Injection Molding Components Plastic Cover

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. Custom or standard plastic injection mould or plastic injection products.

2. Finishing: high polish, bevelling or common matte surface finishing.

3. Materials including PVC, ABS, PC, PP, PE, EPS, POM, PA, PET, ASA, etc. available.

4. Single extrusion, coextrusion and triextrusion available.

5. Rigid material, soft material, rigid material+flexible material co-extrusion.

6. Product range: plastic frame, seal and gasket for refrigrator, freezer, cold chain and kitchen cabinet, vending machine and air conditioner, and drainage tube, round tube, etc.

7. Features: UV/weather resistant, thermal resistant, durable, anti-noise, good tightness, waterproof, dustproof, sound proof, etc.

8. RoHS and REACH compliance

Injection Molding Components Plastic Cover

Plastic Injection Products Specification:

Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc. (Hardness 35~55HRC) |

Mould base | Standard mould base, LKM, HASCO etc. |

Cavity | Single/multi |

Runner | Hot/cold |

Ejection system | Motor/hydraulic cylinder/stripping plate/angle pin, etc. |

Cooling system | In core baffle and in cavity plate chain drilling type cooling |

Design software | UG, PROE, CAD, CAXA etc. |

Plastic material | ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc. |

Surface treatment | Polish, texture, sand blasting, chrome plating |

Mould life | 300,000-1,000,000 shots |

Plastic Injection Products Picture:

Plastic Injection Products Feature and Application:

1. Efficiency production and automotive operation;

2. Shape can be from simple to complex, the size can be from large to small and the product size is accurate;

3. It is used in the forming and processing fields of mass production and products with complex shapes.

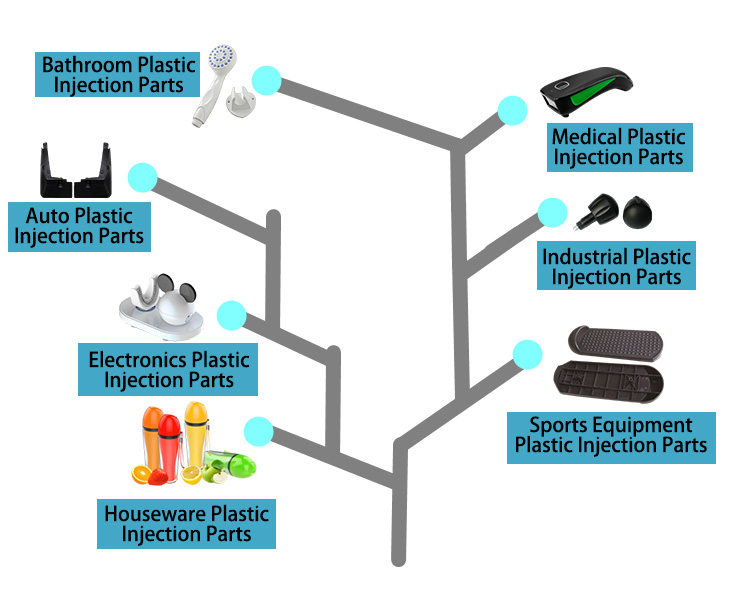

The moulds we make involves house appliance, fitness equipment, electronics, industrial, auto parts, bathroom, medical, over molding and so on.

