injection mould

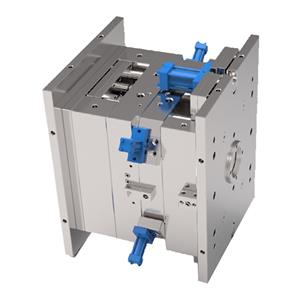

-

Plastic Injection Mould For Treadmill Parts

1. Rich Eexperience: with more than 15 years plastic injection mould industry experience 2. Customed Accepted: OEM&ODM projects are highly welcomed, we have strong R&D team, can help modify drawings 3. Strict quality control: 1). Materials inspection by IQC; 2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production; 3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects; 4). FQC will check the products before sending to the warehouse; 5). 100% inspected by OQC before shipping out.

Plastic Mould for Treadmill Parts Injection Mould for Treadmill Parts Mould for Treadmill Parts Plastic Injection Treadmill PartsEmail Details -

Customzied Electronics Plastic Injection Mould

For Plastic Injection Mould: 1. High quality raw material to ensure the high quality of the plastic injection mould; 2. Fast delivery, if the sample plastic injection mould, we can finish in 10days; 3. More than 800 mould making experience; For Plastic Injection Products: With more than 15years experience and more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment to ensure the quality and quantity;

Electronics Plastic Injection Mould Customzied Plastic Mould Customzied Plastic Injection Mould Customzied Electronics MouldEmail Details -

Plastic Injection Households Mould For Storage Box

1. With more than 7500 squar meter workshop for plastic injection mould and the plastic injection products; 2. With 60T to 950T plastic injection machines to run the mold test and mass production for customers; 3. With rich experience for plastic injection mould and plastic injection since 2005; 4. Precision production equipment and machines which reach the international advanced level and the experienced technician for the plastic injection mold and plastic producets; 5. ISO 9001 Certified for plastic injection mould and plastic injection products and our factory;

Injection Households Mould Plastic Injection Households Mould Plastic Households Mould Plastic Mould for Storage BoxEmail Details -

ABS/PC Auto parts mold

Product name: Auto parts mold Molding machine: 800 tons Mold core material: 1CAV Plastic material: PC+ABS Mold life: 500,000 mold times Quality system: ISO9001 Cooperation model: customization according to drawings, ODM, OEM

Auto Plastic Mould Spare Parts Injection Mould Spare Parts Injection Auto Plastic Mould Spare Parts Injection Plastic MouldEmail Details -

Fitness Equipment Plastic Parts Injection Moulding

Plastic Injection Mould and Services: 1. Products Designing & Manufacturing. 2. Rapid Prototyping 3. Plastic Moulds Designing & Manufacturing. 4. Plastic Injection Molding 5. Product Treatment & Product Assembling 6. OEM/ODM is welcomed.

Parts Injection Moulding Fitness Equipment Injection Moulding Fitness Injection Moulding Fitness Plastic Injection MouldingEmail Details -

Hot

Plastic Injection Mould for Bathroom Products

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. 2. Our workshop area is about 7500 square meters; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;

Email Details -

Custom Plastic Products Molding Injection Mould

Provide high quality custom plastic injection molded parts; Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET etc.; Different injection molded parts can pass different certification such as UL test, V0 fire resistant test, FDA test, REACH test, SGS test and IP65; Provide different surface treatment for injection molded parts. Commonly use surface treatment for injection molded parts as: Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI; Besides making injection molded parts, we also provide printing, welding, assembly and packing service;

Email Details -

Car Lampshade Molding

1. High-strength material: high-strength materials are used to improve the impact resistance and deformation resistance of the lampshade. 2. Weather resistance: After special treatment, it has good weather resistance and can adapt to various harsh climatic conditions. 3. High light transmittance: unique design, improve light transmittance, and ensure lighting effect. 4. Personalized customization: According to customer needs, personalized customization services can be provided to meet the needs of different models and appearance designs.

Email Details -

Cold Hot Runner Precision Plastic Injection Mould

Advance Service before sales 1. We can provide comprehensive and professional Suggestions on equipment selection. 2. Energy consumption calculation and investment income analysis can be provided. 3. Provide tailor-made CAD drawings of workshop layout and product optimization suggestions Advantages of tech teams 1.More than 800 sets per year mold making enable us to have rich experience across kinds of industries. 2. Enough and advance equipments for customer product characteristics. 3. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry. Advantages of after-sales team 1. Lifetime free service for the machine. 2. Quick response all day long. 3. Set up domestic service team and international service team. 4. Technicians also master the debugging and maintenance of auxiliary equipment.

Precision Plastic Injection Mould Cold Hot Runner Plastic Injection Mould Plastic Injection Mould Hot Runner Plastic Injection MouldEmail Details