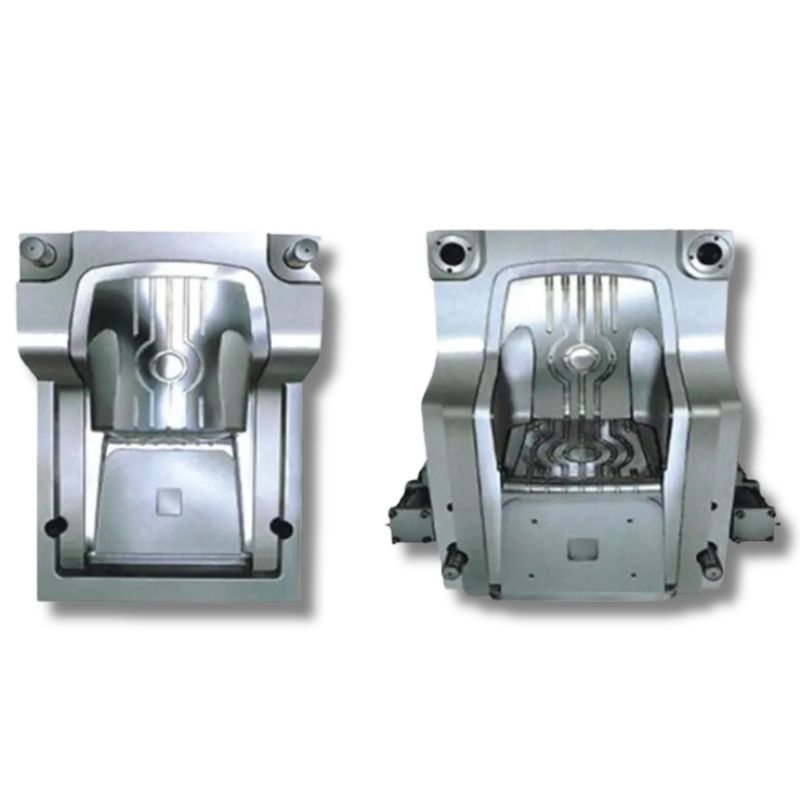

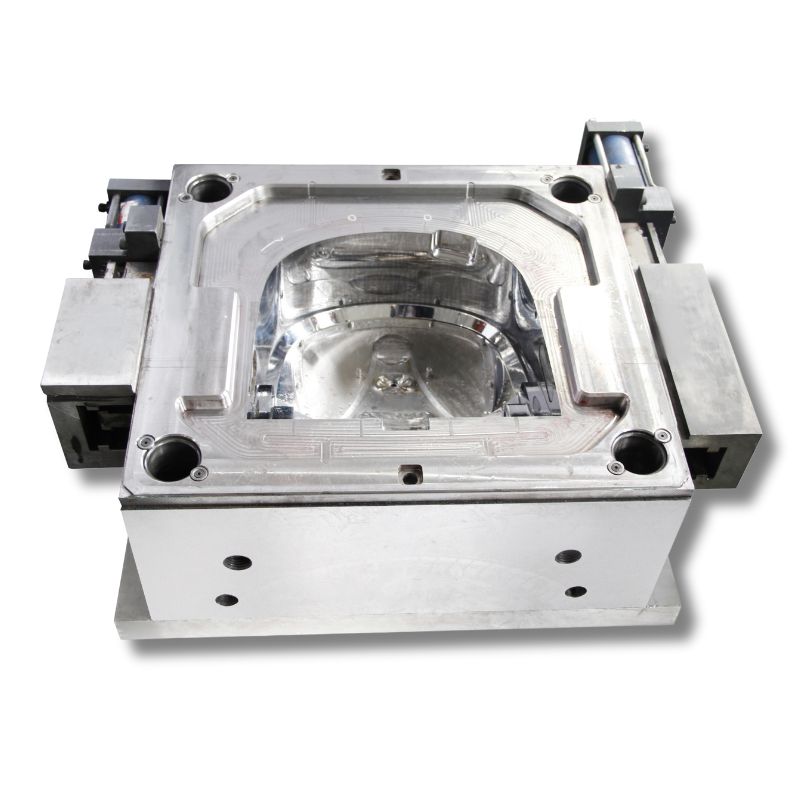

ABS Plastic Injection Mould

- KCN

- Xiamen, Fujian, China

- 30 days

- 50 Sets Per Month

1. Good mechanical and thermal properties, high hardness, easy to plate metal on the surface.

2. Fatigue resistance and stress cracking resistance, high impact strength.

3. Resistant to chemical corrosion such as acid and alkali.

4. Low price.

5. Easy to process and modify.

6. Application classification of ABS plastics: general structural parts, machine covers, covers, instrument cases, hand drill cases, fan impellers, radio, telephone and TV cases, some electrical parts, auto parts, machinery and conventional weapon parts.

