plastic mold

-

Plastic Injection Molding Components

1. We are a specialized in plastic injection mold and plastic parts molding. We have produced more than 600 sets of molds per year and have been molding millions of plastic parts. The mold and plastic parts we made are widely applying in electronic, household, automotive, fitness equipment and medical industry. 2. Excellent R&D team: with more than 10 engineers for plastic product and plastic injection mold design, programming, project managers. we are using CAD/CAE/CAM software to do the design; 3. Efficiency production: it depends on the products' size and complexity. Normally, the lead time is 15-25 days.

Email Details -

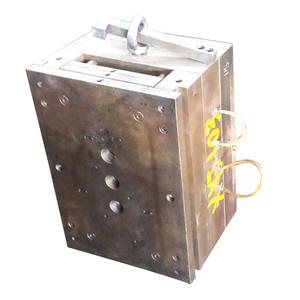

Fitness Equipment Spare Parts Plastic Injection Mold

1. Start from part design analysis; 2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making; 3. If product is complex, moldflow report will be present as well; 4. In house mold making shop ensure you mold quality under well control; 5. Normally it takes 20-40 days to make mold, precise time depends on part design; 6. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 7. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 8. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Spare Parts Plastic Mold Spare Parts Injection Mold Spare Parts Plastic Injection Mold Fitness Equipment Spare Parts MoldEmail Details -

Custom Plastic Injection Molding For Plastic Parts

1. Free reference quotation with DFM 2. Free consult services 3. Free mould trial for 3times 4. Free part design improve if make moulds/project in AE 5. Free maintenance for in house production mold with tooling life. 6. Signed Non Disclosure Agreement before work 7.1 key contact, 1 team back-support always 8. Well management and precision quality ensure 9. Over 15 years' expertise since 2005 10.7/24 services for on time delivery

Email Details -

Injection Plastic Molding For Medical Devices

1.Plastic Injection Molds for different industry Such as household mold, automotive mold, medical mold, window and door mold, high-speed rail mold, aircraft mold etc. 2.Plastic injection mold products in different materials Such as abs mold, pp mold, pc mold, hdpe mold, pom mold, hdpe mold, nylon mold, tpu mold, tpe mold etc. 3.Professional design team could help you to design and modify the drawing. QC team to inspect all the parts before shipment to ensure the good quality.

Injection Plastic Molding Plastic Molding Molding for Medical Devices Injection Plastic Molding for MedicalEmail Details -

Custom Plastic Injection Molding Universal Mold

1:Strong Full-Auto Production Competence. 2:100% Quality Inspection from raw material to finish products. 3:Over 15 years of manufacturing experience and our capital of more than RMB140,000,000. 4:All of our employees must finish operation training class before running into production and each month we will have a new training class to improve skills, teach them safe operation and so on. 5:We have passed ISO9001 Certificates, all our operations meet Chinese Politics and Environment Protections.

Universal Mold Universal Plastic Mold Universal Plastic Injection Molding Injection Molding Universal MoldEmail Details