Plastic Injection Molding Medical Parts Mould

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. Good experience in mould making since the year of 2002.

3. Machinery core pulling system save cost and increase production efficiency.

4. Perfect core pulling distance within 180mm.

5. Excellent R&D team.(We can offer you 3D mould design with all details within one day.)

6. Efficiency production, we can finish Push-Fit fitting mould of size 110mm in two cavity with in 45days.)

7. Competitive price in save level of mould manufactuers.

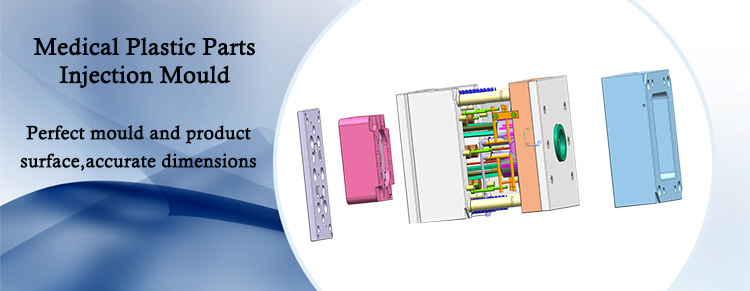

Plastic Injection Molding Medical Parts Mould

Plastic Medical Mould Specification:

Mould Base | DME, SD, LKM, HASCO and so on |

Mold Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Mold Accuracy | +/-0.001mm |

Mold Life | 50K-1.5Million Shots |

Runner System | Hot runner/Cold runner or combined |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 35 TO 650ton Horizontal injection machines, 50 to 160ton Vertical injection machines |

Plasitc Material | PA6, PA66, ASA, POM, PPS, ABS, ABS+GF, ABS/PC, POM(Derlin), PP, PE, PC, PMMA(Acrylic), PVC, PEI, PBT, PTF etc. |

Surface Treatmetn | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

Certificates | ISO 9001 |

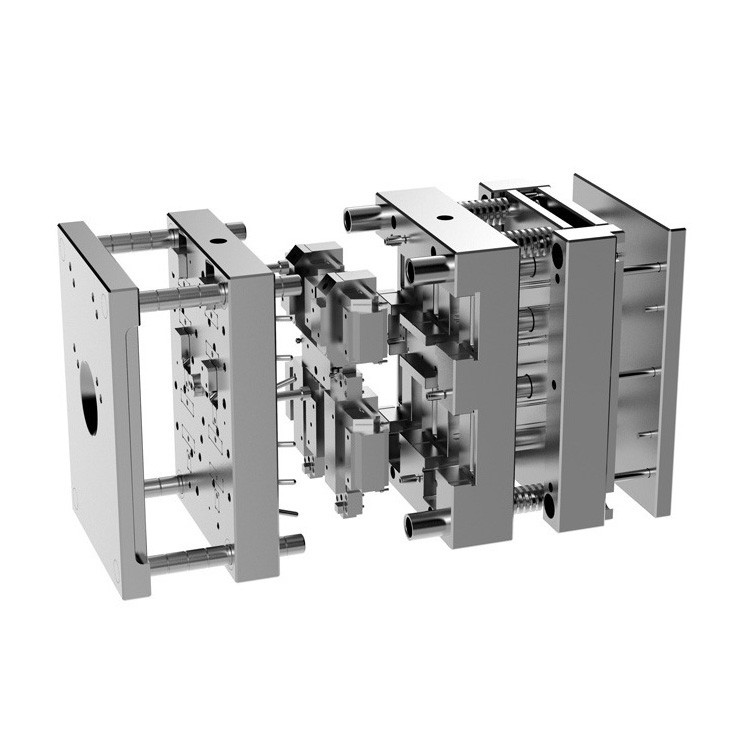

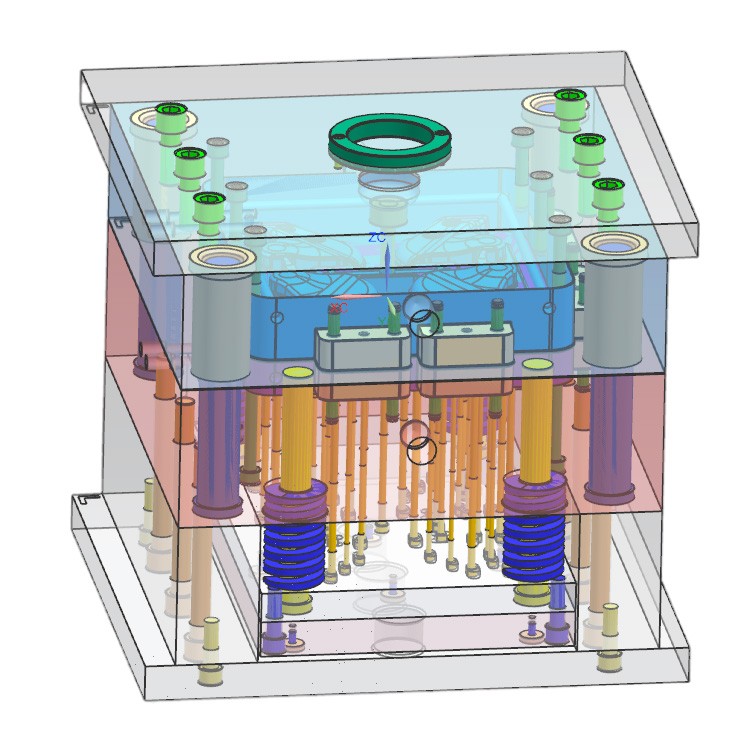

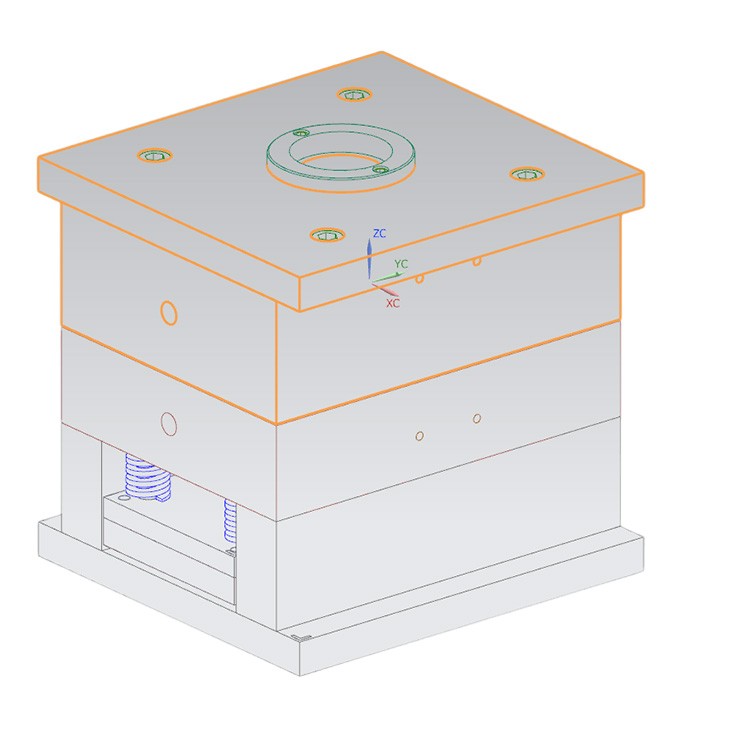

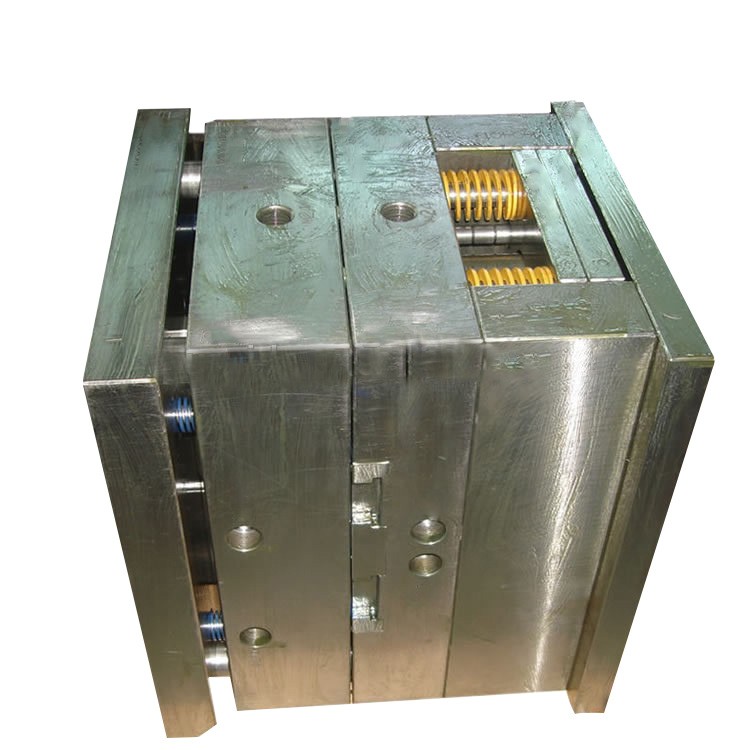

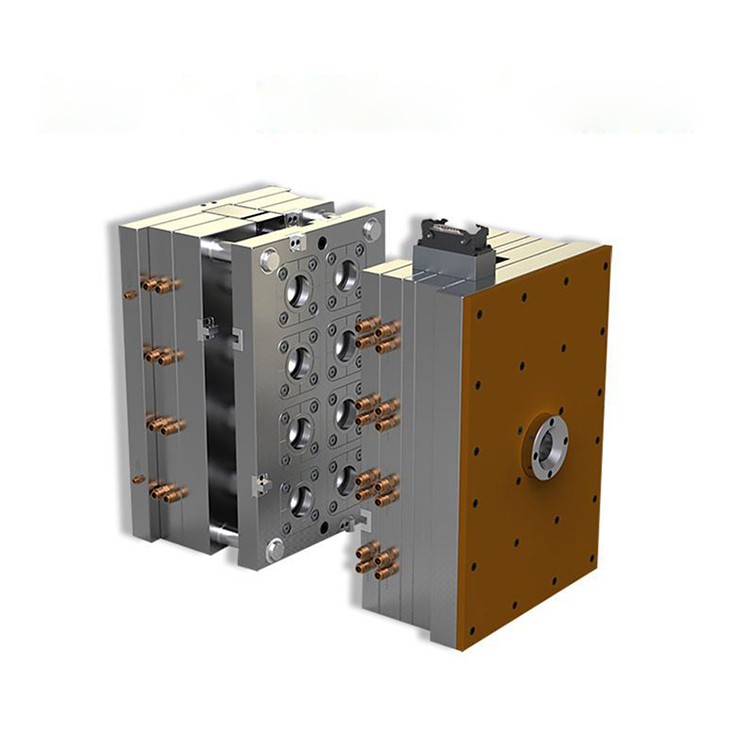

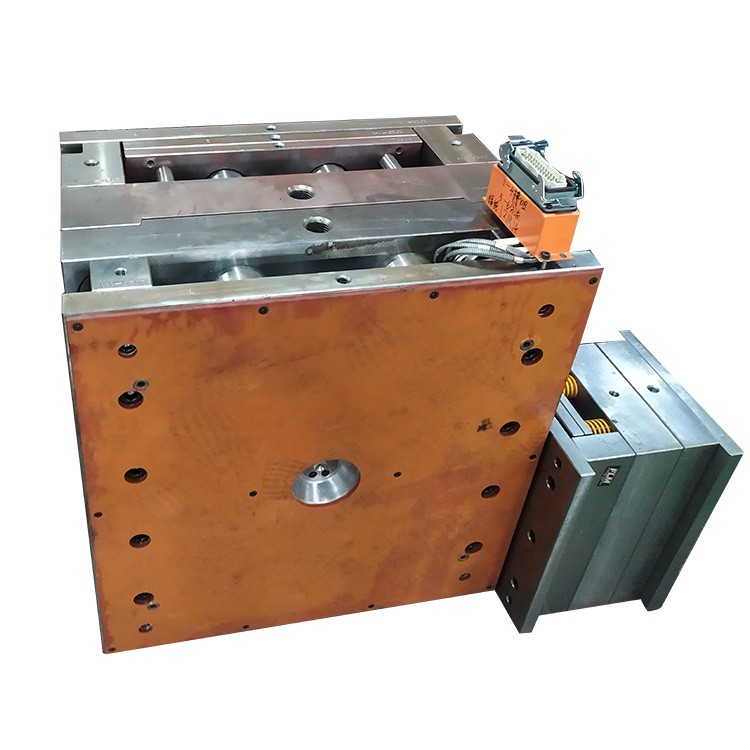

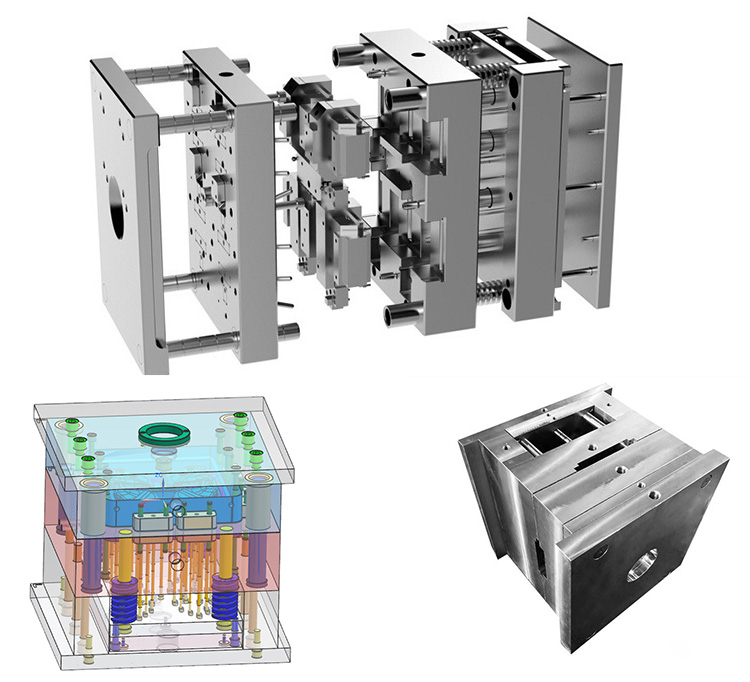

Plastic Medical Mould Show:

Plastic Medical Mould Manufacturer Information:

Xiamen Jinen & Jinjiekun provide custom molds for customers all over the world, such as USA, UK, Canada, Indian, Europe, Asia and South America etc.

We have been engaged in the mold industry since 2001. Our products involve medical, automotive, sports, hunting, electronics, containers, packaging and so on.

Our Service:

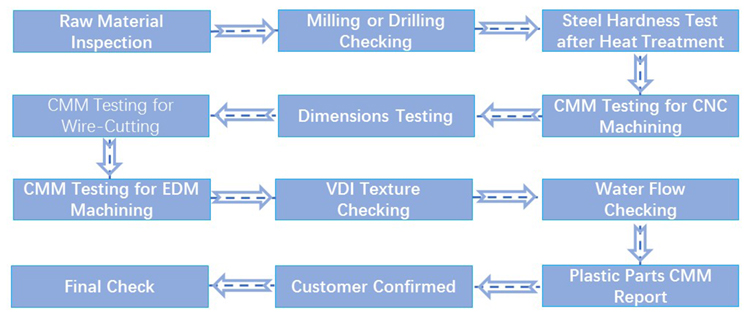

Quality Control Process:

Packaging and Delivery:

FAQ:

Q1: I have a good idea but don't know how to do with it, can you help me?

Yes, Our engineer will make a sketch for you to check. and also a 3D prototype if you let us know your ideal.

printing, CNC and laser cutting to see if there is any detail need to be improved.

Q2: Do you accept OEM part?

Yes, you just offer us your 3D drawings. If you do not hvae the drawings but have samples, then send us the samples, our engineer can make the drawing.

Q3: Can you do assembly and customized package for us?

Off course, we can offer you one-stop service, from mold design, mold tooling, injection production, screen printing, spray paint, assembly to packing.

Q4: When can I get the sample after payment for mold?

It will take around 30 days for mold making. And we will test the mold to make the samples and send to you to check.

Q5: What is the minimum & maximum unit weight and size your machines can produce?

Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.