Household Molding For Plastic Injection Parts

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

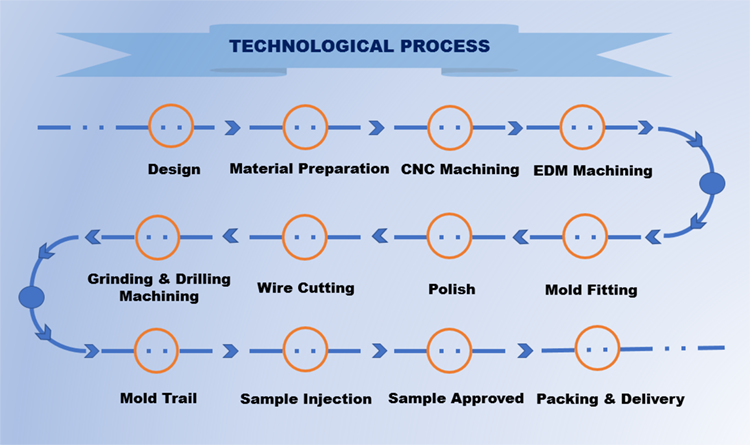

For Plastic Injection Mould:

1. Advance and enough equipment, high speed CNC, standard CNC, EDM, wire cutting, WEDM and grinder;

2. With more than 10 engineers can provide design service for plastic products and plastic injection mold, no matter 2D or 3D drawing;

3. With more than 800 sets plastic injection mold making experience since 2007;

4. Fast deliver conventional products, the lead time depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Molds are very simple and not big size, we can work out within 15 days.

Household Molding for Plastic Injection Parts

For Plastic Injection Products:

1. Advance and enough injection machines to ensure the quality and quantity, with

2. Enough and many kinds of injection machines to ensure the quantity; with more than 40 plastic injection machines from 60T to 950T. Can produce big size plastic parts.

3. Best service can provide one-stop service for plastic product customizing works from mold design, plastic mold making, plastic injection, silk screen print, paint, assembly work and packaging services.;

Plastic Households Mould Specification:

Product Name | Household Molding for Plastic Injection Parts |

Mold Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Mold Accuracy | +/-0.001mm |

Mold Life | 50K-1.5Million Shots |

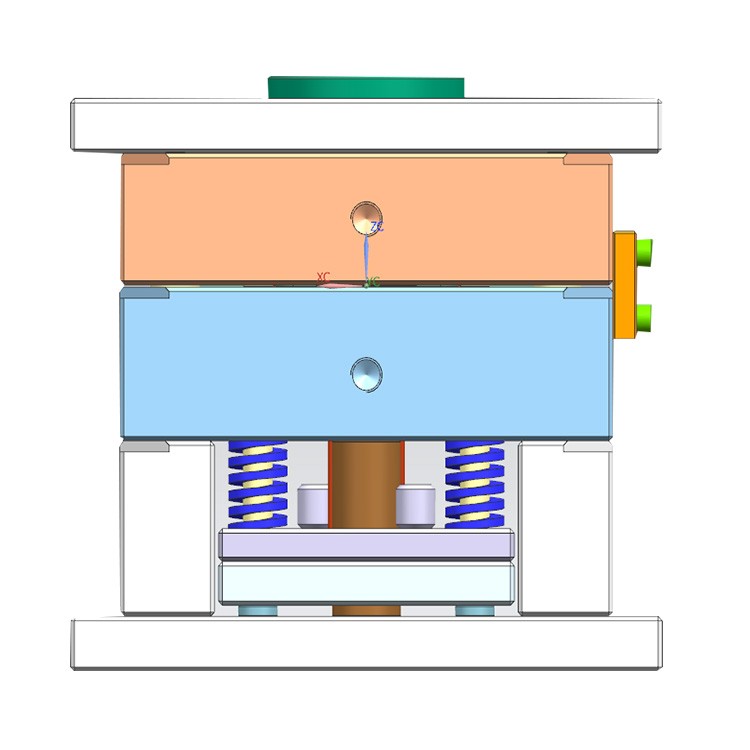

Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 60 TO 650ton plastic injection machines |

