plastic injection mould

-

Plastic Injection Mould For Treadmill Parts

1. Rich Eexperience: with more than 15 years plastic injection mould industry experience 2. Customed Accepted: OEM&ODM projects are highly welcomed, we have strong R&D team, can help modify drawings 3. Strict quality control: 1). Materials inspection by IQC; 2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production; 3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects; 4). FQC will check the products before sending to the warehouse; 5). 100% inspected by OQC before shipping out.

Plastic Mould for Treadmill Parts Injection Mould for Treadmill Parts Mould for Treadmill Parts Plastic Injection Treadmill PartsEmail Details -

Customzied Electronics Plastic Injection Mould

For Plastic Injection Mould: 1. High quality raw material to ensure the high quality of the plastic injection mould; 2. Fast delivery, if the sample plastic injection mould, we can finish in 10days; 3. More than 800 mould making experience; For Plastic Injection Products: With more than 15years experience and more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment to ensure the quality and quantity;

Electronics Plastic Injection Mould Customzied Plastic Mould Customzied Plastic Injection Mould Customzied Electronics MouldEmail Details -

Fitness Equipment Plastic Parts Injection Moulding

Plastic Injection Mould and Services: 1. Products Designing & Manufacturing. 2. Rapid Prototyping 3. Plastic Moulds Designing & Manufacturing. 4. Plastic Injection Molding 5. Product Treatment & Product Assembling 6. OEM/ODM is welcomed.

Parts Injection Moulding Fitness Equipment Injection Moulding Fitness Injection Moulding Fitness Plastic Injection MouldingEmail Details -

Hot

Plastic Injection Mould for Bathroom Products

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. 2. Our workshop area is about 7500 square meters; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;

Email Details -

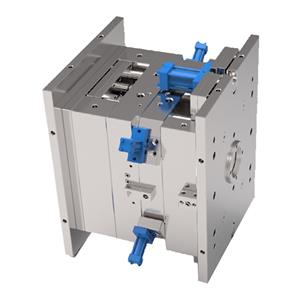

Cold Hot Runner Precision Plastic Injection Mould

Advance Service before sales 1. We can provide comprehensive and professional Suggestions on equipment selection. 2. Energy consumption calculation and investment income analysis can be provided. 3. Provide tailor-made CAD drawings of workshop layout and product optimization suggestions Advantages of tech teams 1.More than 800 sets per year mold making enable us to have rich experience across kinds of industries. 2. Enough and advance equipments for customer product characteristics. 3. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry. Advantages of after-sales team 1. Lifetime free service for the machine. 2. Quick response all day long. 3. Set up domestic service team and international service team. 4. Technicians also master the debugging and maintenance of auxiliary equipment.

Precision Plastic Injection Mould Cold Hot Runner Plastic Injection Mould Plastic Injection Mould Hot Runner Plastic Injection MouldEmail Details -

Beach Chair Mould

We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint and Packaging Services. 1. Began OEM & ODM Plastic service since 2007 and with more than 800 molds making experience; 2. Our company has a professional, complete production equipment, Injection Machines from 60T to 950T and with high precision and top quality; 3. Have a professional team and strict quality management system to ensure the quality; 4. Our workshop area is about 7500 square meters;

Households Plastic Injection Mould Custom Households Mould Households Plastic Mould Custom Households Plastic MouldEmail Details -

Hot

ABS Plastic Injection Mould

1. Good mechanical and thermal properties, high hardness, easy to plate metal on the surface. 2. Fatigue resistance and stress cracking resistance, high impact strength. 3. Resistant to chemical corrosion such as acid and alkali. 4. Low price. 5. Easy to process and modify. 6. Application classification of ABS plastics: general structural parts, machine covers, covers, instrument cases, hand drill cases, fan impellers, radio, telephone and TV cases, some electrical parts, auto parts, machinery and conventional weapon parts.

Email Details -

Bathroom Parts Plastic Injection Moulding

1. Have experience for mould 2. 3D Drawing service from plastic to plastic injection moulding tool design 3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts. 4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts. 5. We have professional plastic injection mold tooling designer and plastic part producing line. 6. Plastic Injection Mould OEM & ODM Services

Injection Moulding Bathroom Plastic Injection Moulding Bathroom Parts Plastic Injection Moulding Bathroom Parts Plastic MouldingEmail Details -

Plastic Injection Moulding Industrial Mould

1.We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. 2.We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts. 4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts. 5. We have professional plastic injection mold tooling designer and plastic part producing line. 6. Plastic Injection Mould OEM & ODM Services

Plastic Injection Moulding Plastic Injection Industrial Mould Plastic Moulding Industrial Mould Injection Moulding Industrial MouldEmail Details