Custom Plastic Mold Plastic Products Injection Parts

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. We have excellent comprehensive performance and can replace traditional materials such as metal and ceramic in many special fields.

2. The high temperature resistance, self-lubrication, wear resistance and fatigue resistance of this plastic make it one of the most popular high-performance engineering plastics.

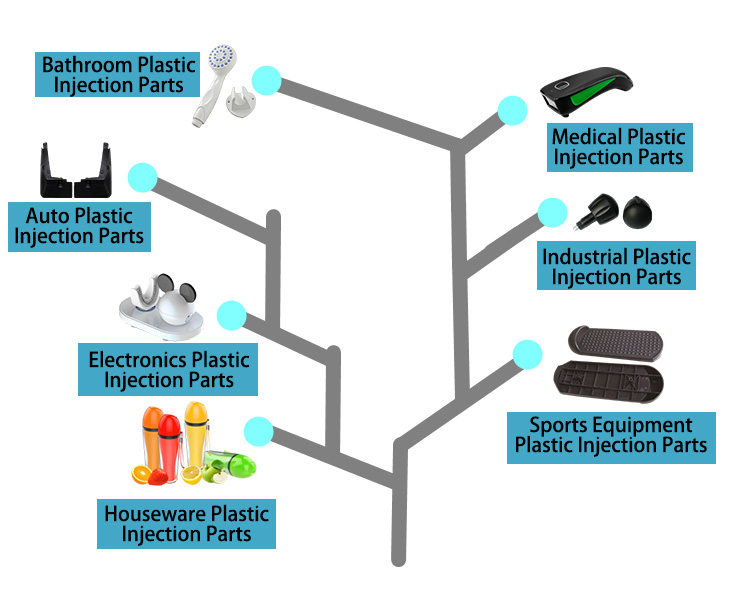

3. Application fields: we engineering plastics are widely used in electronics, household, fitness equipment, machinery, chemical industry, automobile and other high-tech industrial fields.

Custom Plastic Mold Plastic Products Injection Parts

Plastic Injection Products Specification:

Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc. (Hardness 35~55HRC) |

Shaping mode | Plastic injection mold |

Product name | Custom Plastic Mold Plastic Products Injection Parts |

Runner | Hot/cold |

Ejection system | Motor/hydraulic cylinder/stripping plate/angle pin, etc. |

Cooling system | In core baffle and in cavity plate chain drilling type cooling |

Design software | UG, PROE, CAD, CAXA etc. |

Plastic material | ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc. |

Surface treatment | Polish, texture, sand blasting, chrome plating |

Application | Fitness equipment plastic injection mold and parts |

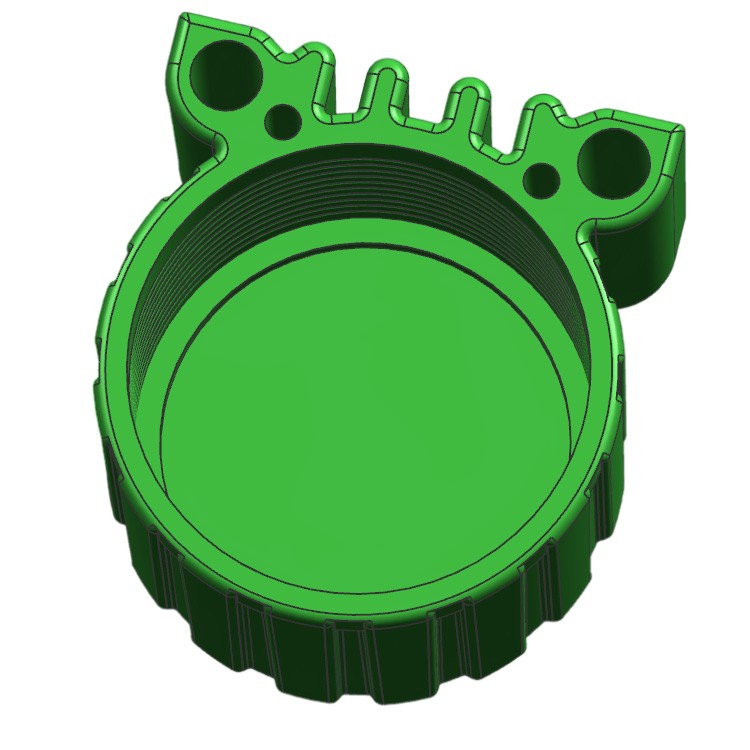

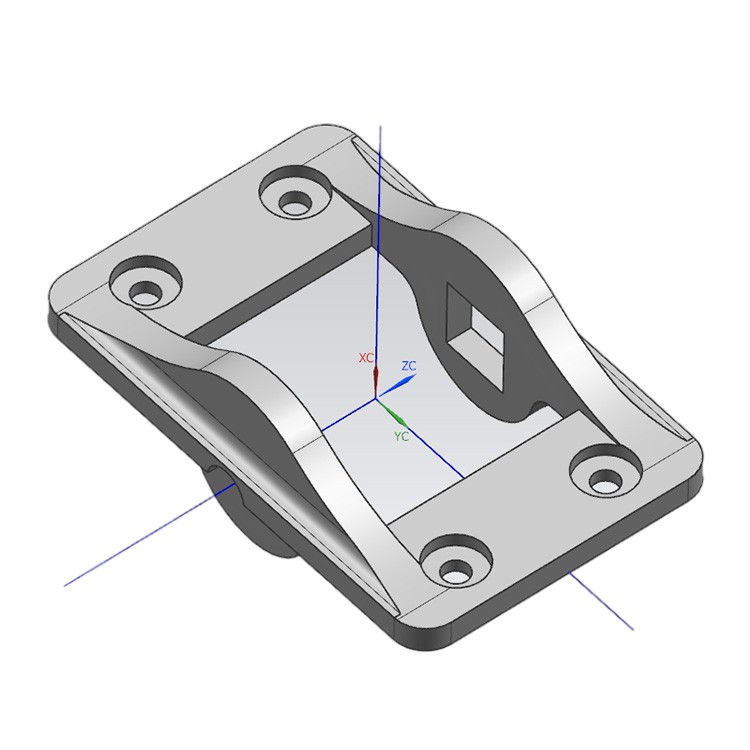

Plastic Injection Products Picture:

Plastic Injection Products Feature:

1. Efficiency production and automotive operation;

2. Shape can be from simple to complex, the size can be from large to small and the product size is accurate;

3. It is used in the forming and processing fields of mass production and products with complex shapes.

Payment and Shipping:

We accept many kinds of the payment, the details as the following:

1. For the samples, we can accept PayPal, West Union and Bank Transfer as the payment, and will ship the samples by air express, such as the DHL, UPS and FEDEX.

2. For the bulk order, we can suggest the bank transfer as the payment method with the 30% deposit, we will ship out the goods according to the choice from the customers for shipping.

3. We can ensure the shipping is fast and efficient.

FAQ About Molded Products:

Q1: How many injection plastic mouldings machines do you have?

A1: We have more than 50 sets of plastic Injection Mouldings machines.

Q2: what is the minimum & maximum unit weight and size your machines can produce?

A2: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q3: What kind of plastic materials you usually use?

A3: We are specialized in producing plastic products with the following materials: PP, ABS, PC, POM, PA, HDPE, HIPE, PS, AS, PBT, PET, PMMA, PVC and so on.