Plasitc Material | PA6, PA66, ASA, POM, PPS, ABS, ABS+GF, ABS/PC, POM(Derlin), PP, PE, PC, PMMA(Acrylic), PVC, PEI, PBT, PTF etc. |

Surface Finish | Texture(MT standard), High gloss polishing |

Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

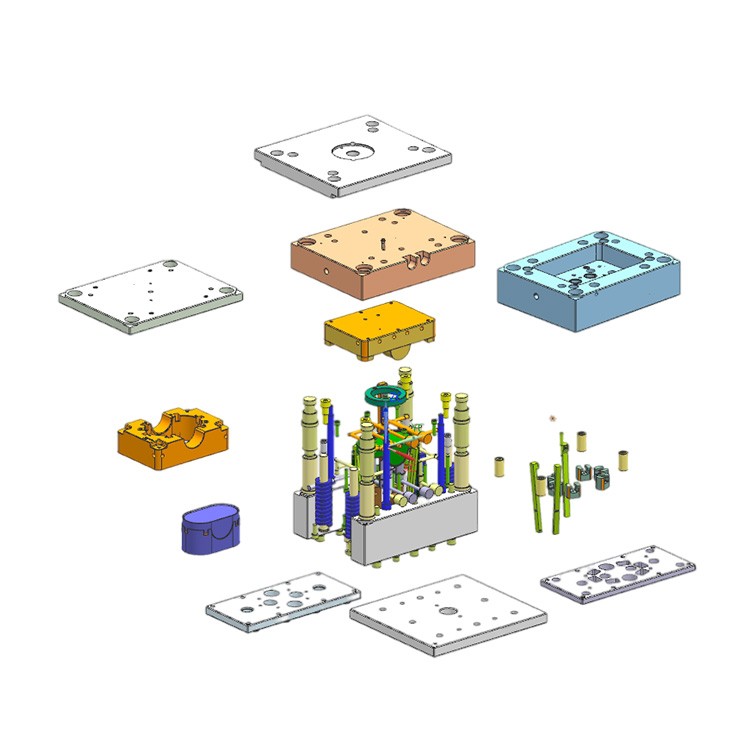

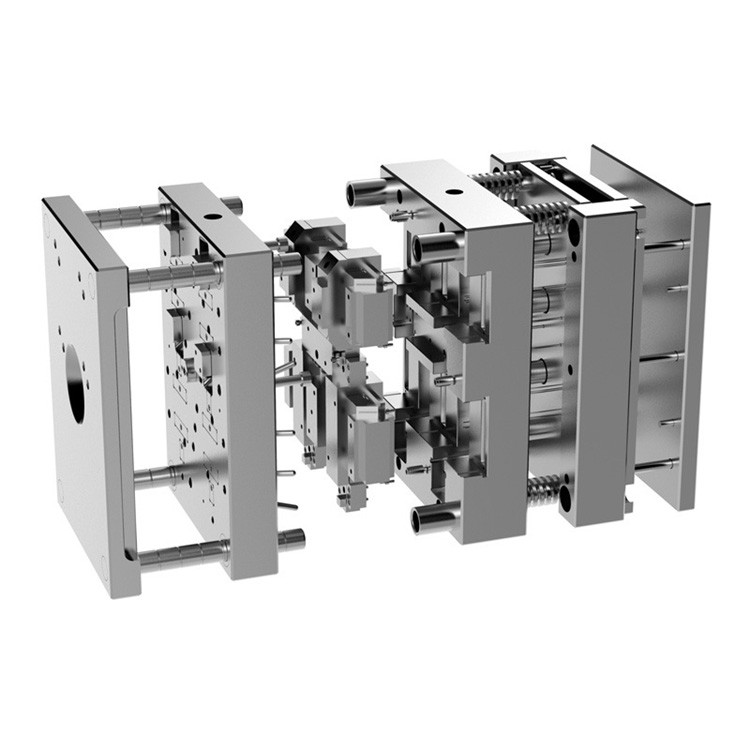

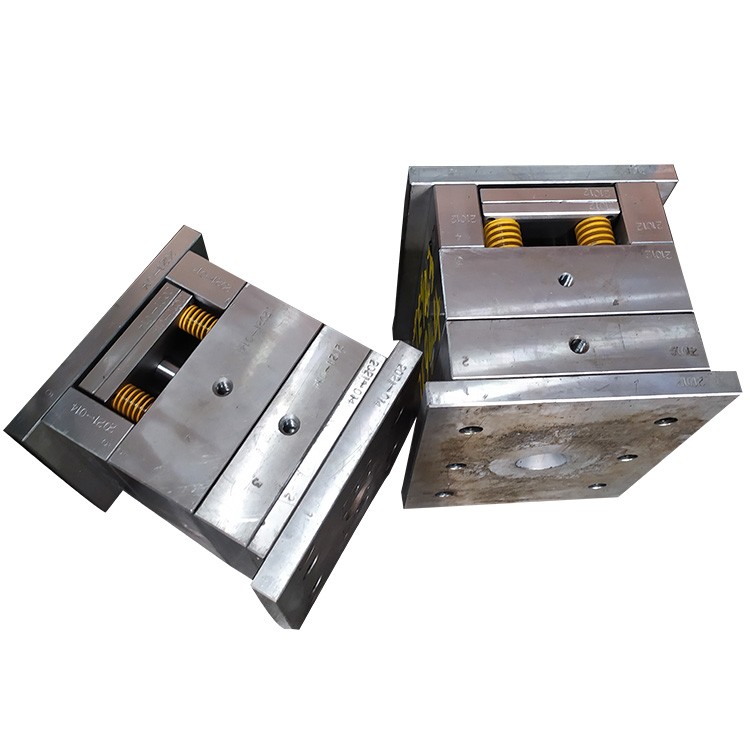

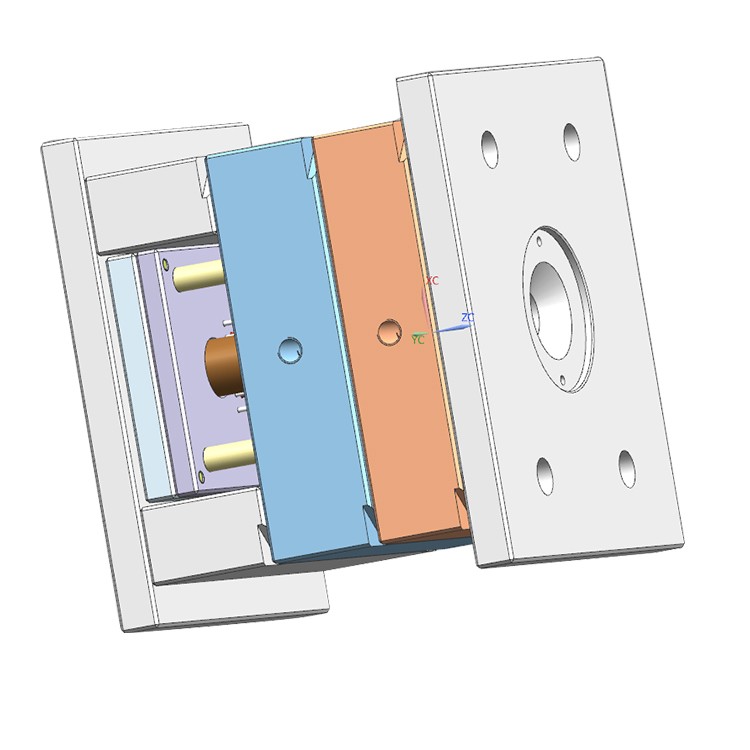

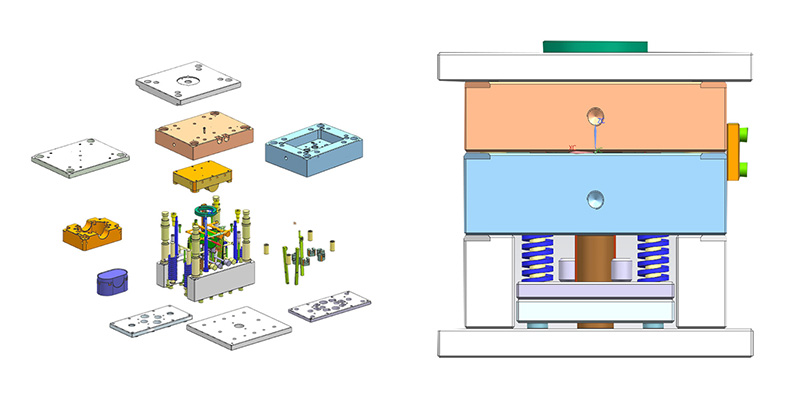

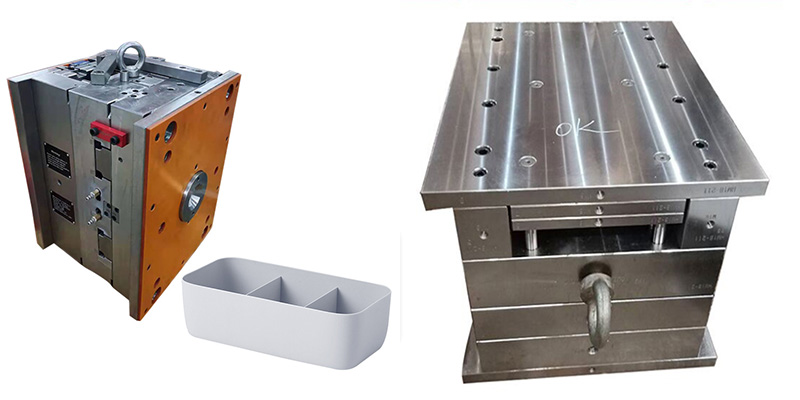

