Custom Plastic Injection Molding Universal Mold

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1:Strong Full-Auto Production Competence.

2:100% Quality Inspection from raw material to finish products.

3:Over 15 years of manufacturing experience and our capital of more than RMB140,000,000.

4:All of our employees must finish operation training class before running into production and each month we will have a new training class to improve skills, teach them safe operation and so on.

5:We have passed ISO9001 Certificates, all our operations meet Chinese Politics and Environment Protections.

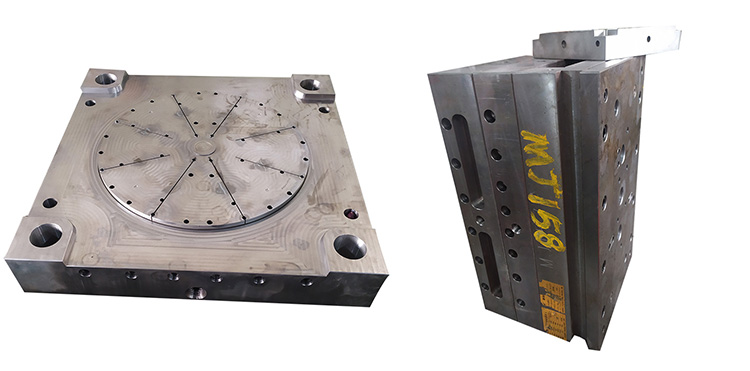

Custom Plastic Injection Molding Universal Mold

Plastic Injection Mould Specification:

Product name | Custom Plastic Injection Molding Universal Mold |

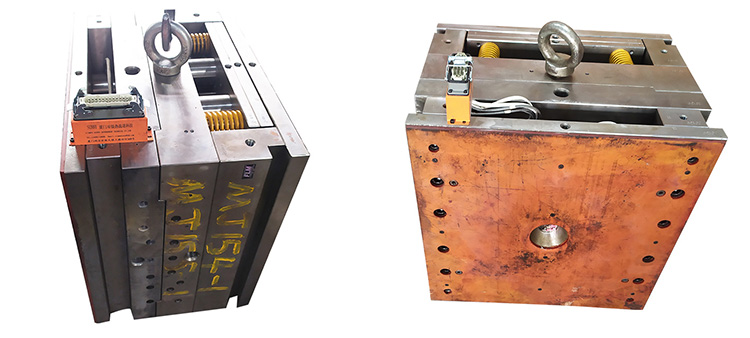

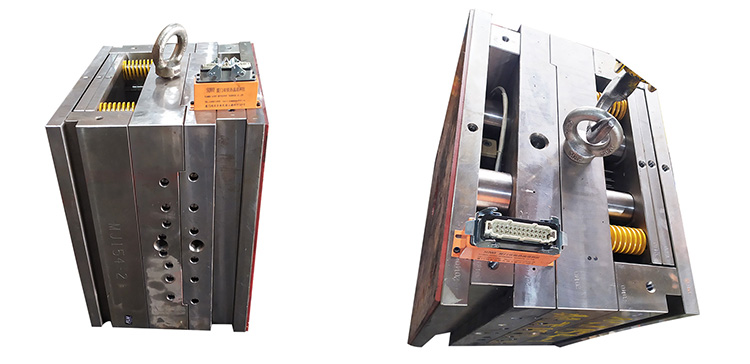

Mould base | Standard mould base, LKM, HASCO etc. |

Application | Home, Industry,Bathroom,Fitness equipment etc. |

Mould testing | All of the moulds can be well tested before the shipments. Videos for testing the moulds are available. |

