Plastic Fitness Equipment Mould

-

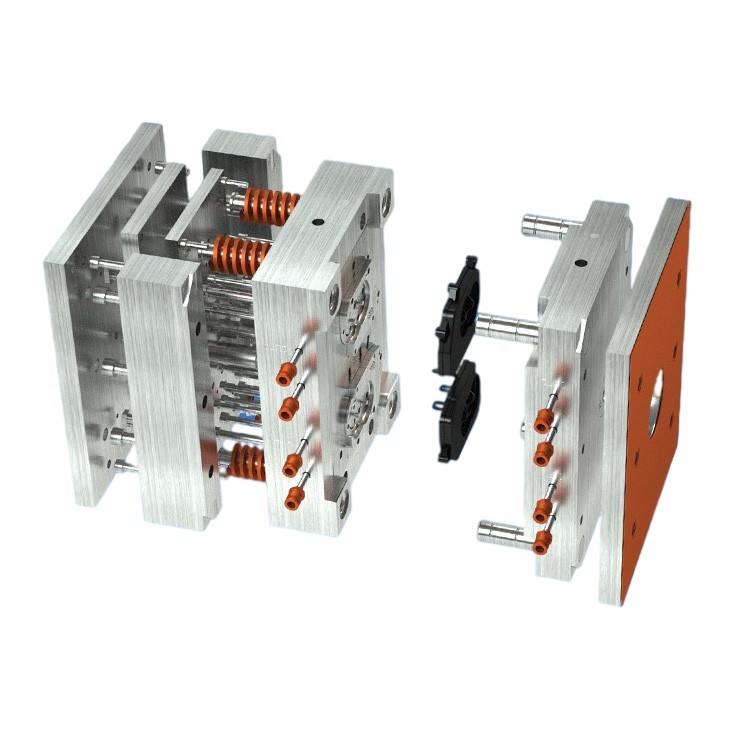

Plastic Injection Mould For Treadmill Parts

1. Rich Eexperience:

Email Details

with more than 15 years plastic injection mould industry experience

2. Customed Accepted:

OEM&ODM projects are highly welcomed, we have strong R&D team, can help modify drawings

3. Strict quality control:

1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out. -

Fitness Equipment Plastic Parts Injection Moulding

Plastic Injection Mould and Services:

Email Details

1. Products Designing & Manufacturing.

2. Rapid Prototyping

3. Plastic Moulds Designing & Manufacturing.

4. Plastic Injection Molding

5. Product Treatment & Product Assembling

6. OEM/ODM is welcomed. -

Hot

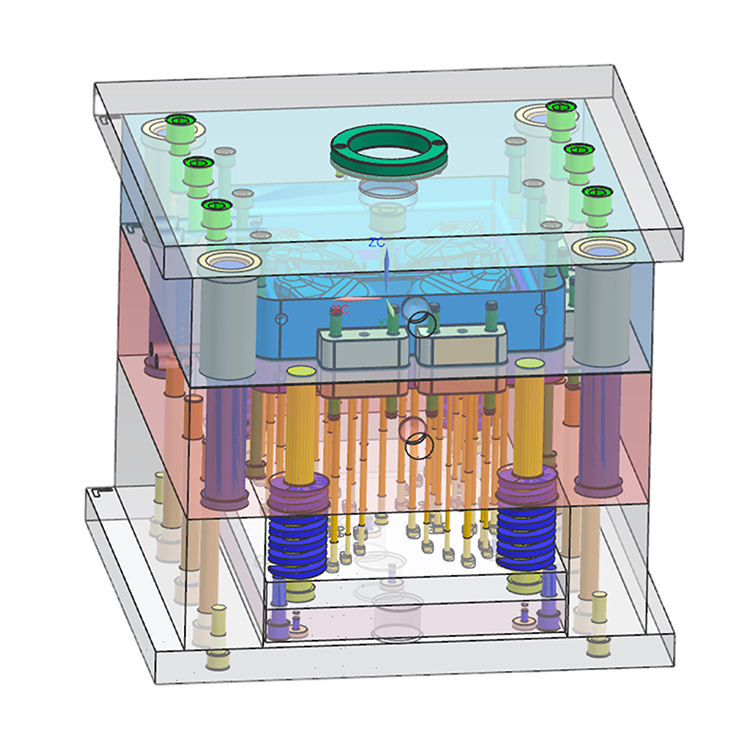

Fitness Equipment Mould Plastic Injection Molding

1. We can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

Email Details

2. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment;

3. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. -

Fitness Equipment Plastic Mold For Injection Spare Part

We can offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement.

Email Details

1. In the service of plastic injection, Ideal plastic is more than just an injection molder.

2. We provide solutions to manufacturing from start to finish.

3. Our expertise enables us to provide clients with superior product by providing the highest quality in design, development, and solutions for precision injection molding and related manufacturing.

4. We have over 15 years production experience.

5. Have more than 50 plastic injection mold machines, variety of precision mold produce equipment and spray printing equipment and more than 7500 square meters workshop. -

Walking Machine Molding Plastic Injection Mould

1. Have experience for mould;

Email Details

2. 3D Drawing service from plastic to plastic injection moulding tool design;

3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts;

4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts;

5. We have professional plastic injection mold tooling designer and plastic part producing line;

6. Plastic Injection Mould OEM & ODM Services;

7. ISO 9001, ISO 14001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory. -

Plastic Mould Injection Molding For Exercise Bike Parts

1. One-stop Service:

Email Details

Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services;

2. Rich Experience:

more than 15years experience for plastic injection mould and plastic injection and developing capability;

High Quality, Competitive Price and Fast Delivery Time

3. Advance Equipment:

Imported sophisticated production and testing equipment with high stability. -

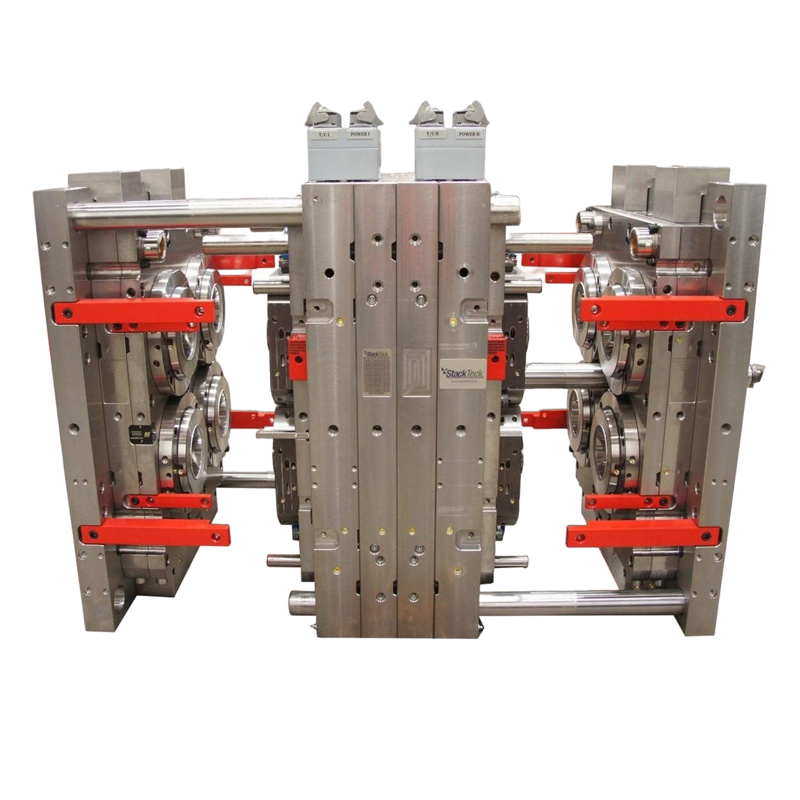

Indoor Sports Equipment Plastic Injection Mould

1. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

Email Details

2. Provide high-volume injection molding solutions;

3. With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

4 With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment;

5. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts. -

Treadmill Plastic Accessories Injection Mold

1. One-stop Service:

Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services;

2. Rich Experience:

more than 15years experience for plastic injection and developing capability and more than 800 moulds making experience

3. High Quality, Competitive Price and Fast Delivery Time:

We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment,

more than 10 engineers and about 7500 square meters workshop area

4. Advance Equipment:

Imported sophisticated production and testing equipment with high stability, such as, High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine from 60-950T available.Plastic Accessories Injection Mold Plastic Accessories Mold Treadmill Plastic Accessories Injection MoldEmail Details -

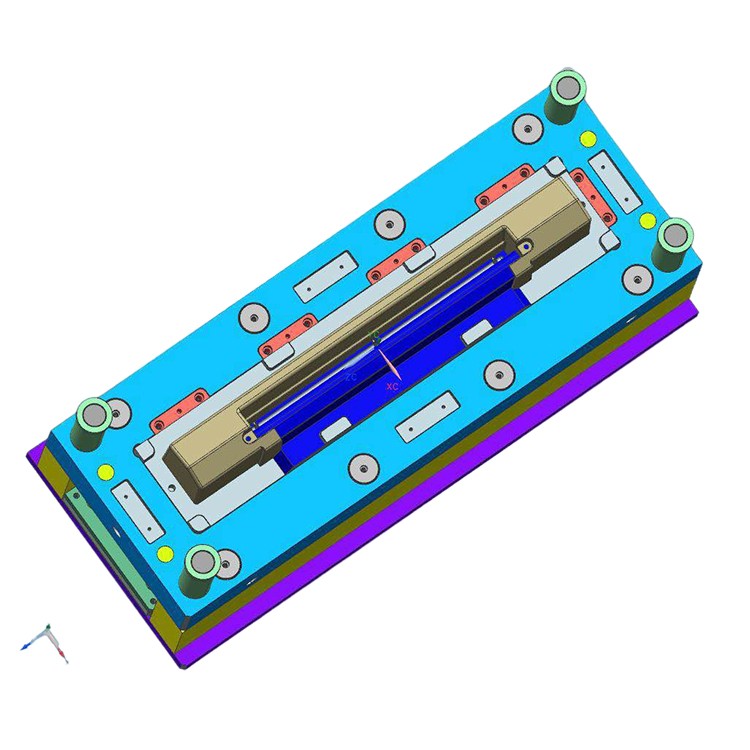

Custom Plastic Injection Parts Mould For Sport Equipment

1. Durable and long service life

Email Details

50k-500k shots, according to the requirement of the products and the raw material;

2. Quick maintenance to keep the mold clean and neat

Do mold maintenance to sure the plastic mold clean and neat;

There are three points that is important to plastic injection maintenance:

First, daily maintenance: For all kinds of moving parts, such as, ejector pin, slide, guiding post, oil for guiding bush, mould surface cleaning and water line dredging that must maintain everyday when producing;

Second, regular maintenance: Beside the daily maintenance, the regular maintenance includes the cleaning of the exhaust slot the air trapped and the black level and the exhaust, and the correction of damage and wear parts etc.

Third, appearance maintenance: Painting outside of the plastic injection mould to avoid rust. When lowering the plastic injection mould, the fixed and movable mould must be coated with anti-rust oil. The mold must be closed tightly to prevent dust going to the cavity.