Plastic Households Mould Picture:

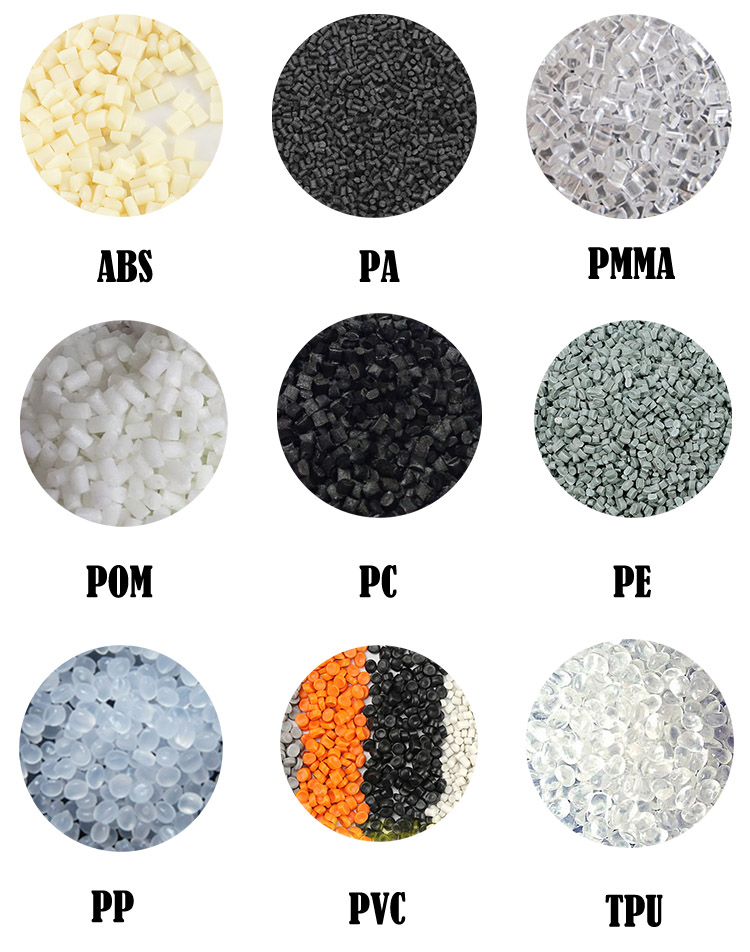

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, HIPS, PMMA, PC, PA6, PA66, PVC, PP, PE, TPE, TPU, TPR PBT, POM, PPS, PC, PPE, PPO, etc.

