custom injection

-

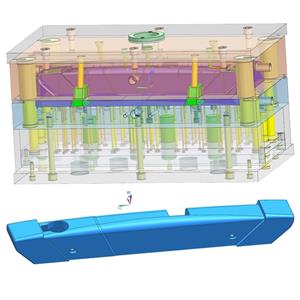

Custom Plastic Products Molding Injection Mould

Provide high quality custom plastic injection molded parts; Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET etc.; Different injection molded parts can pass different certification such as UL test, V0 fire resistant test, FDA test, REACH test, SGS test and IP65; Provide different surface treatment for injection molded parts. Commonly use surface treatment for injection molded parts as: Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI; Besides making injection molded parts, we also provide printing, welding, assembly and packing service;

Email Details -

Custom Injection Moulding Plastic Mould

1. Design Service: With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers. 2. Guaranteed delivery: (1) Have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. (2) Our workshop area is about 7500 square meters; (3) Provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 3. Strict quality management system: (1) Material inspection--Check the material surface and roughly dimension. (2) Production first inspection--To ensure the critical dimension in mass production. (3) Sampling inspection--Check the quality before sending to the warehouse. (4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

Email Details -

High Precision Custom Injection Plastic Parts

1.Product engineering, development, consultation and the latest in manufacturing simulation software. 2. A strong dedicated workforce committed to promoting and customer service. 3. Collaboration during the mold design process between our customers, management, and our employees to implement the best possible concept. 4. Our unique capacity to create solutions that replace expensive, fabricated steel products. 5. Provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

Injection Plastic Precision Injection Plastic Custom Injection Plastic Precision Custom Injection PartsEmail Details -

Custom Plastic Injection Molding Products

We are a professional manufacturer for plastic injection products and custom molding with competitive price and good quality since 2007. Our Service: 1. Plastic injection molding & Plastic products 2. Custom CNC machining parts service 3. Design service (OEM service) We could control the quality and the cost very well by our own equipment, such as WEDM-LS, WEDMHS, grinding machine, milling & turning machine, CNC center, wire cutting, bending machine, injection machines, vulcanization machine...etc.

Custom Plastic Products Custom Injection Products Injection Molding Products Plastic Molding ProductsEmail Details -

Plastic Auto Parts Molding Custom Injection Mold

1. Good experience in mould making since the year of 2008. 2. Machinery core pulling system save cost and increase production efficiency. 3. Perfect core pulling distance within 180mm. 4. Excellent R&D team.(We can offer you 3D mould design with all details within one day.) 5. Efficiency production, we can finish Push-Fit fitting mould of size 110mm in two cavity with in 45days.) 6. Competitive price in save level of mould manufactuers.

Custom Injection Mold Auto Parts Custom Injection Mold Plastic Custom Injection Mold Auto Parts Custom MoldEmail Details -

Plastic Mould Custom Plastic Injection Parts

1. Have more than 15 year experience in plastic injection produce. 2. 3D Drawing service from plastic injection products design and plastic injection mould design. 3. 2 special after sales team to help you solve any problem for plastic injection parts. 4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic injection parts. 5. We have professional plastic injection mold tooling designer and advance plastic part producing line.

Email Details -

Custom Made ABS Injection Plastic Parts

Plastic mold and plastic injection services are including: 1. Plastic product and plastic injection mold design and development, both ODM and OEM; 2. Scanning data: Get 3D drawing if you only offer the sample for plastic injection mold making; 3. Drawing re-construction; 4. Prototype making; 5. Tooling/Mold setup and trial shot; 6. Injection molding for the plastic parts. 7. Mass production

Injection Plastic Parts ABS Injection Plastic Parts Custom Injection Plastic Parts ABS Injection PartsEmail Details -

Custom Molding Plastic Injection Products

One-stop service: provides service of part design, prototype making, mold design, mold production, mass production and assembly service in house. We are cooperating with many clients all over the world and have a deep understanding of the mold industry, our experience range from simple design to challenging technical parts. Quality Guarantee: free plastic injection mold maintains service and a strict quality control process.

Plastic Injection Custom Injection Custom Plastic Injection Products Custom Molding Plastic ProductsEmail Details -

Custom Plastic Injection Parts Mould For Sport Equipment

1. Durable and long service life 50k-500k shots, according to the requirement of the products and the raw material; 2. Quick maintenance to keep the mold clean and neat Do mold maintenance to sure the plastic mold clean and neat; There are three points that is important to plastic injection maintenance: First, daily maintenance: For all kinds of moving parts, such as, ejector pin, slide, guiding post, oil for guiding bush, mould surface cleaning and water line dredging that must maintain everyday when producing; Second, regular maintenance: Beside the daily maintenance, the regular maintenance includes the cleaning of the exhaust slot the air trapped and the black level and the exhaust, and the correction of damage and wear parts etc. Third, appearance maintenance: Painting outside of the plastic injection mould to avoid rust. When lowering the plastic injection mould, the fixed and movable mould must be coated with anti-rust oil. The mold must be closed tightly to prevent dust going to the cavity.

Custom Plastic Injection Parts Mould Custom Injection Parts Mould Custom Plastic Parts Mould Plastic Mould for Sport EquipmentEmail Details