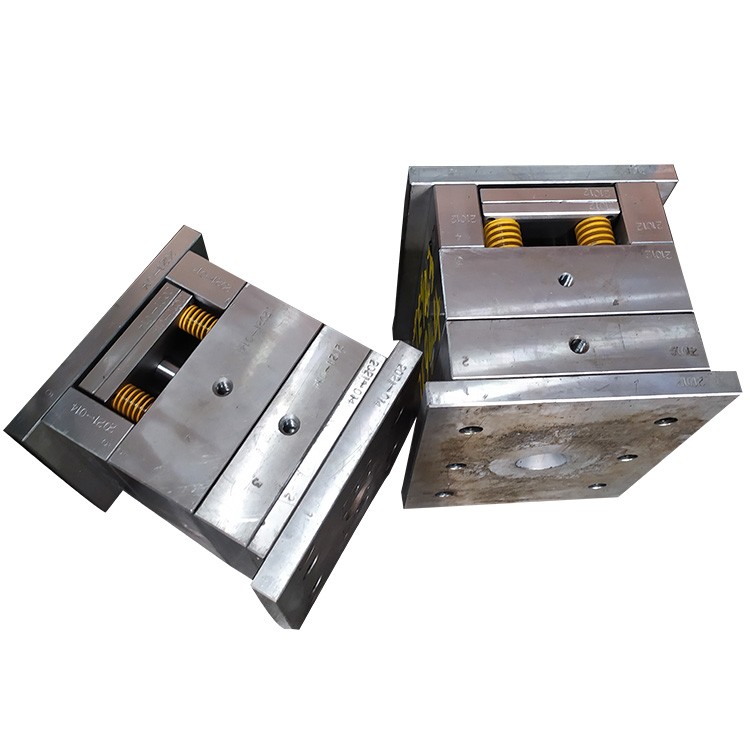

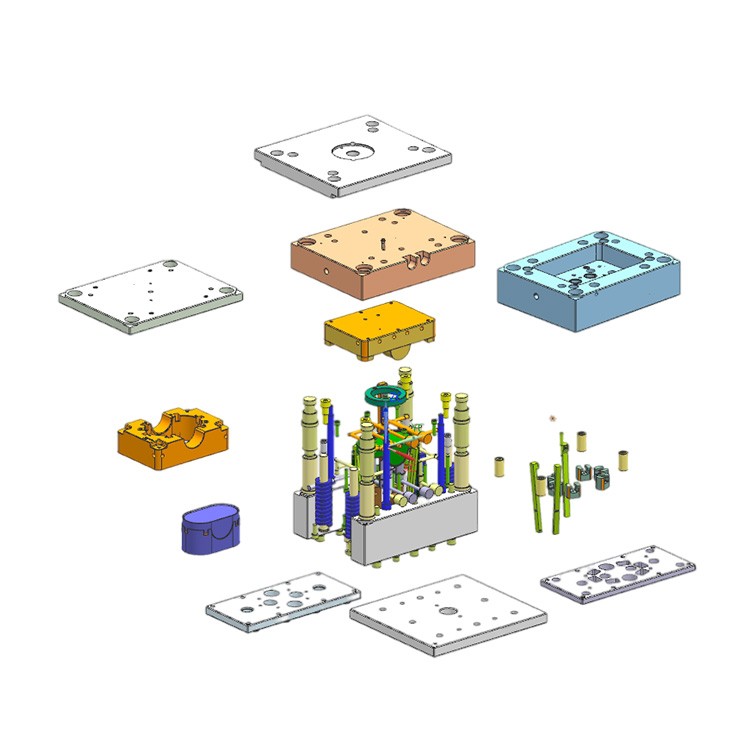

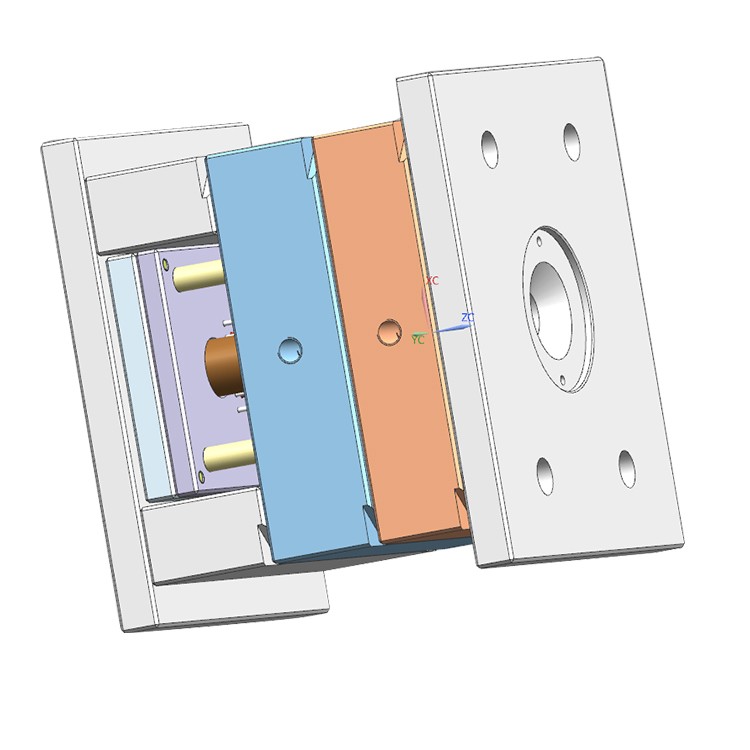

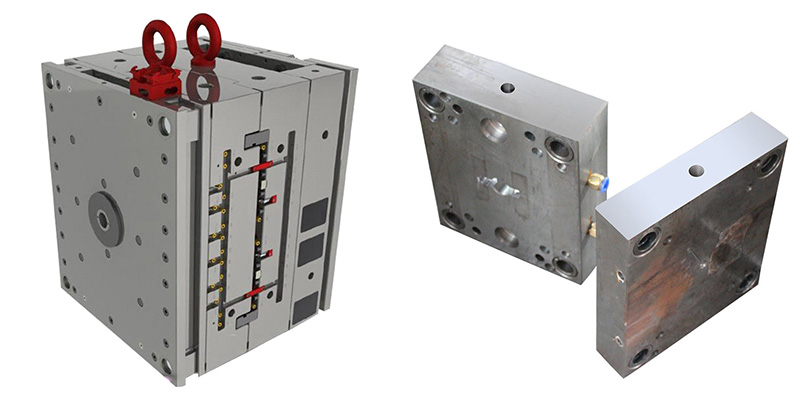

Plastic Households Mould Picture:

Plastic Raw Material:

The common material of the plastic parts as the following:

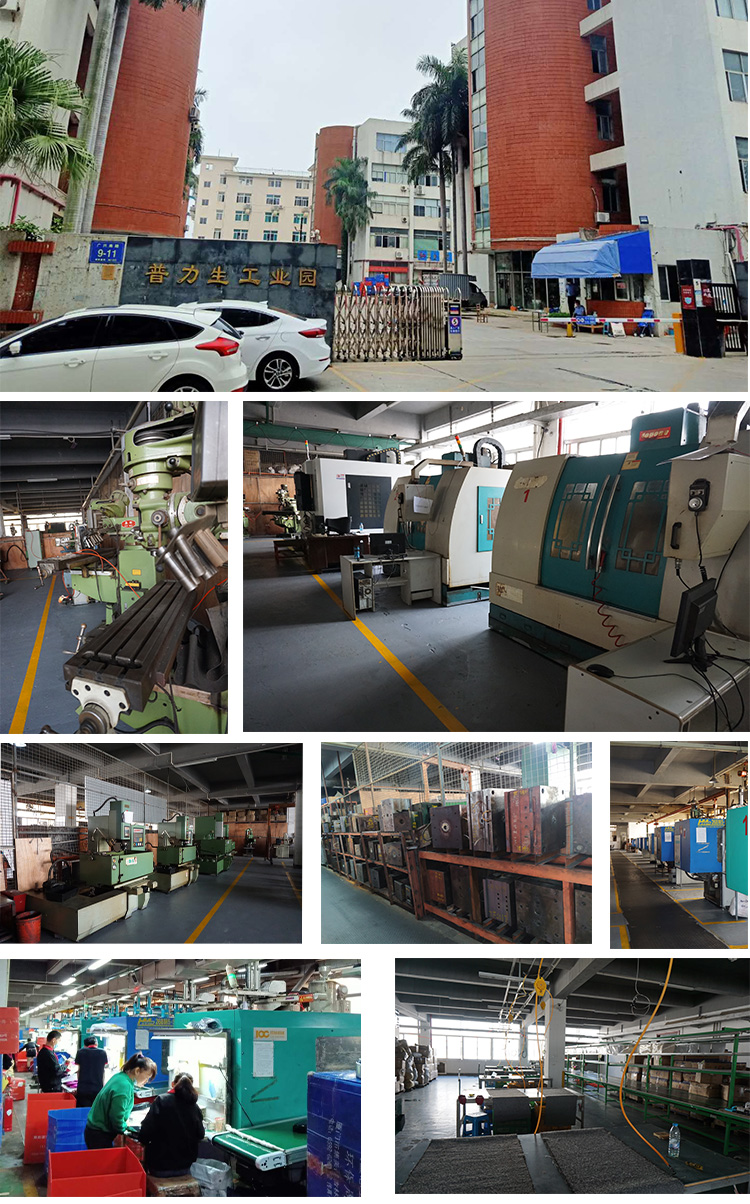

Plastic Households Mould Manufacturer Information:

We provide custom molds for customers all over the world, such as USA, UK, Canada, Indian, Europe, Asia and South America······.

We have been engaged in the mold industry since 2007. Our products involve medical, automotive, sports, hunting, electronics, containers, packaging and more.

Why so many customers choose to open mold?

Injection molds, which are usually made from steel or aluminum, carry a hefty cost. However, the cost per part is very economical if you need several thousands parts per year.

Injection molding is commonly used for making very high volume custom plastic parts.

Why choose our company?

Products design and moulds design are key-point for making good workable plastic injection moulds.

We have our own experienced and professional designing team. Meanwhile, we have various 2D&3D software for making both products design and moulds design which may ensure the design integrity, accuracy, reliability and quality.We can provide mold design, mold tooling, injection production, screen printing & spray pait one-stop service.

Product Qualification and Certificate:

Packaging and Shipping:

We will be coated one -layer anti-rist oil first, and then also will be covered thin filmson the mould, finally pack into non-fumigation wooden case.

Packaging Details:

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

4. Deliver out by sea or air.

Or according to customers' requirement.

FAQ:

Q: How can I get the quotation?

A: We will submit the quotation in 24 hours if getting detailed information during working days. If you can provide us the following information together with your inquiry, it will help us quotated fast and efficiently.

1) 3D Step of Files and 2D Drawings, if do not have the drawing, offer us the samples, or detail information about the sample such as, its size and weight;

2) Product material;

3) Product surface treatment

4) Quantity

5) Other demands or requirements, such as packing, labels,delivery,etc.

Q: How you do the quality control?

A:

1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out.

Q: How long is the lead-time for a plastic injection mold?

A: It all depends on the mold's size and complexity. Normally, the lead time is 25-45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.