Injection Mould Auto Connector Plastic Parts Mold

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

Professional experience in one-stop solution on tooling and production;

Satisfy the precision mold requirement in wide rage industry;

Can do from mold design to manufacturing.

1. Fast Quote: Based on 2D or 3D drawing, your sample, even your idea;

2. Mold Design

3. Tooling Maker: Injection mold, stamping die & die casting as well;

4. Plastic Injection Products Production

5. Secondary Process: Offer mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

6.After Service: For your smoothly running machine or product use.

Injection Mould Auto Connector Plastic Parts Mold

Plastic Auto Parts Mould Specification:

| Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.(Hardness 35~55HRC) |

| Mould base | Lkm or According to Customer Requirements |

| Cavity | Will Basis on Qty Plan and Customer′s Requirements |

| Runner | Hot or cold |

| Surface treatment | Polish,texture,sandblasting,chrome |

| Mould life | 300,000-5,000,000 shots |

| Tolerance | 0.01mm -0.05mm |

| Injection Machine Tonnage | 60t-950t |

| Specification | Depends on customer's requirements. |

| Product name | Injection Mould Auto Connector Plastic Parts Mold |

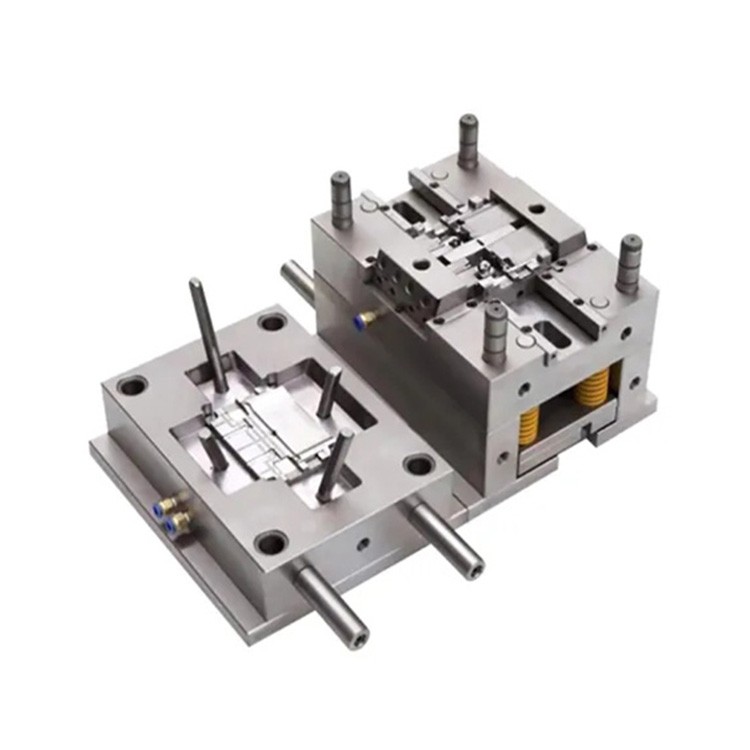

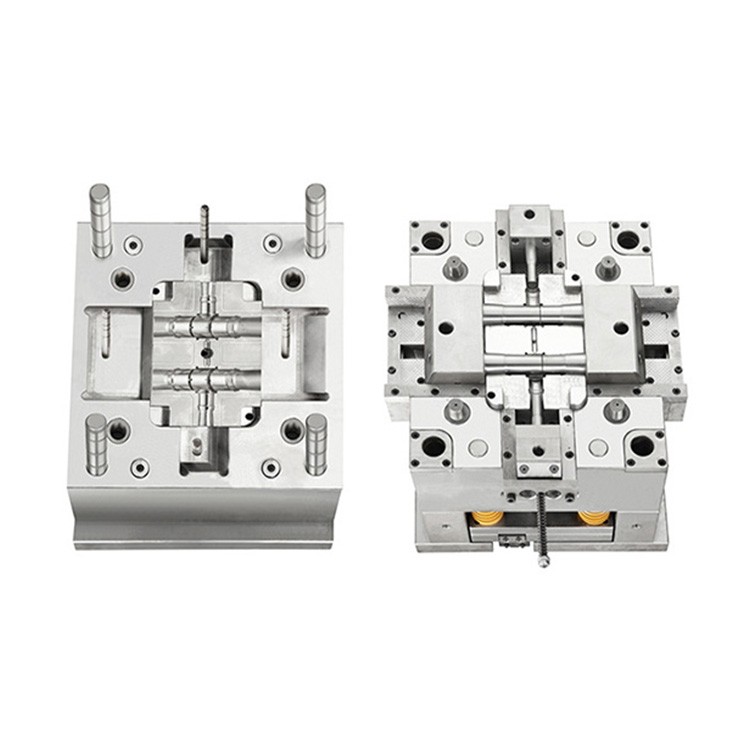

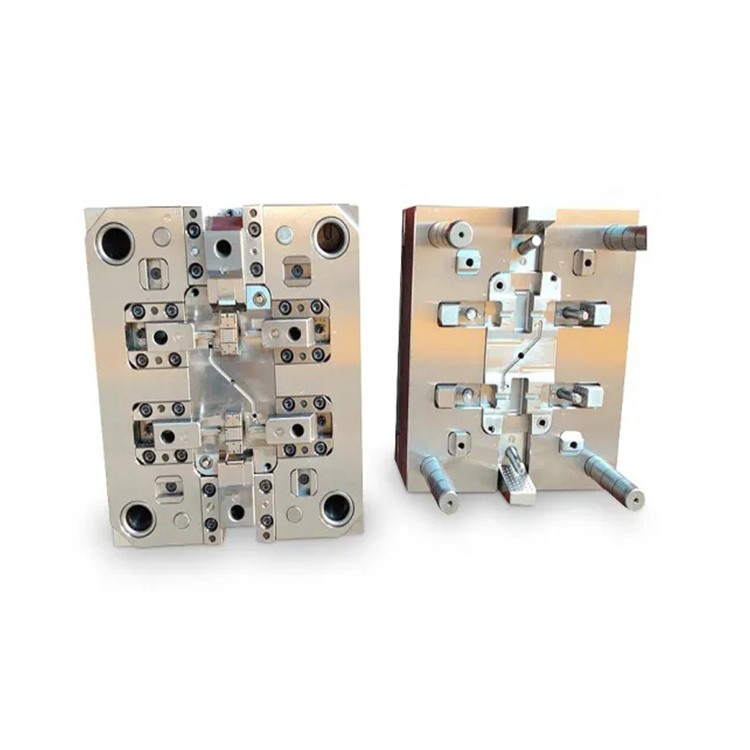

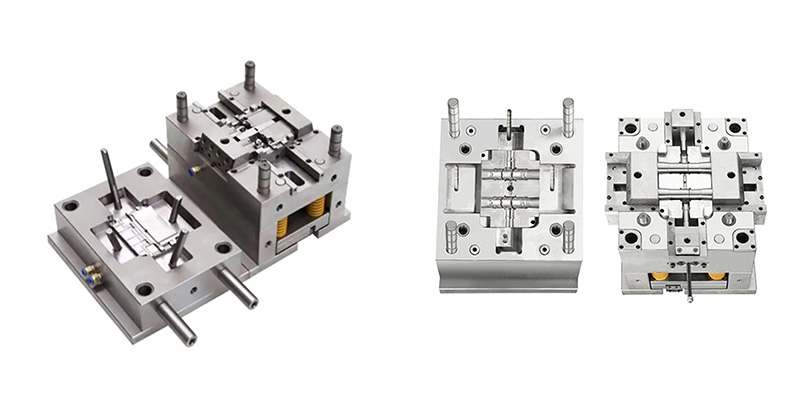

Plastic Auto Parts Mould and products Show:

Our Service:

Household utility ware,auto components,Computer electronics,Electronics components, Marketing samples,Medical & dental products,Model shops, toys, hobby,

New product design & development,Furniture Design,Civil Engineering,Construction, Marine Industry,Garden Products,Military industry.