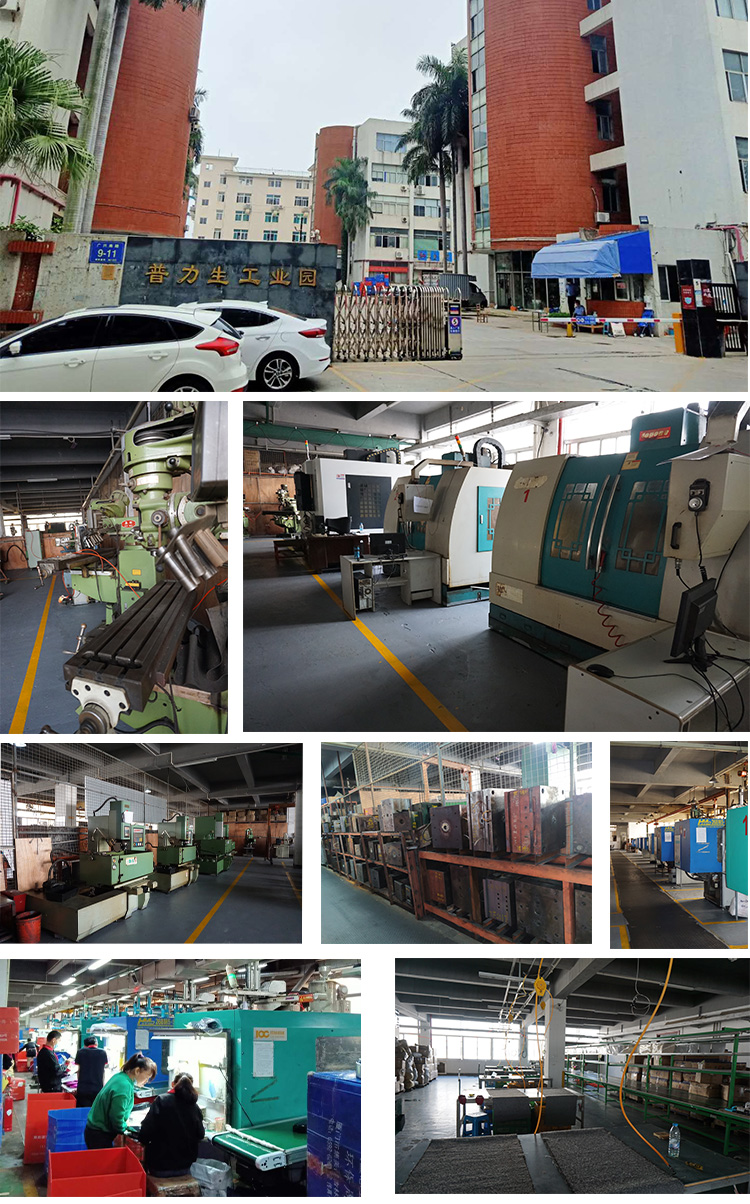

Plastic Housesholds Mould Manufacturer Information:

We were established in 2001 (Its formerly is Xiamen King trade Co., Ltd.). We are a manufacturer of Plastic injection mould and plastic products express in plastic parts of sport equipment. Now we are one of the important manufacturers in sport equipment industry. We also produce and sales plastic households products and plastic electronic products.

We are located in Xinglin development, Jimei district zone, Xiamen City. We have 20 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. Our workshop area is about 7500 square meters and we have precision production equipment which reach the international advanced level and the experienced technician. Now our production value can reach 1.4 Billion RMB. “Quality first, continuous improvement, respect individual, team spirit” is our top management objective. We will make “build quality brand, service the needs of customers” as our guiding ideology.

Product Qualification and Certificate: