Fitness Equipment Plastic Mold For Injection Spare Part

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

We can offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement.

1. In the service of plastic injection, Ideal plastic is more than just an injection molder.

2. We provide solutions to manufacturing from start to finish.

3. Our expertise enables us to provide clients with superior product by providing the highest quality in design, development, and solutions for precision injection molding and related manufacturing.

4. We have over 15 years production experience.

5. Have more than 50 plastic injection mold machines, variety of precision mold produce equipment and spray printing equipment and more than 7500 square meters workshop.

Fitness Equipment Plastic Mold for Injection Spare Part

Plastic Fitness Equipment Mould Description:

Mould Base | DME, SD, LKM, HASCO and so on |

Mold Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Mold Accuracy | +/-0.001mm |

Mold Life | 50K-1.5Million Shots |

Inspection | IQC, IPQC, FQC,QA |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 60 TO 950ton Horizontal injection machines |

Product Name | Fitness Equipment Plastic Mold for Injection Spare Part |

Surface Treatmetn | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

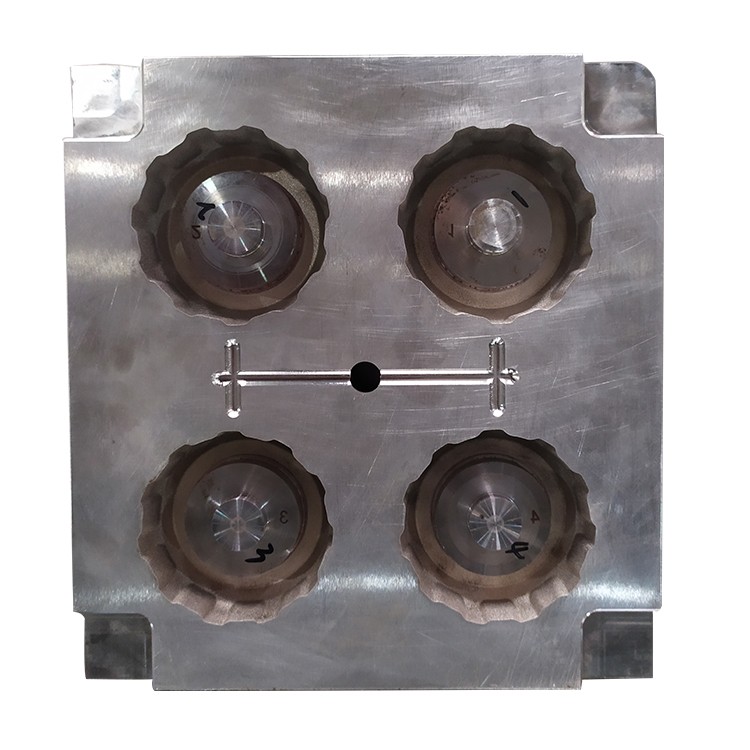

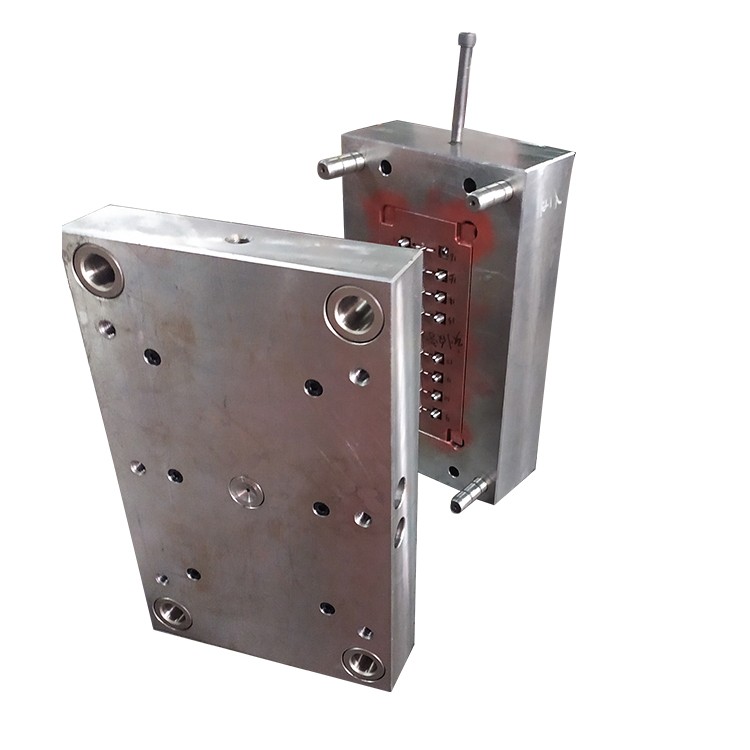

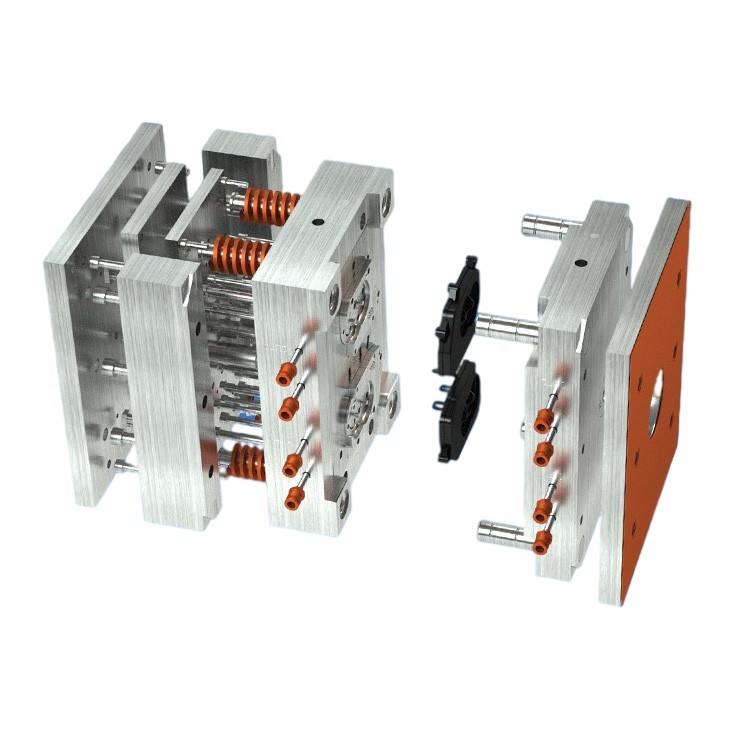

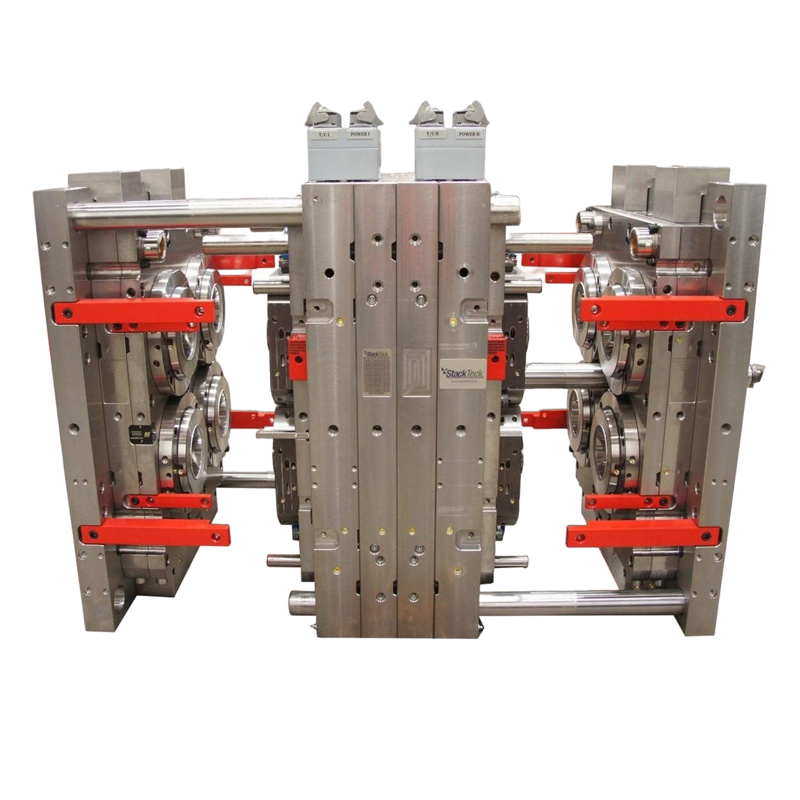

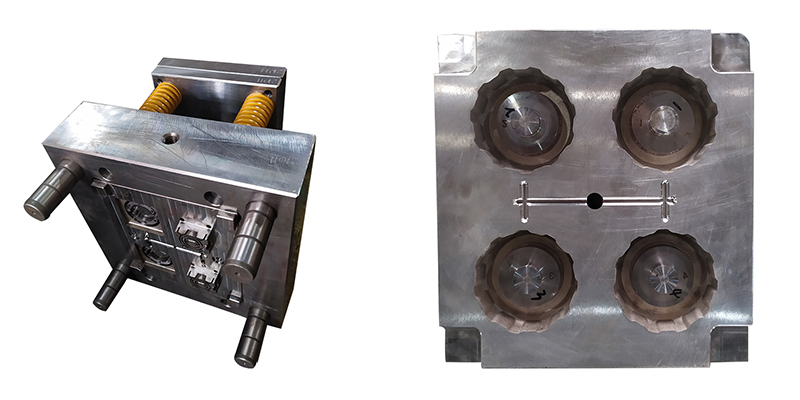

Plastic Fitness Equipment Mould and Products Show:

