custom plastic injection

-

Custom Plastic Mold Plastic Products Injection Parts

1. We have excellent comprehensive performance and can replace traditional materials such as metal and ceramic in many special fields. 2. The high temperature resistance, self-lubrication, wear resistance and fatigue resistance of this plastic make it one of the most popular high-performance engineering plastics. 3. Application fields: we engineering plastics are widely used in electronics, household, fitness equipment, machinery, chemical industry, automobile and other high-tech industrial fields.

Plastic Mold Plastic Products Plastic Mold Injection Parts Custom Plastic Injection Plastic Products Injection PartsEmail Details -

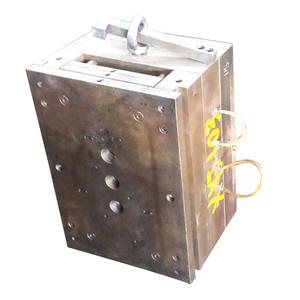

Precision Custom Plastic Injection Mould

1). Quickly response and complete understanding 2). The most competitive and reasonalbe price 3). Short delivery time and prompt delivery 4). Well and High Quality Control 5). Customer's Designs and Logos are welcome 6). Enough and advance machines and equipments.

Precision Custom Mold Precision Plastic Injection Mold Precision Custom Plastic Mold Precision Custom Plastic Injection MoldEmail Details -

Custom Plastic Injection Mold For Industrial Parts

1. High quality and factory price for plastic injection mould service; 2. Plastic injection mould design and making service and plastic injection service for over 30 countries; Provide high-volume injection molding solutions; 3. One-stop service from plastic injection mould making to plastic injection and assembly;

Custom Plastic Injection Mold Injection Mold for Industrial Parts Plastic Injection Mold for Industrial Parts Custom Mold for IndustrialEmail Details -

Plastic Mould Custom Plastic Injection Parts

1. Have more than 15 year experience in plastic injection produce. 2. 3D Drawing service from plastic injection products design and plastic injection mould design. 3. 2 special after sales team to help you solve any problem for plastic injection parts. 4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic injection parts. 5. We have professional plastic injection mold tooling designer and advance plastic part producing line.

Email Details -

Custom Molding Plastic Injection Products

One-stop service: provides service of part design, prototype making, mold design, mold production, mass production and assembly service in house. We are cooperating with many clients all over the world and have a deep understanding of the mold industry, our experience range from simple design to challenging technical parts. Quality Guarantee: free plastic injection mold maintains service and a strict quality control process.

Plastic Injection Custom Injection Custom Plastic Injection Products Custom Molding Plastic ProductsEmail Details -

Custom Plastic Injection Parts Mould For Sport Equipment

1. Durable and long service life 50k-500k shots, according to the requirement of the products and the raw material; 2. Quick maintenance to keep the mold clean and neat Do mold maintenance to sure the plastic mold clean and neat; There are three points that is important to plastic injection maintenance: First, daily maintenance: For all kinds of moving parts, such as, ejector pin, slide, guiding post, oil for guiding bush, mould surface cleaning and water line dredging that must maintain everyday when producing; Second, regular maintenance: Beside the daily maintenance, the regular maintenance includes the cleaning of the exhaust slot the air trapped and the black level and the exhaust, and the correction of damage and wear parts etc. Third, appearance maintenance: Painting outside of the plastic injection mould to avoid rust. When lowering the plastic injection mould, the fixed and movable mould must be coated with anti-rust oil. The mold must be closed tightly to prevent dust going to the cavity.

Custom Plastic Injection Parts Mould Custom Injection Parts Mould Custom Plastic Parts Mould Plastic Mould for Sport EquipmentEmail Details -

Custom Plastic Injection Mould For Plastic Products

1. One-stop Solution: Can provide one-stop service from mold design, mold making, machining, surface, injection production, screen printing, spray paint, assembly, packing to shipping; 2. Quality Guarantee: We have a professional team and strict quality management system to control the quality. And experienced engineers, precision machines, CMM and closed-loop QC system; 3. Customer Service: With more than 10 engineers for mold design, programming and project managers. We are using CAD/CAE/CAM software to do the design, analysis & programming.And every client is served by a specialized sales for timely technical support and after-sales service.

Custom Plastic Injection Mould Mould for Plastic Products Custom Mould Custom Mould for Plastic ProductsEmail Details -

Custom Plastic Injection Molding For Plastic Parts

1. Free reference quotation with DFM 2. Free consult services 3. Free mould trial for 3times 4. Free part design improve if make moulds/project in AE 5. Free maintenance for in house production mold with tooling life. 6. Signed Non Disclosure Agreement before work 7.1 key contact, 1 team back-support always 8. Well management and precision quality ensure 9. Over 15 years' expertise since 2005 10.7/24 services for on time delivery

Email Details