Custom Plastic Injection Parts Mould For Sport Equipment

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. Durable and long service life

50k-500k shots, according to the requirement of the products and the raw material;

2. Quick maintenance to keep the mold clean and neat

Do mold maintenance to sure the plastic mold clean and neat;

There are three points that is important to plastic injection maintenance:

First, daily maintenance: For all kinds of moving parts, such as, ejector pin, slide, guiding post, oil for guiding bush, mould surface cleaning and water line dredging that must maintain everyday when producing;

Second, regular maintenance: Beside the daily maintenance, the regular maintenance includes the cleaning of the exhaust slot the air trapped and the black level and the exhaust, and the correction of damage and wear parts etc.

Third, appearance maintenance: Painting outside of the plastic injection mould to avoid rust. When lowering the plastic injection mould, the fixed and movable mould must be coated with anti-rust oil. The mold must be closed tightly to prevent dust going to the cavity.

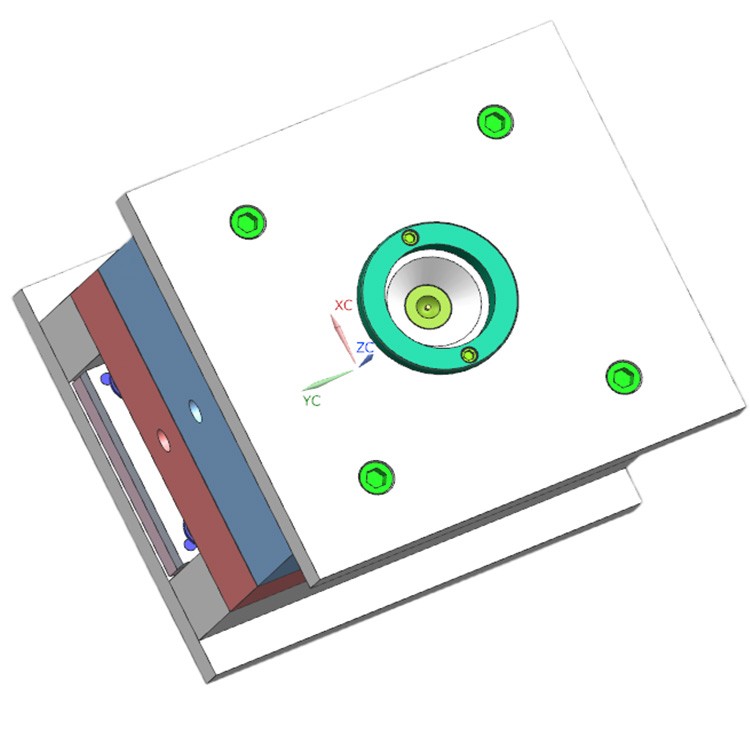

Custom Plastic Injection Parts Mould for Sport Equipment

Plastic Fitness Equipment Mould Description:

Mould Name | Custom Plastic Injection Parts Mould For Sport Equipment |

Mold Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Tolerance | +/-0.001mm |

Mold Life | 50K-500K Shots |

Sprue gate | Hot runner/Cold runner or combined |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 60 TO 950ton Horizontal injection machines |

Plasitc Material | PA6, PA66, ASA, POM, PPS, ABS, ABS+GF, ABS/PC, POM(Derlin), PP, PE, PC, PMMA(Acrylic), PVC, PEI, PBT, PTFI… |

