injection molding plastic

-

Injection Molding Custom Plastic Parts

Plastic Injection Products Feature and Application: 1. Efficiency production and automotive operation; 2. Shape can be from simple to complex, the size can be from large to small and the product size is accurate; 3. It is used in the forming and processing fields of mass production and products with complex shapes. The application we involve house appliance, fitness equipment, electronics, industrial, auto parts, bathroom, medical, over molding and so on.

Custom Plastic Parts Injection Molding Plastic Parts Injection Molding Custom Plastic Parts Injection Custom Plastic PartsEmail Details -

Double Injection Molding Plastic Overmolding

1. Good experience in mould making since 2005. 2. Machinery core pulling system save cost and increase production efficiency. 3 .Perfect core pulling distance within 180mm. 4. Excellent R&D team.(We can offer you 3D mould design with all details within one day.) 5. Efficiency production, we can finish Push-Fit fitting mould of size 110mm in two cavity within 45days.) 6. We have our own tooling shop, equipped with advanced machines for plastic injection mould and the plastic injection products.

Plastic Overmolding Molding Plastic Overmolding Double Injection Overmolding Injection Molding Plastic OvermoldingEmail Details -

Homeware Injection Molding Plastic Mould

1) We are a professional OEM&ODM plastic injection mold manufacturer; 2) We have a team with experienced engineers and quality control team as our strong backing; 3) High quality, competitive price, quick response; 4) Professional technical support; 5) Quick response; 6) A strict quality control process; 7) High-cost performance; 8) More than 15 years experience in plastic injection mold and plastic injection; 9) ISO/ERP system guarantee.

Homeware Injection Molding Homeware Molding Homeware Injection Molding Plastic Mould Homeware Injection Plastic MouldEmail Details -

Precision Injection Molding Plastic Products

We have a professional engineers design team with more than people and can use CAD, Pro-E, UG, Solidworks etc. to ensure all kinds of design.Before the project started: 1. If you have 3D STEP/IGES/X_T drawing or 2D drawing, please send it to us before quotation, then we will do DFM and mould design for you. 2. If you only have samples please provide us the samples, we can design 3D drawing for you and quotation. We have enough and advance equipment and machines, such as high CNC and other equipment for plastic mold making, 60 to 950T plastic injection machines for the plastic mold, assembly line for spray print and other machine for us to provide the one-stop service.

Precision Plastic Products Injection Molding Plastic Products Injection Plastic Products Precision Injection ProductsEmail Details -

OEM Injection Molding Plastic Products

We have introduced many international advanced equipment and machines at home and abroad, including complete CAD/CAE/CAM system, computer three-dimensional measuring instrument, CNC computer controlled EDM center and plastic injection machines from 60T to 950T and the other machines for plastic mold making and plastic injection to ensure us can design and manufacture various mold products according to user requirements. We also have rich experience in plastic mold and plastic injection since 2005. Besides, we also have the advance management system, strict quantity control process and the professional team for sales, R&D, production and after sales service.

OEM Plastic Products OEM Injection Plastic Products OEM Injection Molding Plastic Products OEM Injection ProductsEmail Details -

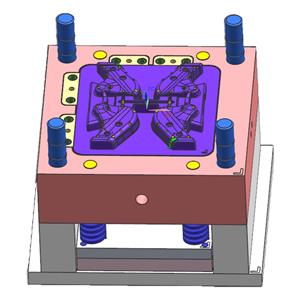

Precision Injection Molding Plastic Mould

Production capacity: Our factory is working 24 hours and 28 days every month and with more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. Quality control and test: It has many times of quality check for every order, beginning from raw material check to package check. Every production line has at least two QC staff for random check and regular check. Test: manufactory testing machine includes rubber tension tester, rubber vulcanization instrument, durometer, calipers, ageing oven for Density test, Elongation at break, Bonding strength, Pulling force test, twisting force test, Rergarding other test like anti-high/low temperature which will be tested by Third Party Testing Center as customer required.

Injection Molding Plastic Injection Molding Plastic Mould Precision Injection Molding Precision Plastic MouldEmail Details -

Injection Molding Components Plastic Cover

1. Custom or standard plastic injection mould or plastic injection products. 2. Finishing: high polish, bevelling or common matte surface finishing. 3. Materials including PVC, ABS, PC, PP, PE, EPS, POM, PA, PET, ASA, etc. available. 4. Single extrusion, coextrusion and triextrusion available. 5. Rigid material, soft material, rigid material+flexible material co-extrusion. 6. Product range: plastic frame, seal and gasket for refrigrator, freezer, cold chain and kitchen cabinet, vending machine and air conditioner, and drainage tube, round tube, etc. 7. Features: UV/weather resistant, thermal resistant, durable, anti-noise, good tightness, waterproof, dustproof, sound proof, etc. 8. RoHS and REACH compliance

Plastic Cover Injection Plastic Cover Injection Molding Plastic Cover Injection Components Plastic CoverEmail Details