Plastic Fitness Equipment Injection Parts Mould

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment.

2. Our workshop area is about 7500 square meters;

3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;

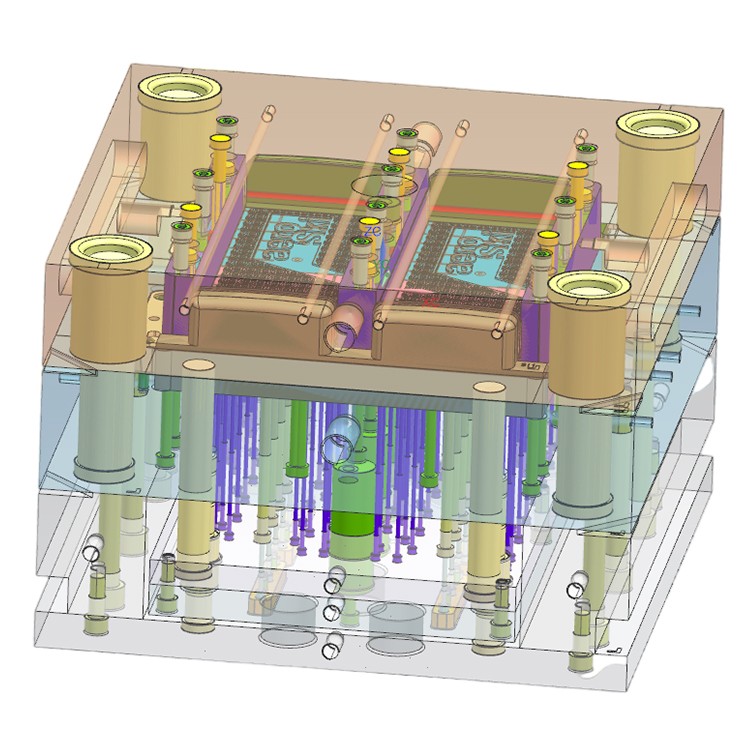

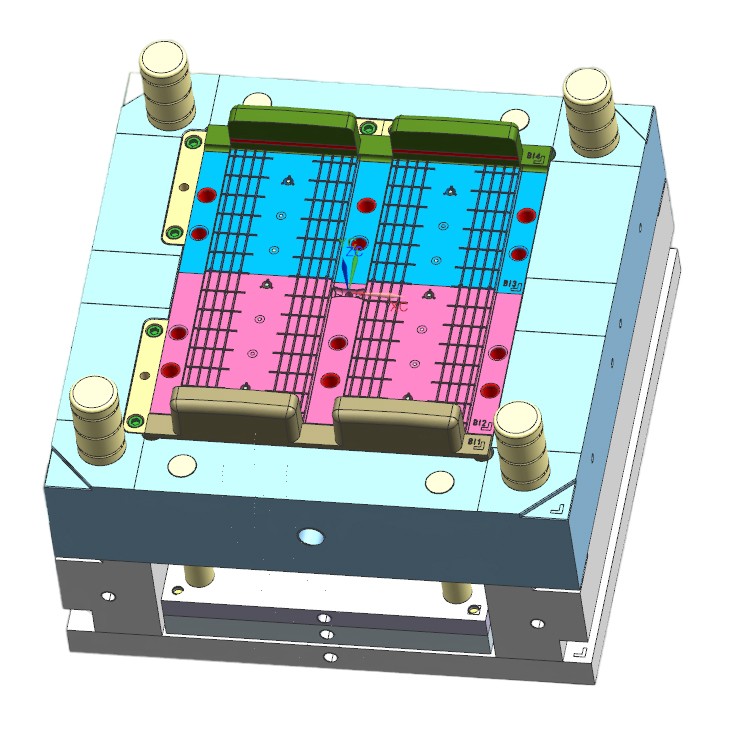

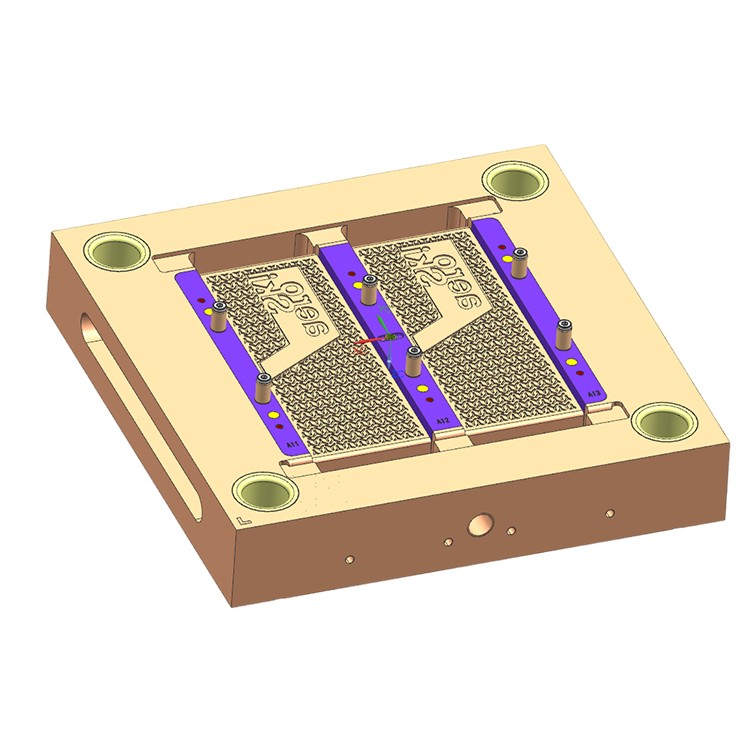

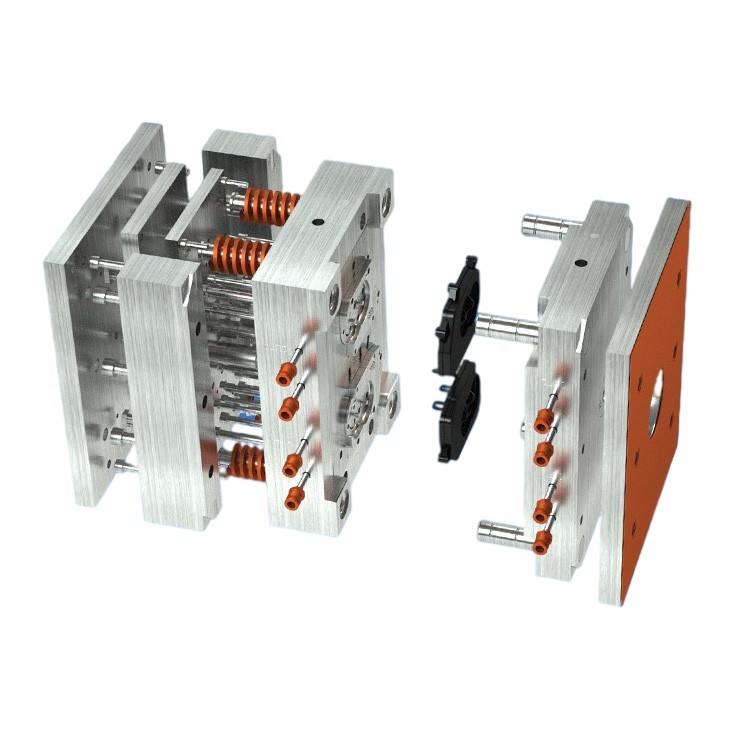

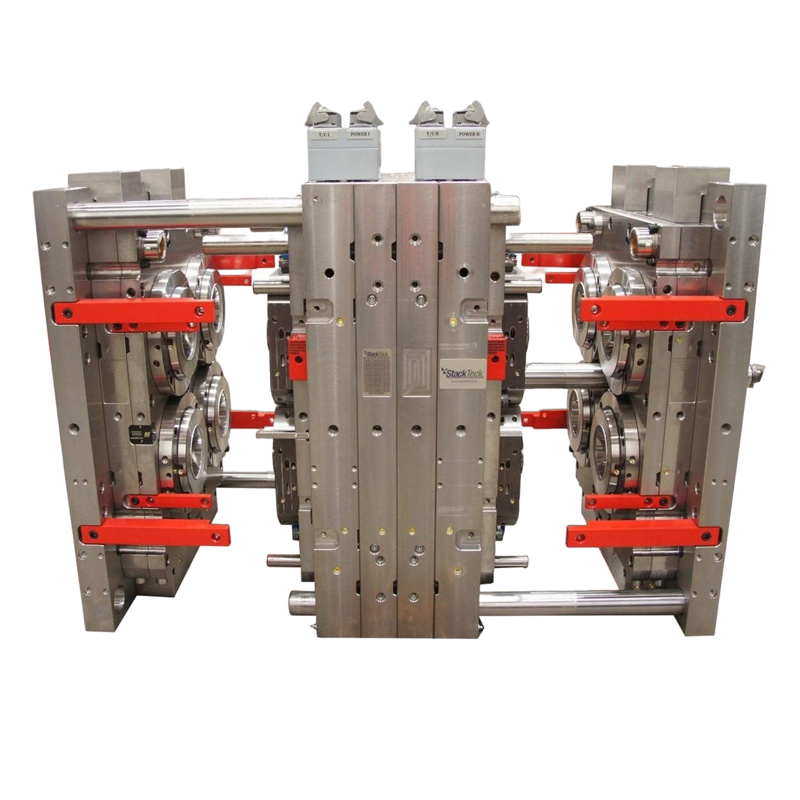

Plastic Fitness Equipment Injection Parts Mould