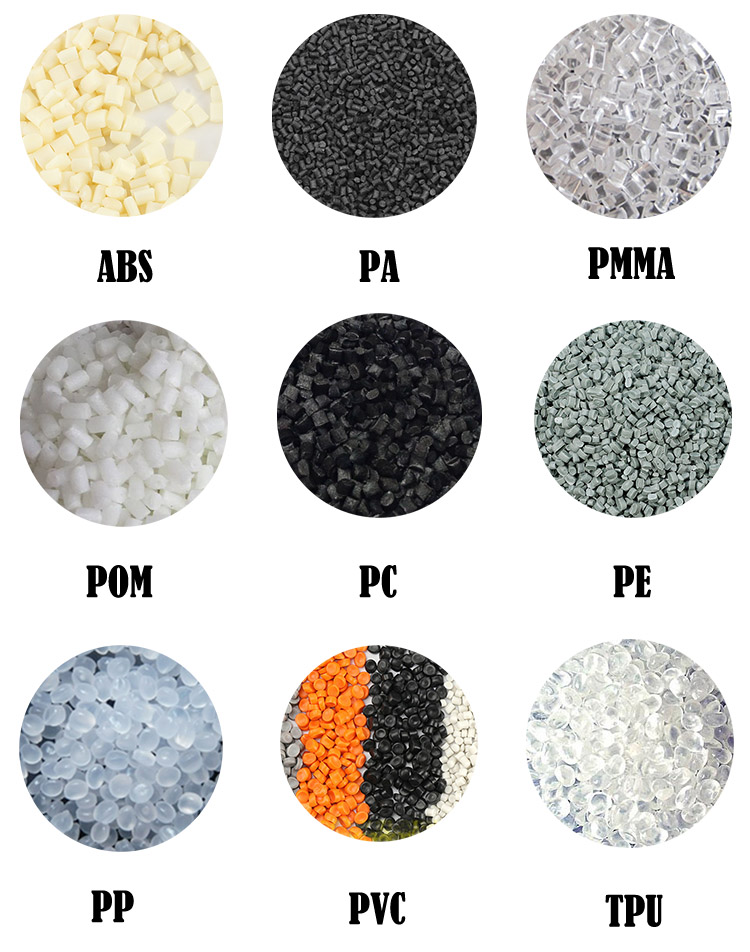

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Plastic Injection Products Manufacturer Information:

We are a professional manufacturer of Plastic injection mould and plastic products express in plastic parts of sport equipment and plastic household products. Now we are one of the important manufacturers in sport equipment industry and plastic household industry. We also produce and sales plastic household products and plastic electronic products.

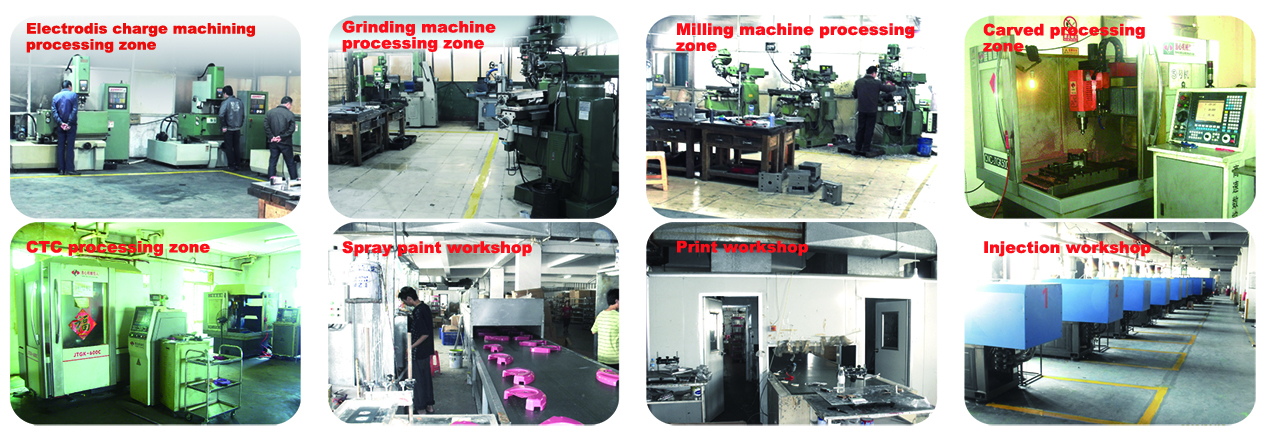

We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, assembly work, pad printing, silk screen print, paint, ultrasonic welding and packaging services.

With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

Our Plastic Parts Case Show:

Payment and Shipping:

We accept many kinds of the payment, the details as the following:

1. For the samples, we can accept PayPal, West Union and Bank Transfer as the payment, and will ship the samples by air express, such as the DHL, UPS and FEDEX.

2. For the bulk order, we can suggest the bank transfer as the payment method with the 30% deposit, we will ship out the goods according to the choice from the customers for shipping.

3. We can ensure the shipping is fast and efficient.