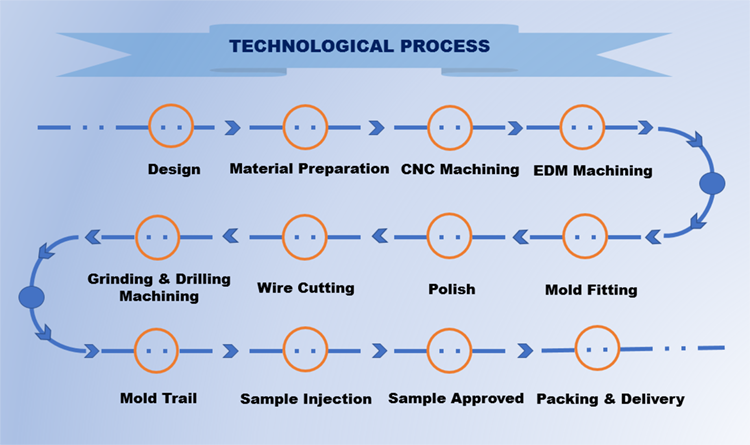

Plastic Fitness Equipment Mould Processing Flow:

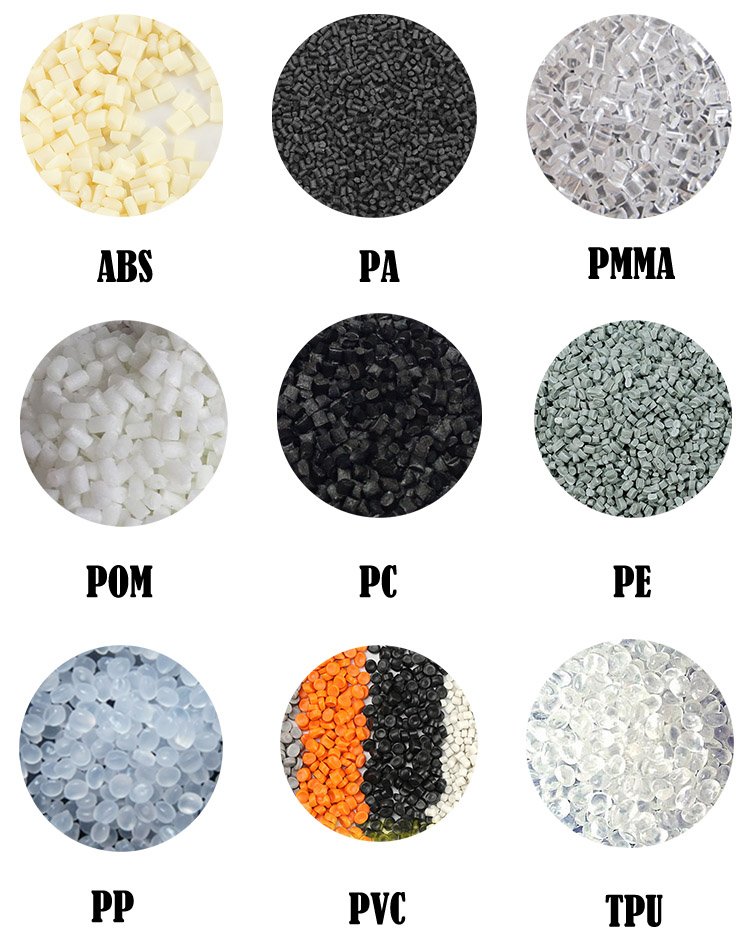

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, PBT, PC, ABS, POM, PPS, PC, , etc.

Certificate:

Exhibition:

Every year we attend China Sport exhibition in Shanghai.

Packing and Shipping:

FAQ:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection. Sometimes we also make Die casting mold and stamping molds according to our customer’s requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, we can provide steel certificate or hardness certificate to prove.

Q5: Can you make the texture / text / heat treatment /nitriding for the plastic injection mold?

A5: Yes, as plastic mold factory, we have long term cooperated subsidiary factories that do those processes. They are professional and well reputed in our local market.