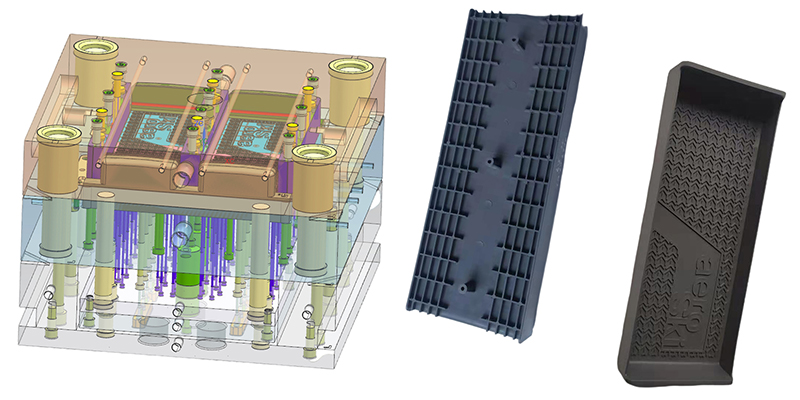

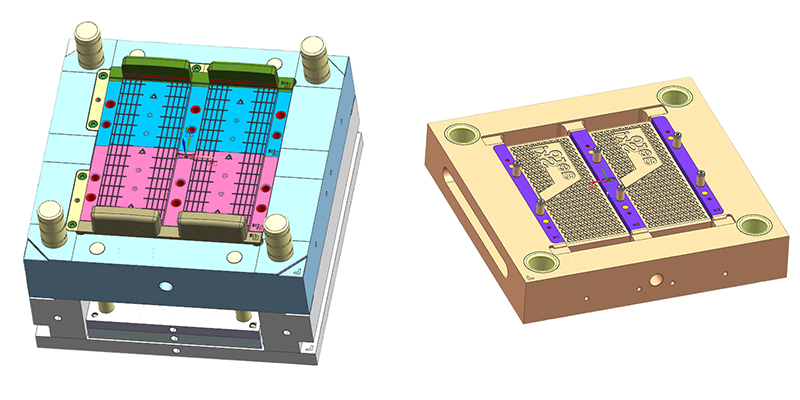

Plastic Fitness Equipment Mould Description:

Product Name | Plastic Fitness Equipment Injection Parts Mould |

Mold Base Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Cavity/Core Steel | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc |

Mold Life | 50K-1.5Million Shots |

Runner System | Hot runner/Cold runner or combined |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 