mold

-

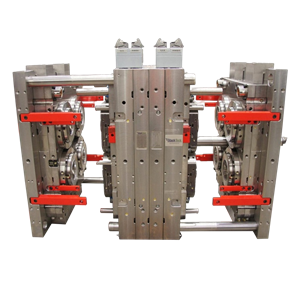

Plastic Electronics Mold For Interphone Injection Case

Professional experience in one-stop solution on tooling and production; Satisfy the precision mold requirement in wide rage industry; Can do from mold design to manufacturing. 1. We have our own tooling shop, equipped with advanced machines for plastic injection mould and the plastic injection products. 2. We also have their own injection shop, to run the mold test & mass production for customers. 3. We have more than 800 mould making experience for plastic injection mould and more than 15years experience for plastic injection. 4. We have 20 precision production equipment which reach the international advanced level and the experienced technician. 5. ISO 9001 Certified for all of our plastic injection mould and plastic injection products and our factory;

Plastic Electronics Mold Electronics Mold Mold for Interphone Injection Case Mold for Injection CaseEmail Details -

Hot

Fitness Equipment Mould Plastic Injection Molding

1. We can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 2. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 3. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Email Details -

Hot

Precision Plastic Injection Households Mold

1. Good experience in mould making since the year of 2008. 2. Machinery core pulling system save cost and increase production efficiency. 3. Perfect core pulling distance within 180mm. 4. Excellent R&D team.(We can offer you 3D mould design with all details within one day.) 5 .Efficiency production, we can finish Push-Fit fitting mould of size 110mm in two cavity with in 45days.) 6. Competitive price in save level of mould manufactuers.

Injection Households Mold Plastic Injection Households Mold Precision Households Mold Precision Plastic Households MoldEmail Details -

Custom Plastic Products Molding Injection Mould

Provide high quality custom plastic injection molded parts; Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET etc.; Different injection molded parts can pass different certification such as UL test, V0 fire resistant test, FDA test, REACH test, SGS test and IP65; Provide different surface treatment for injection molded parts. Commonly use surface treatment for injection molded parts as: Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI; Besides making injection molded parts, we also provide printing, welding, assembly and packing service;

Email Details -

Mini Elliptical Machine Molding

Customized mini elliptical machine, OEM/ODM appearance logo, one-stop plastic molding service.

Email Details -

Smart Home WIFI Shell Molding

Smart home WiFi is an innovative technology product that integrates wireless network connection, intelligent control, and appearance design to provide users with a convenient, efficient, and beautiful smart home experience. KCN Plastic Molding provides OEM and customized shell molding for many smart home brands. It uses ABS injection molding to increase the beauty and durability. The color and logo can be customized. If you have commercial needs, please contact us. One-stop solution and product molding.

Email Details -

Car Lampshade Molding

1. High-strength material: high-strength materials are used to improve the impact resistance and deformation resistance of the lampshade. 2. Weather resistance: After special treatment, it has good weather resistance and can adapt to various harsh climatic conditions. 3. High light transmittance: unique design, improve light transmittance, and ensure lighting effect. 4. Personalized customization: According to customer needs, personalized customization services can be provided to meet the needs of different models and appearance designs.

Email Details -

Industrial Parts Box Molding

Product specifications: customized parts Color: customized pieces Minimum order quantity: 100 pieces for customization Product name: Precision plastic parts Product Category: Plastic Parts Material:ABS Manufacturer (Origin): Xiamen, China Implement quality standards: ISO9001

Email Details -

High-Precision Plastic Parts Molding

Main business: 1. Customized injection mold 2.Injection molding services 3. Production of fitness equipment parts 4. Assembly and packaging services Focus on providing customized manufacturing services based on design drawings or samples. Tip: 1. Support OEM/ODM customization! Welcome to contact us! 2. There are special offers now. You can get them by sending an inquiry 3. Support samples, if you need samples to send inquiries, please contact us

injection mold Injection molding services Production of fitness equipment parts Assembly and packaging servicesEmail Details