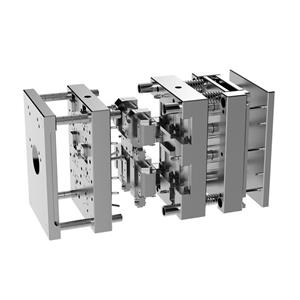

medical mould

-

Hot

Plastic Injection Molding Medical Parts Mould

1. Good experience in mould making since the year of 2002. 3. Machinery core pulling system save cost and increase production efficiency. 4. Perfect core pulling distance within 180mm. 5. Excellent R&D team.(We can offer you 3D mould design with all details within one day.) 6. Efficiency production, we can finish Push-Fit fitting mould of size 110mm in two cavity with in 45days.) 7. Competitive price in save level of mould manufactuers.

Medical Parts Mould Plastic Injection Medical Parts Mould Plastic Medical Parts Mould Plastic Injection Medical MouldEmail Details -

Plastic Moulding Medical Injection Mould

1. We can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 2. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 3. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. 4. More than 15years experience for plastic injection mould and plastic injection and developing capability. 5. Enough and many kinds of injection machines to ensure the quantity;

Email Details