Ejection system | Motor/hydraulic cylinder/stripping plate/angle pin, etc. |

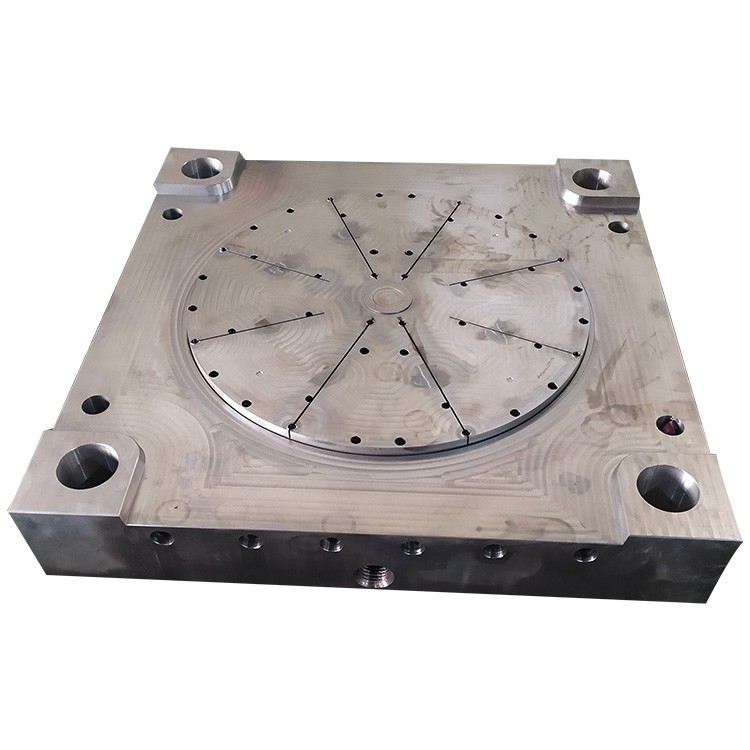

Cooling system | In core baffle and in cavity plate chain drilling type cooling |

Design software | UG, PROE, CAD, CAXA etc. |

Plastic material | ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc. |

Mold Surface treatment | Crude polishing Tech Polish , EDM,High Gloss Polishing , Texture, milling, Graining,IMD ,paiting,mirror polishing, |

Mould life | 300,000-1,000,000 shots |

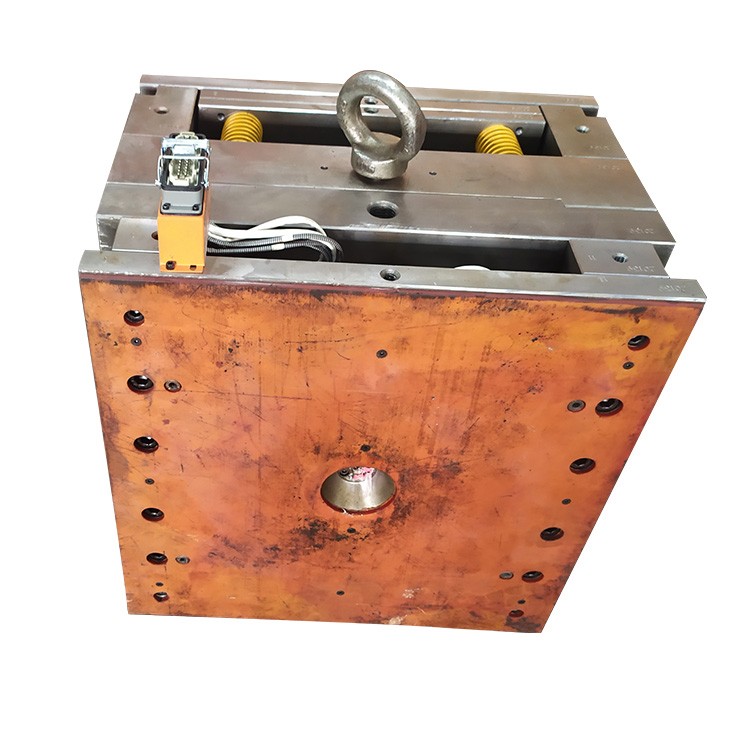

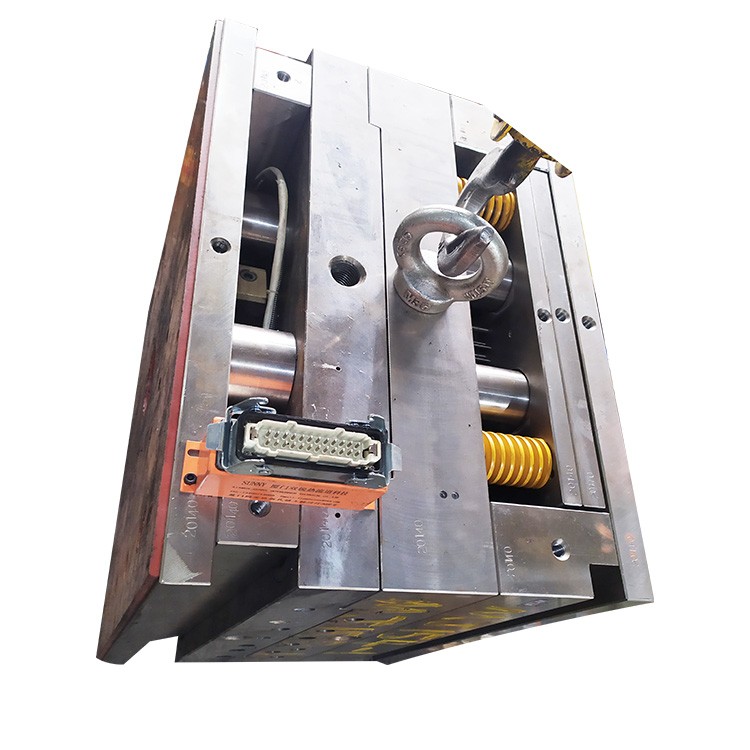

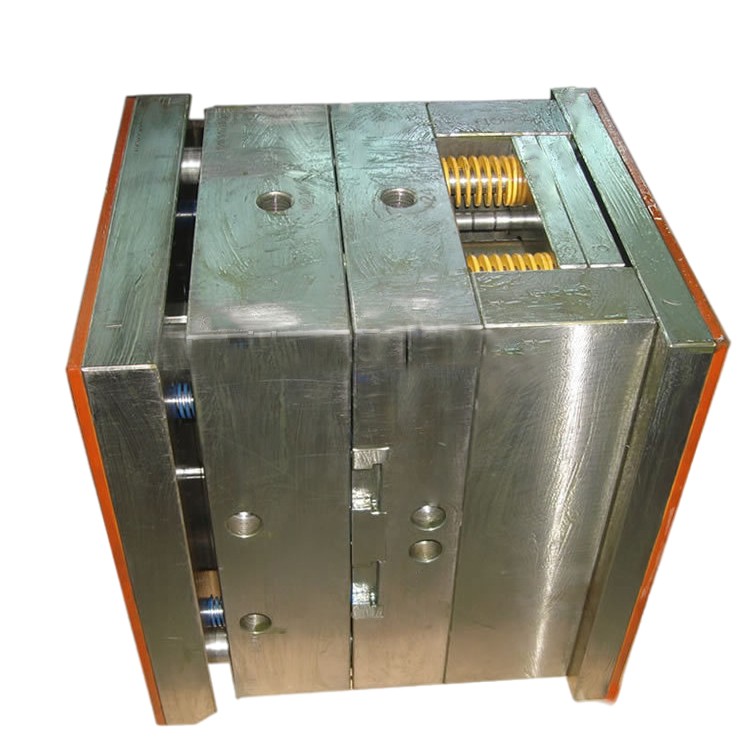

Plastic Injection Mould and Products Show:

Plastic Injection Mould Feature and Application:

1. Efficiency production and automotive operation;

2. Shape can be from simple to complex, the size can be from large to small and the product size is accurate;

3. It is used in the forming and processing fields of mass production and products with complex shapes.

The moulds we make involves house appliance, fitness equipment, electronics, industrial, auto parts, bathroom, medical, over molding and so on.

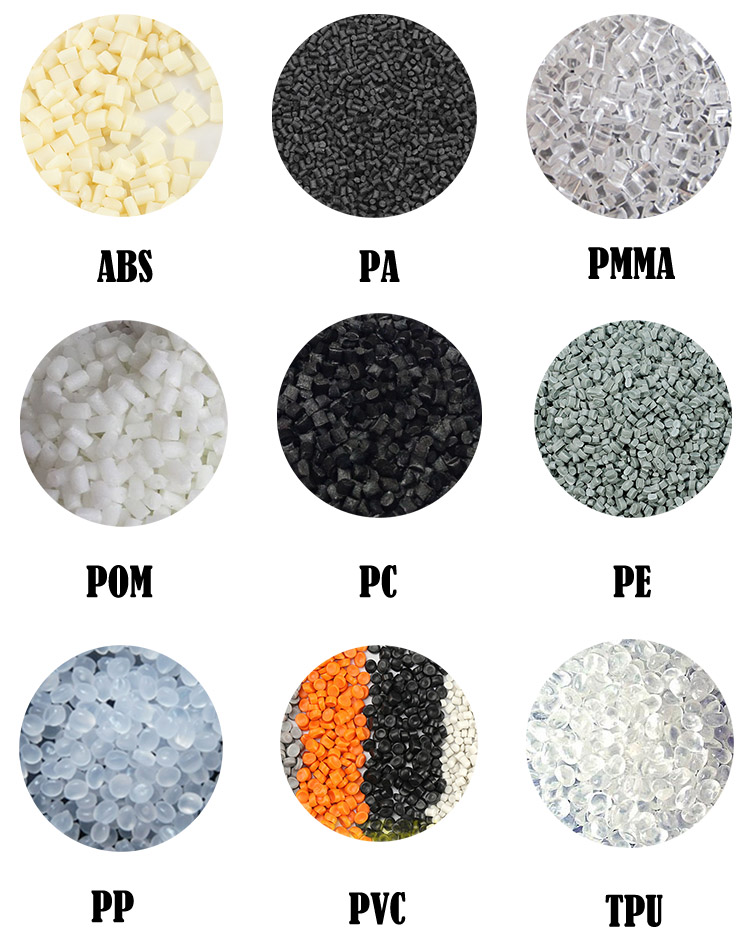

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

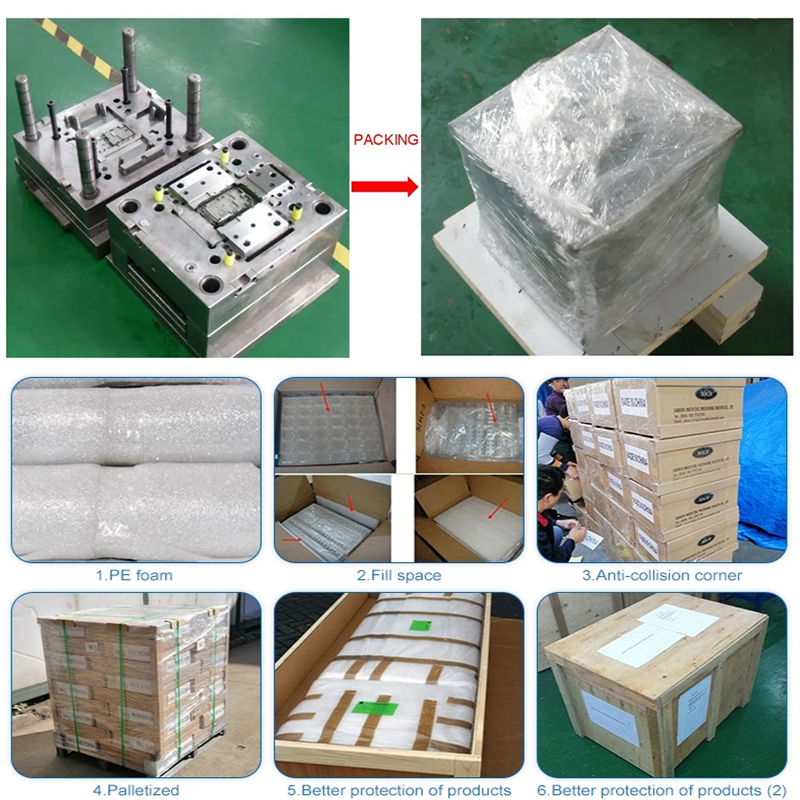

Our Plastic Injection Mould Case Show:

FAQ about Plastic Mould Manufacturing:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection. Sometimes we also make Die casting mold and stamping molds according to our customer’s requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, we can provide steel certificate or hardness certificate to prove.

Q5: Can you make the texture / text / heat treatment /nitriding for the plastic injection mold?

A5: Yes, as plastic mold factory, we have long term cooperated subsidiary factories that do those processes. They are professional and well reputed in our local market.