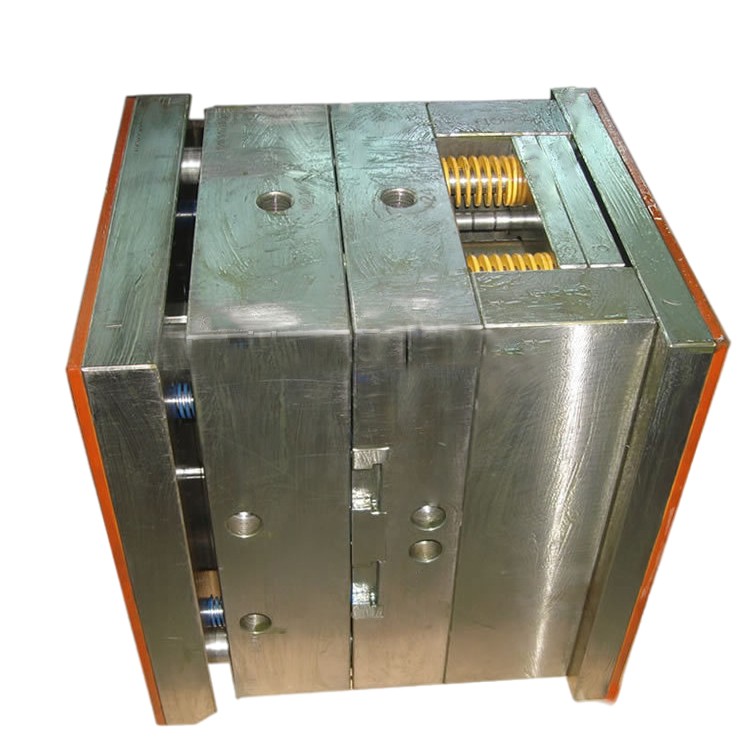

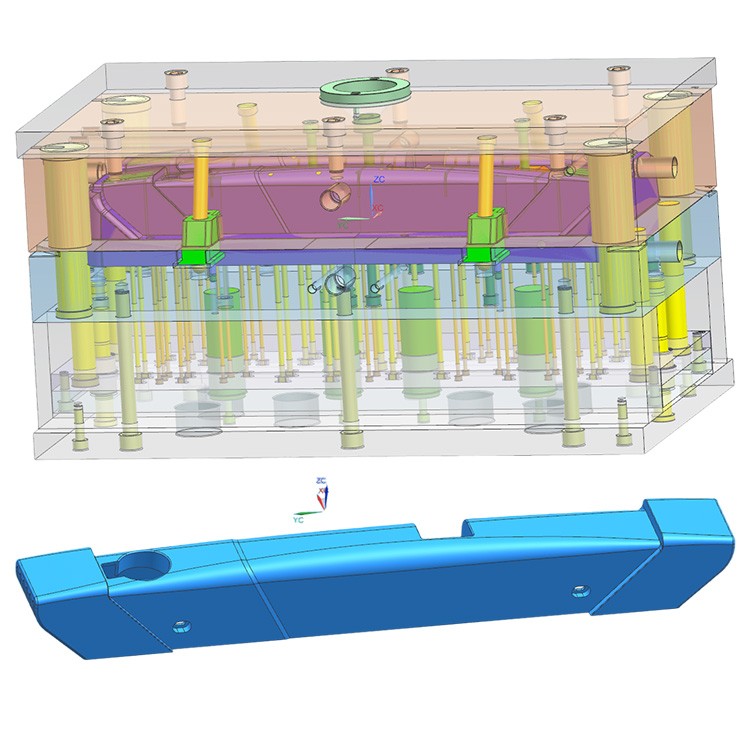

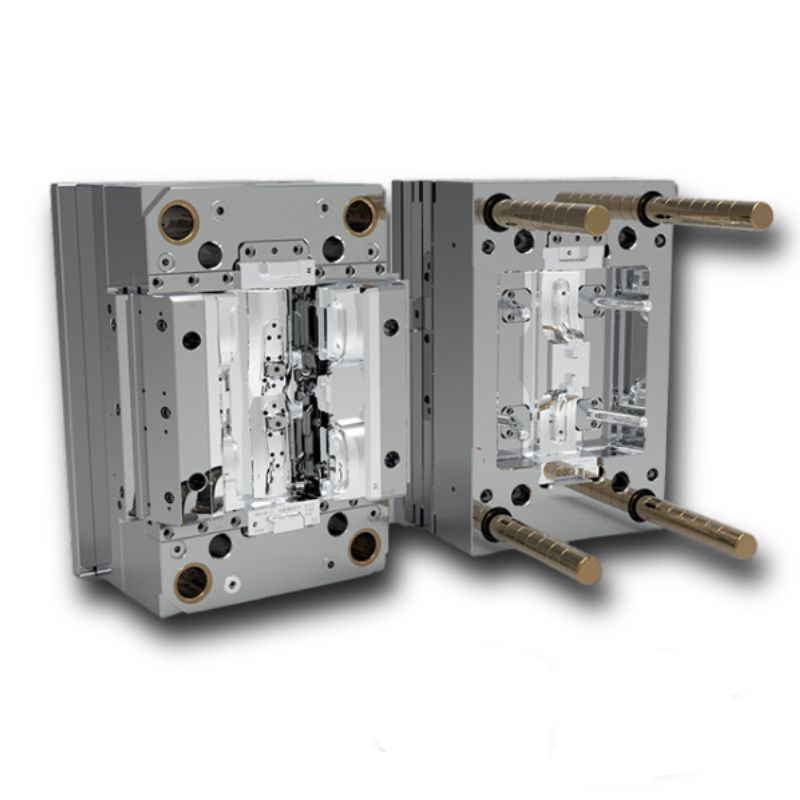

ABS Plastic Injection Mould Specification:

| Mould material | P20, H13, 718, 2738, NAK80, S136, SKD61 etc. | Mould base | Standard mould base, LKM, HASCO etc. |

| Cavity | Single/Multi | Runner | Hot/Cold |

| Ejection system | Motor/hydraulic cylinder/stripping plate/angle pin, etc. | Cooling system | In core baffle and in cavity plate chain drilling type cooling |

| Design software | UG, PROE, CAD, CAXA etc | Plastic material | ABS,PC/ABS |

| Surface treatment | Polish, texture, sand blasting, chrome plating | Product Name | ABS Plastic Injection Mould |

ABS Plastic Injection Mould Feature and Application:

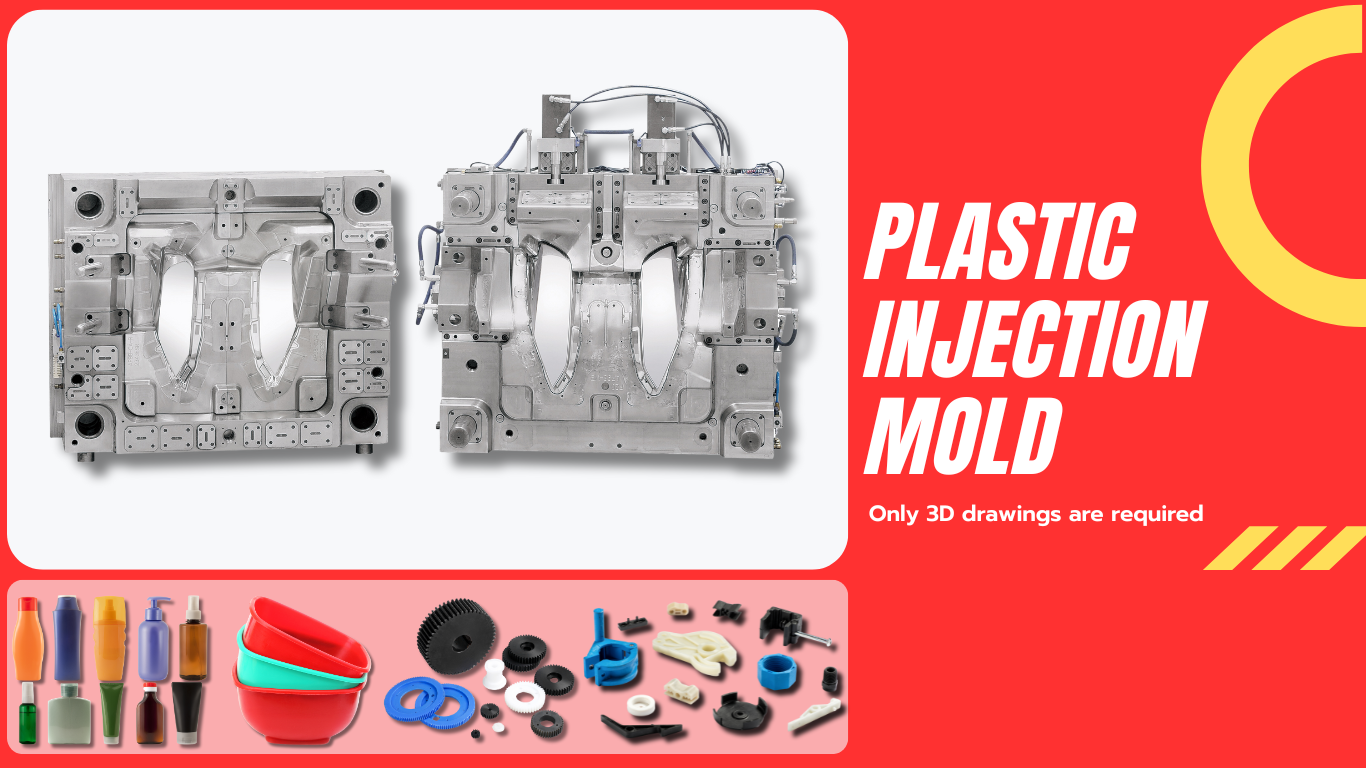

ABS injection molds are widely used in many fields, including machinery, electrical, textile, automobile, aircraft, shipbuilding industry and chemical industry. ABS plastic is favored because of its easy availability of raw materials, good comprehensive performance and low price. This material is tough, hard and rigid, and is suitable for making general mechanical parts, wear-resistant parts, transmission parts and telecommunications parts12. ABS plastic molds have become the cornerstone of shaping a colorful world due to their excellent comprehensive performance and wide application fields. They are particularly suitable for home appliances, automobiles and other industries due to their excellent impact resistance, scratch resistance and weather resistance. With the promotion of environmental protection and sustainable development, the industry is reducing environmental impact and improving sustainability3. In addition, ABS engineering plastics, namely PC+ABS engineering plastic alloys, have the excellent heat and weather resistance, dimensional stability and impact resistance of PC resins, and also have the excellent processing fluidity of ABS resins. This material is suitable for thin-walled and complex-shaped products, and can maintain its excellent performance and the moldability of materials composed of plastic and an ester. Although the biggest disadvantage of ABS engineering plastics is its heavy weight and poor thermal conductivity, its molding temperature range is 240-265 degrees, which ensures stability during processing and product quality4.

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Others Plastic Injection Moulds

ABS Injection Mould

Handle Mould

Backrest Chair Mould

Squat Basin Mould