custom injection plastic

-

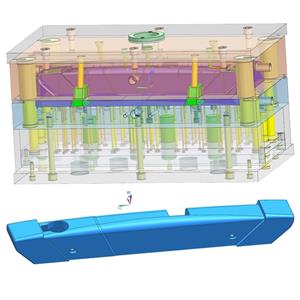

Custom Injection Moulding Plastic Mould

1. Design Service: With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers. 2. Guaranteed delivery: (1) Have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. (2) Our workshop area is about 7500 square meters; (3) Provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 3. Strict quality management system: (1) Material inspection--Check the material surface and roughly dimension. (2) Production first inspection--To ensure the critical dimension in mass production. (3) Sampling inspection--Check the quality before sending to the warehouse. (4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

Email Details -

High Precision Custom Injection Plastic Parts

1.Product engineering, development, consultation and the latest in manufacturing simulation software. 2. A strong dedicated workforce committed to promoting and customer service. 3. Collaboration during the mold design process between our customers, management, and our employees to implement the best possible concept. 4. Our unique capacity to create solutions that replace expensive, fabricated steel products. 5. Provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

Injection Plastic Precision Injection Plastic Custom Injection Plastic Precision Custom Injection PartsEmail Details -

Custom Made ABS Injection Plastic Parts

Plastic mold and plastic injection services are including: 1. Plastic product and plastic injection mold design and development, both ODM and OEM; 2. Scanning data: Get 3D drawing if you only offer the sample for plastic injection mold making; 3. Drawing re-construction; 4. Prototype making; 5. Tooling/Mold setup and trial shot; 6. Injection molding for the plastic parts. 7. Mass production

Injection Plastic Parts ABS Injection Plastic Parts Custom Injection Plastic Parts ABS Injection PartsEmail Details