Plastic Auto Parts Mould Factory Information:

In 2001, the formerly of Xiamen Jinen Plastic Co., Ltd. called Xiamen Jinen Trade Co., Ltd. was established and our main business is sales some kinds of the plastic spare accessories. That is our beginning.

With our business developing, we changed the Xiamen Jinen Trade Co., Ltd. to Xiamen Jinen Plastic Co., Ltd. in 2005. We had got the production license. We are a manufacturer of many kinds of plastic products, we offer the plastic injection service.

In the same year, we brough the machines for the mould, such as CNC machine, EDM, Milling and so on. We are beginning to offer the plastic injection mould making service.

We do not stop our steps, in 2008, we started other relational business of the plastic mould and plastic injection. From 2007, we offer one-stop service for the plastic mould and plastic injection.

In 2014, the Xiamen Jinjiekun Industry Co., Ltd. was established and became the R&D center, we are devoted to R&D, production, processing and sales and have a complete and scientific quality management system.

In 2016, our production value reached 80 Million RMB (about 12.5 Million U.S. dollar) and we had more than 100 workers, at this year, we also had a party for 10 years.

In 2018, we introduced some arm machines and other more machine to instead of artificial that is our first step in the mechanization.

In 2020, although affected by the COVID-19, our production value was still overfulfilled 1 Billion RMB, reached to 1.5 Billion RMB (about 21.5 Million U.S. dollar).

This year we had bought our own building as our workshop area more than 10,000 square meters and we will move to the new building before 2023.

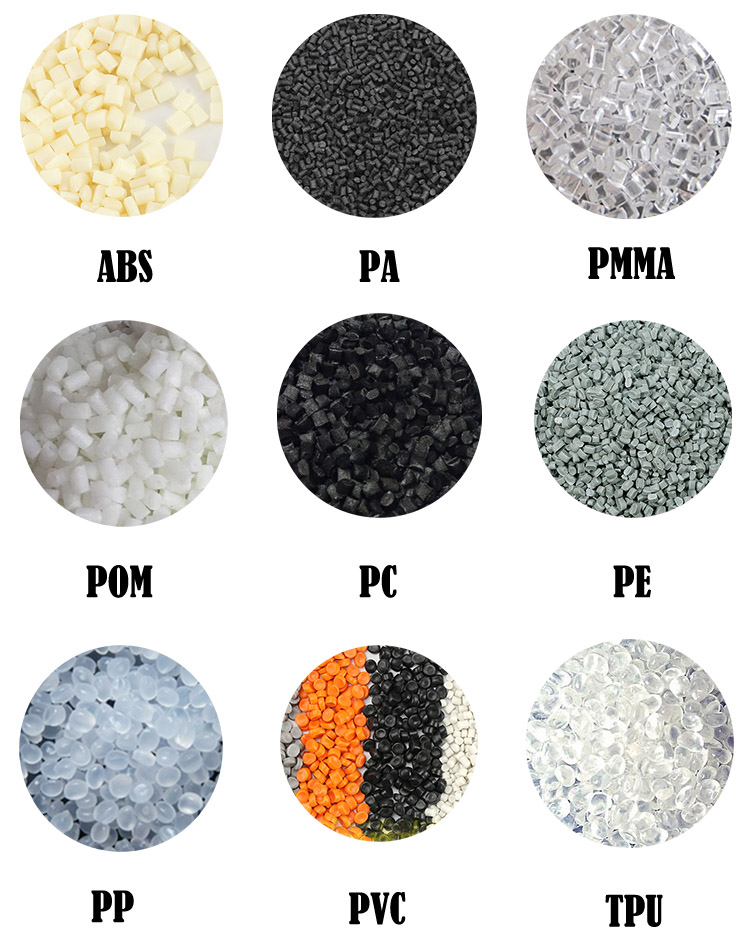

Plastic Raw Material:

FAQ:

Q : How can I get your quotation ?

A : Please provide us information as below :

1) 3D Drawing (STEP, IGS, STL) or 2D/images with Dimension

2) Product Material you are into or suggested by us and Order Quantity

Q: How you do the quality control?

A:

1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out.

Q: What should we do if we receive defective products?

A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q: How to pack the moulds and products?

A:

1). For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer’s request to pack.