35 TO 650ton Horizontal injection machines, 50 to 160ton Vertical injection machines |

Size | According to your 2D, 3D Drawing(Custom Size) |

Surface Treatmetn | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

Color,Quantity,Unit price,Tooling cost,Tooling size | To be discussed |

Plastic Fitness Equipment Mould and Products Show:

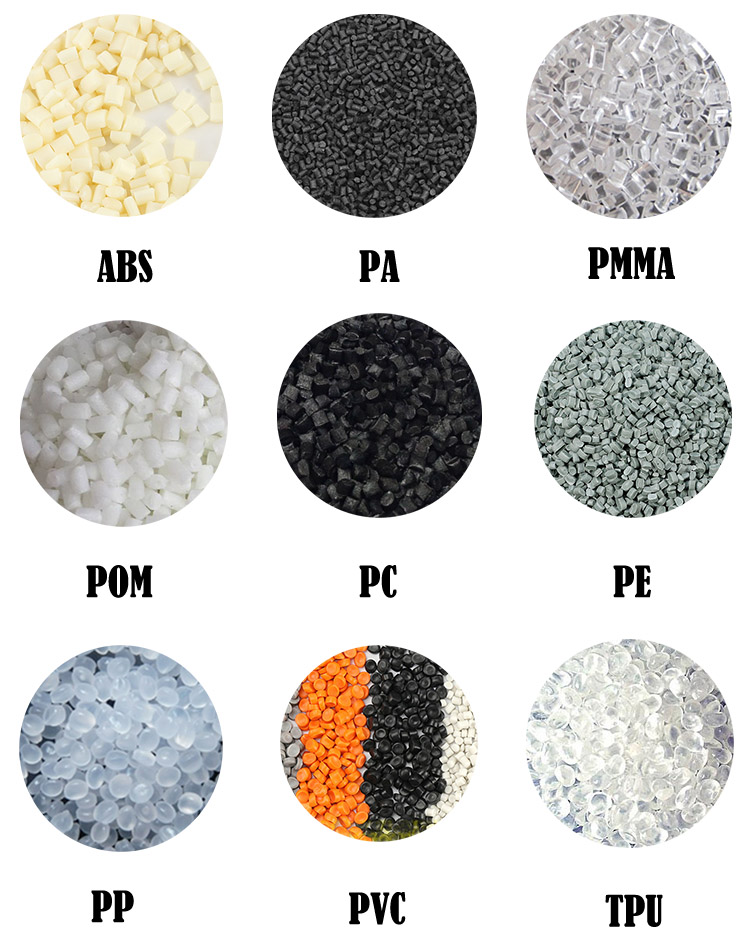

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Packing and Shipping: