Fitness Equipment Plastic Parts Injection Moulding

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

Plastic Injection Mould and Services:

1. Products Designing & Manufacturing.

2. Rapid Prototyping

3. Plastic Moulds Designing & Manufacturing.

4. Plastic Injection Molding

5. Product Treatment & Product Assembling

6. OEM/ODM is welcomed.

Fitness Equipment Plastic Parts Injection Moulding

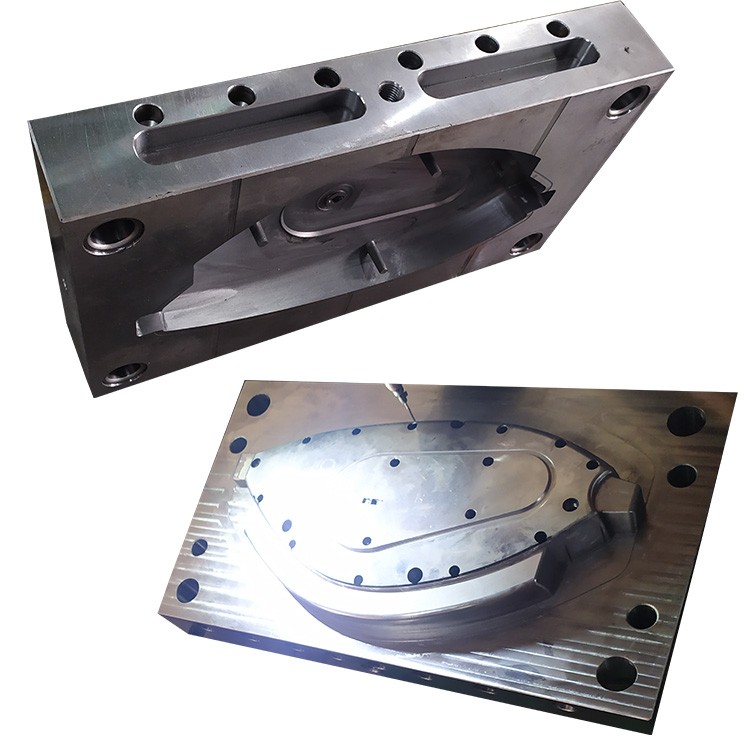

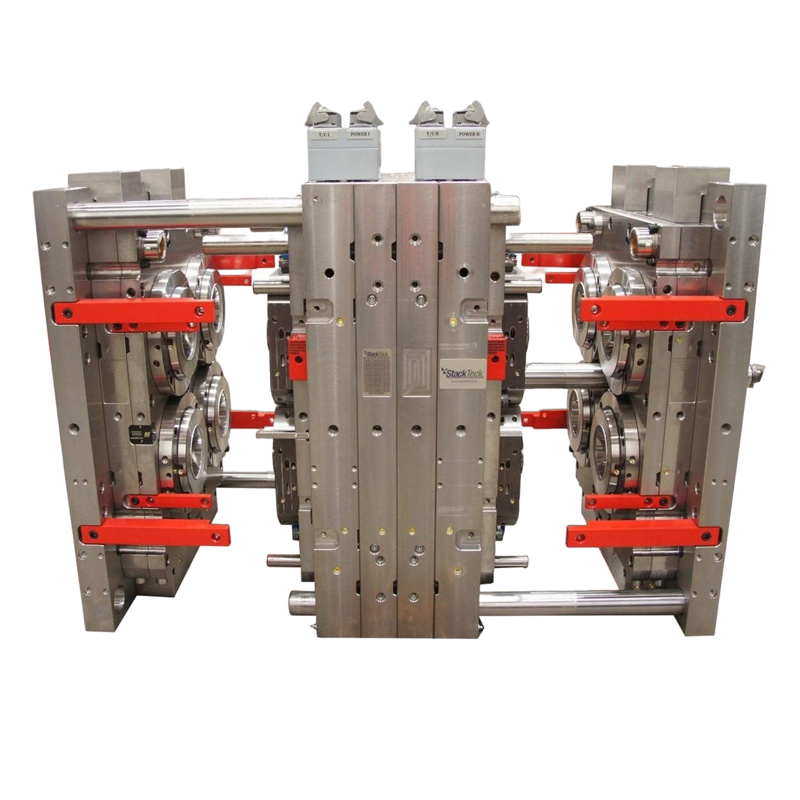

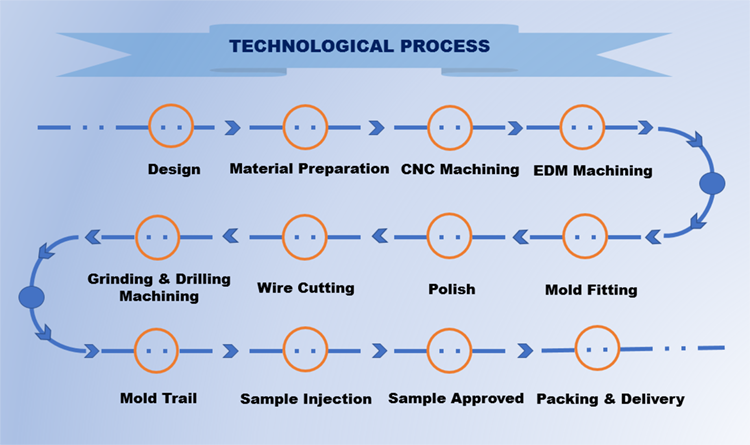

Mould process machines:

CNC, EDM, wire-cutting machine, milling machine, lathe machine, drilling machine, grinding machine, polishing machine, CMM, etc.

OEM and ODM Manufacturing

1. Silk Screen print: better for 1-2 colors design

2. Label/sticker: colorful based background, better for more than 3 colors design.

3. Plastic label/sticker: clear or white based b. ground, better for 1-3 colors design

4. Paper box or your own packaging could also be changed according to your design

5. New moulds, new style or shape welcome

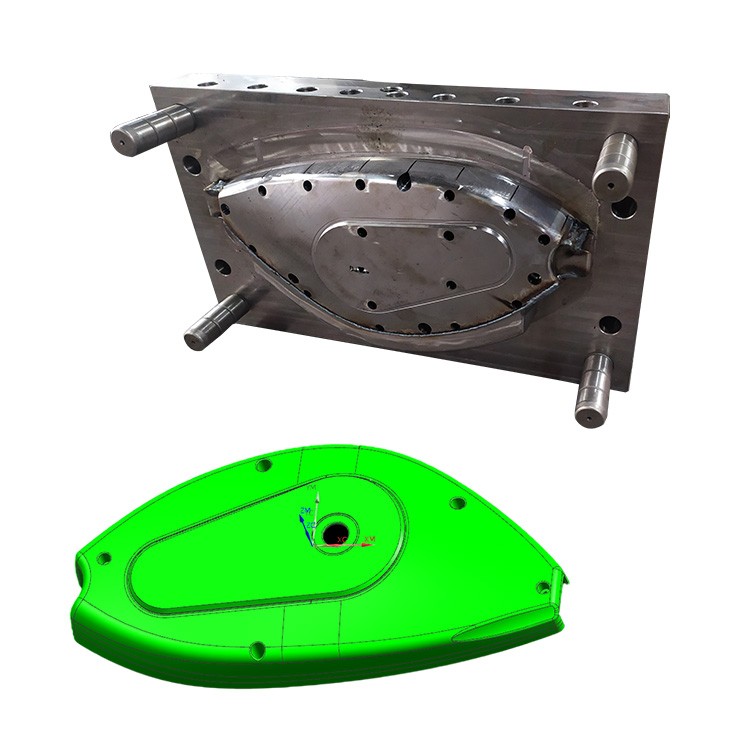

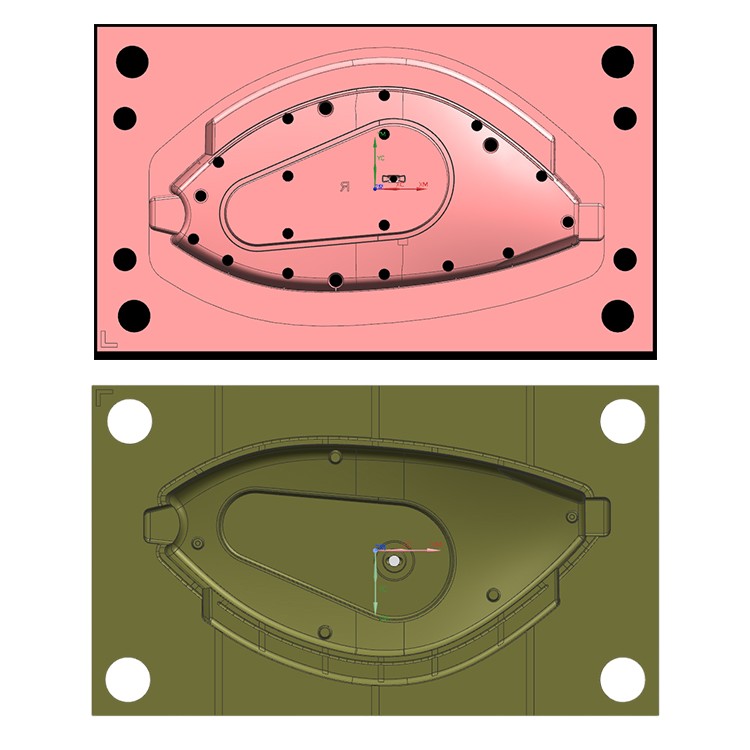

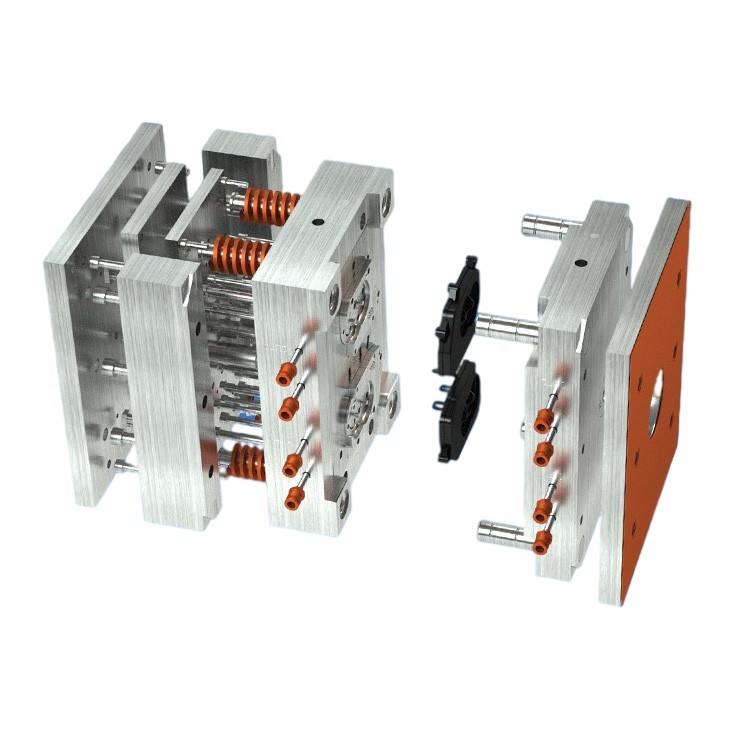

Plastic Fitness Equipment Mould Description:

Mould Base | DME, SD, LKM, HASCO and so on |

Mold Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Mold Accuracy | +/-0.001mm |

Runner System | Hot runner/Cold runner or combined |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 60 TO 950ton Horizontal injection machines |

Surface Treatmetn | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

Product Name | Fitness Equipment Plastic Parts Injection Moulding |

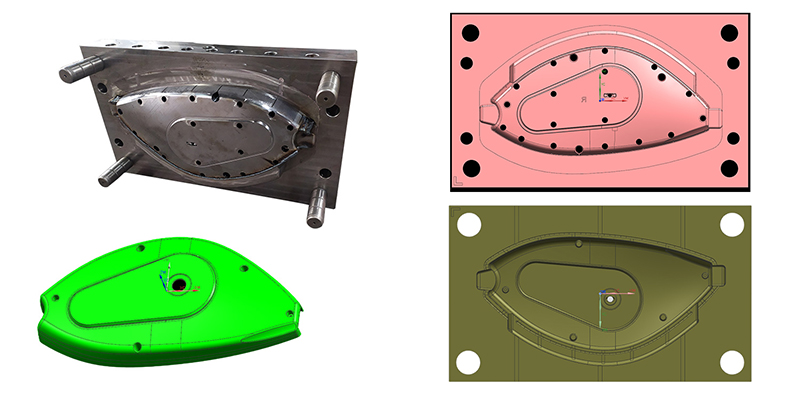

Plastic Fitness Equipment Mould and Products Show:

Plastic Fitness Equipment Mould Processing Flow:

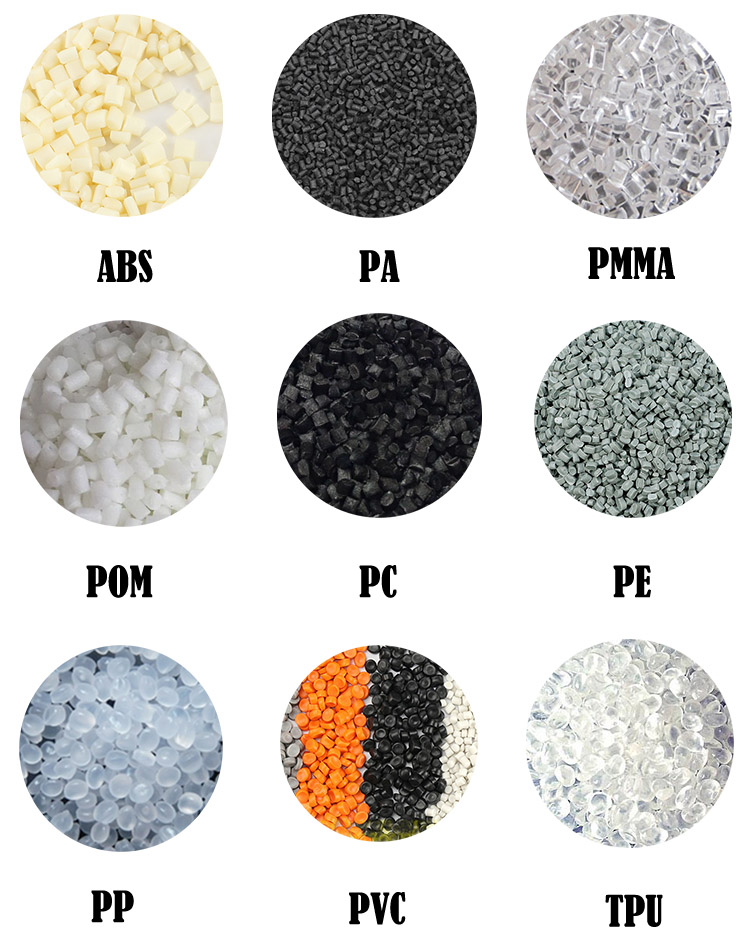

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, PC, POM, PPS, PC, PPE, PPO, etc.

Certificate:

Packing and Shipping: