injection mould

-

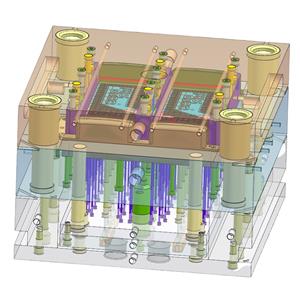

Injection Mould Plastic Products Molding For Homewares

1. Provide high quality custom plastic injection parts and plastic injection molds; 2. Plastic injection mold parts can be different material such as, ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET etc.; 3. Different plastic injection mold parts can pass different certification, such as UL test, V0 fire resistant test, FDA test, REACH test, SGS test and IP65; 4. Can also provide different surface treatment for plastic injection mold, such as Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding; 5. Beside plastic injection mold parts, we also provide printing, welding, assembly and packing service.

Injection Mould Plastic Products Molding Plastic Products Molding for Homewares Molding for Homewares Injection Products MoldingEmail Details -

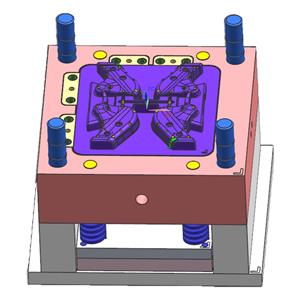

Plastic Fitness Equipment Injection Parts Mould

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. 2. Our workshop area is about 7500 square meters; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;

Plastic Fitness Equipment Mould Plastic Fitness Equipment Injection Mould Plastic Injection Parts Mould Fitness Equipment Injection MouldEmail Details -

Fitness Equipment Plastic Cover Injection Mould

1. Provides service of part design, prototype making, mold design, mold production, mass production and assembly service in house. We are cooperating with many clients all over the world and have a deep understanding of the mold industry, our experience range from simple design to challenging technical parts; 2. Our service also covers in making CNC prototypes, die casting, injection mold with production; And sandblasting, painting, anodizing, electroplating, high polishing and laser etching also can be finished well.

Plastic Cover Injection Mould Plastic Cover Mould Fitness Plastic Cover Injection Mould Fitness Plastic Injection MouldEmail Details -

Custom Plastic Injection Mould For Plastic Products

1. One-stop Solution: Can provide one-stop service from mold design, mold making, machining, surface, injection production, screen printing, spray paint, assembly, packing to shipping; 2. Quality Guarantee: We have a professional team and strict quality management system to control the quality. And experienced engineers, precision machines, CMM and closed-loop QC system; 3. Customer Service: With more than 10 engineers for mold design, programming and project managers. We are using CAD/CAE/CAM software to do the design, analysis & programming.And every client is served by a specialized sales for timely technical support and after-sales service.

Custom Plastic Injection Mould Mould for Plastic Products Custom Mould Custom Mould for Plastic ProductsEmail Details -

Multi Color Plastic Injection Mould Overmolding

1. Professional experience in one-stop solution on tooling and production; 2. Satisfy the precision mold requirement in wide rage industry; 3. Can do from mold design to manufacturing.

Overmolding Plastic Injection Mould Overmolding Multi Color Mould Overmolding Multi Color Injection OvermoldingEmail Details -

Plastic Moulding Medical Injection Mould

1. We can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 2. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 3. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. 4. More than 15years experience for plastic injection mould and plastic injection and developing capability. 5. Enough and many kinds of injection machines to ensure the quantity;

Email Details -

Universal Product Industrial Plastic Injection Mould

For Plastic Injection Mould: 1. High quality raw material to ensure the high quality of the plastic injection mould; 2. Fast delivery, if the sample plastic injection mould, we can finish in 10days; 3. More than 800 mould making experience; 4. Can offer plastic injection making and injection plastic parts, silk screen print and spray paint one stop service. For Plastic Injection Products: 1. Advance injection machine to ensure the quality; 2. Enough and many kinds of injection machines to ensure the quantity; 3. High productivity;

Industrial Plastic Injection Mould Universal Plastic Mould Universal Industrial Plastic Mould Universal Industrial Injection MouldEmail Details -

Precision Injection Molding Plastic Mould

Production capacity: Our factory is working 24 hours and 28 days every month and with more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. Quality control and test: It has many times of quality check for every order, beginning from raw material check to package check. Every production line has at least two QC staff for random check and regular check. Test: manufactory testing machine includes rubber tension tester, rubber vulcanization instrument, durometer, calipers, ageing oven for Density test, Elongation at break, Bonding strength, Pulling force test, twisting force test, Rergarding other test like anti-high/low temperature which will be tested by Third Party Testing Center as customer required.

Injection Molding Plastic Injection Molding Plastic Mould Precision Injection Molding Precision Plastic MouldEmail Details