Surface Treatmetn | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

Certificates | ISO 9001 |

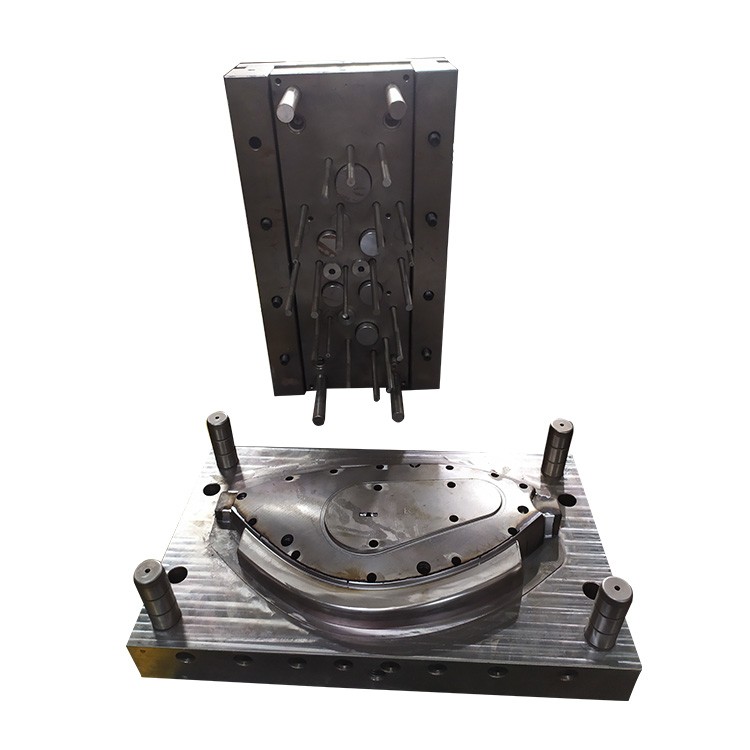

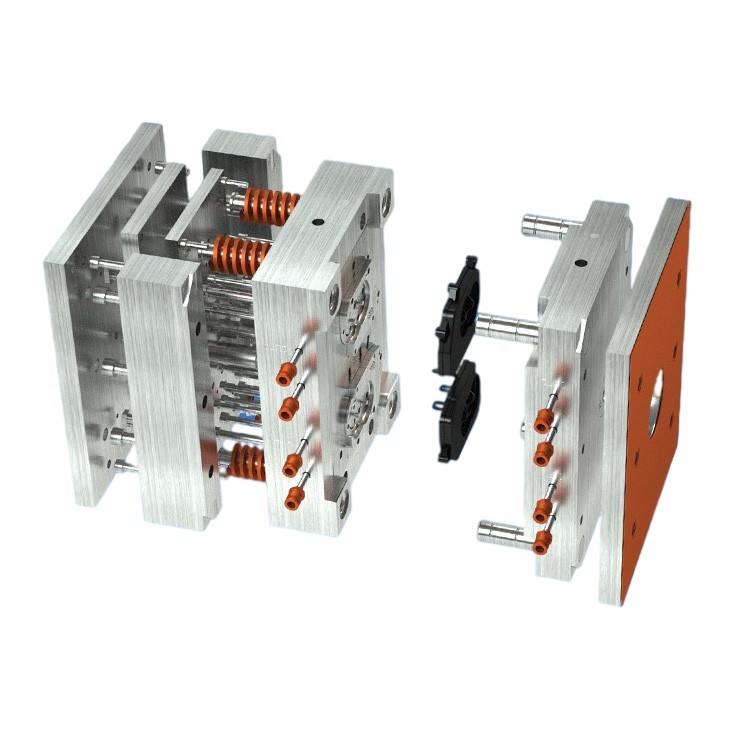

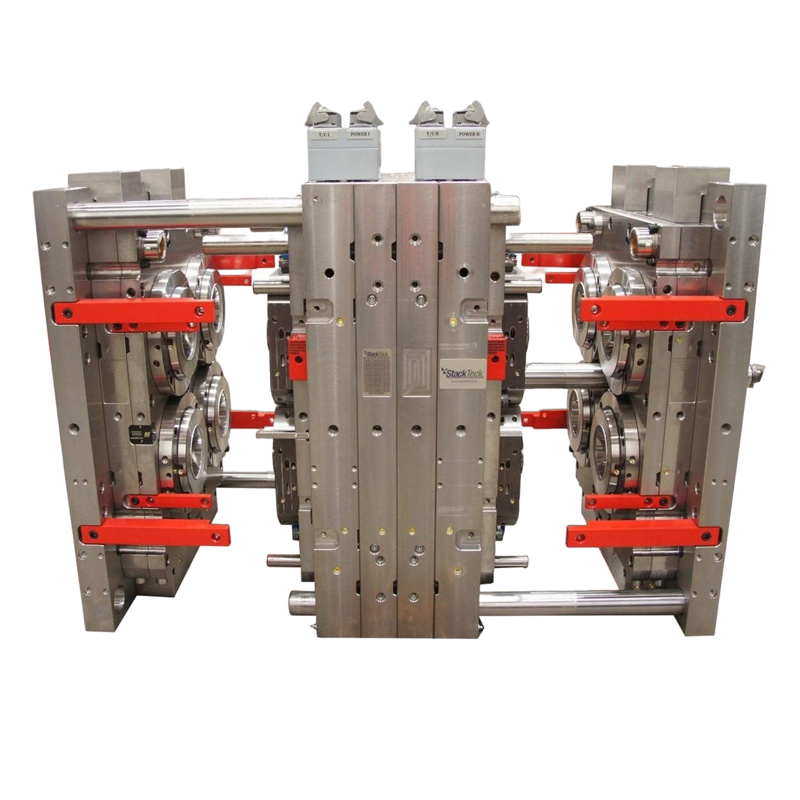

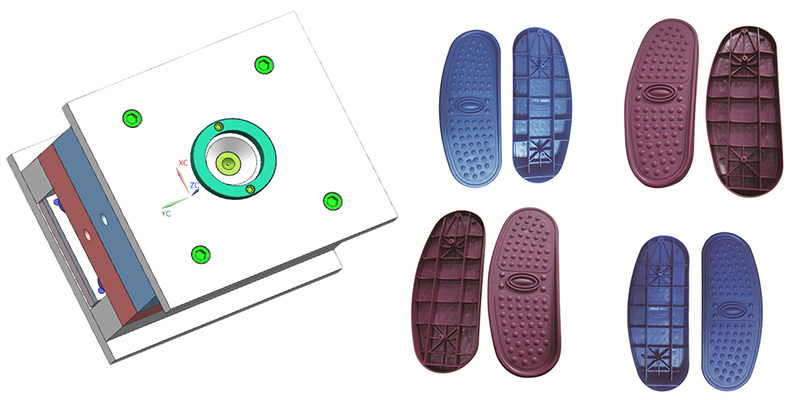

Plastic Fitness Equipment Mould and Products Show:

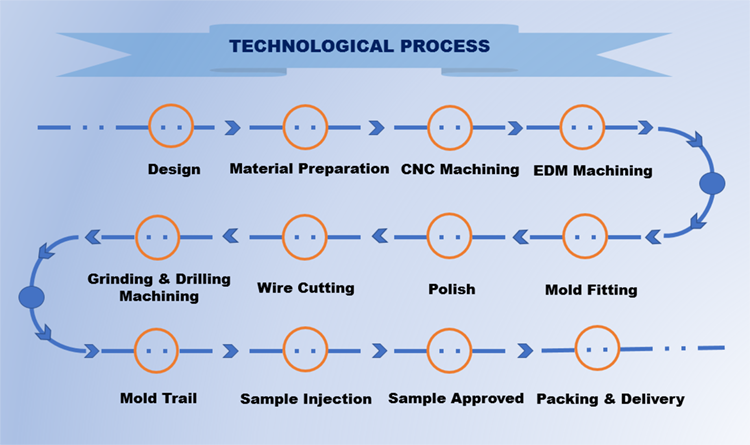

Plastic Fitness Equipment Mould Processing Flow:

Exhibition:

Every year we attend China Sport exhibition in Shanghai.

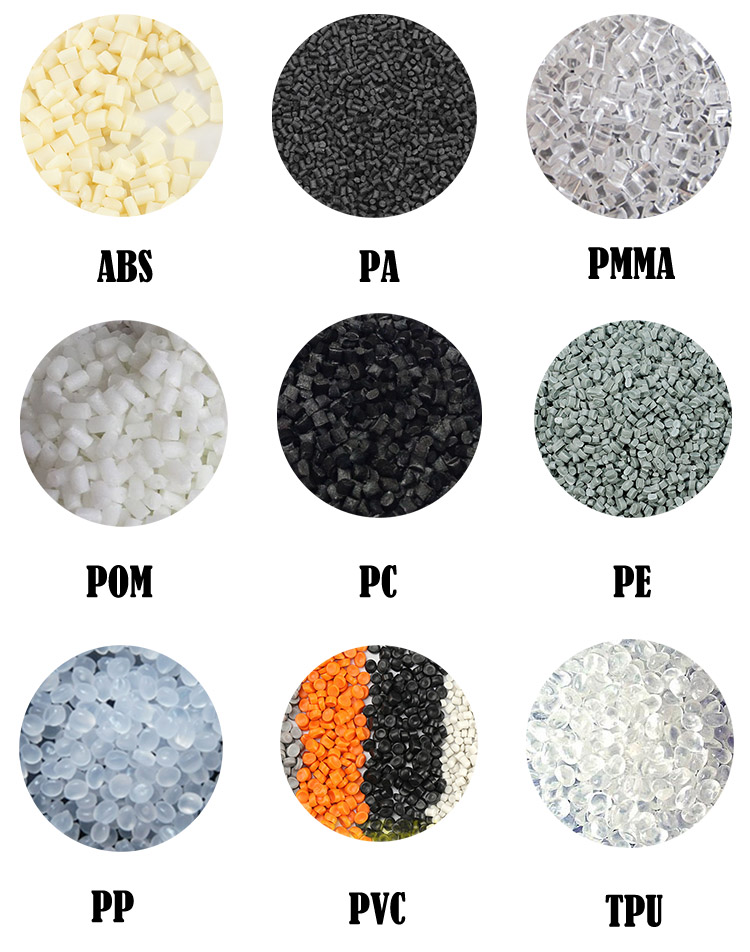

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Certificate:

Packing and Shipping:

FAQ:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection. Sometimes we also make Die casting mold and stamping molds according to our customer’s requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, we can provide steel certificate or hardness certificate to prove.

Q5: How long is the lead-time for a plastic injection mold?

A5: It all depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.