mould

-

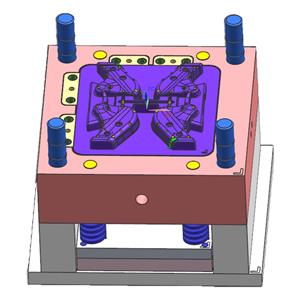

Plastic Injection Insert Overmolding Mould

1. Overmolding takes a part and then overlays another layer of plastic injection molding material over it. One example would be taking a plastic handle and overmolding a soft silicone grip; 2. OEM&ODM projects are highly welcomed, we have strong R&D team, can help modify drawings; 3. The order will be produced exactly according to order details and proofed samples, our QC will submit inspection report before shipment; 4. Over Plastic – It's possible to overmold plastic onto plastic. First the primary, more rigid plastic component is molded and then the more durable plastic is molded over the previous plastic part.

Overmolding Mould Injection Overmolding Mould Plastic Overmolding Mould Plastic Injection Overmolding MouldEmail Details -

Plastic Moulding Medical Injection Mould

1. We can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 2. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 3. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. 4. More than 15years experience for plastic injection mould and plastic injection and developing capability. 5. Enough and many kinds of injection machines to ensure the quantity;

Email Details -

Universal Product Industrial Plastic Injection Mould

For Plastic Injection Mould: 1. High quality raw material to ensure the high quality of the plastic injection mould; 2. Fast delivery, if the sample plastic injection mould, we can finish in 10days; 3. More than 800 mould making experience; 4. Can offer plastic injection making and injection plastic parts, silk screen print and spray paint one stop service. For Plastic Injection Products: 1. Advance injection machine to ensure the quality; 2. Enough and many kinds of injection machines to ensure the quantity; 3. High productivity;

Industrial Plastic Injection Mould Universal Plastic Mould Universal Industrial Plastic Mould Universal Industrial Injection MouldEmail Details -

Plastic Mould Injection Molding For Custom Plastic Parts

1. We are a manufacturer specialized in OEM and ODM plastic injection mould and plastic injection parts from design to rapid prototype to mold to mass production for more than 15 years. 2. We can assemble a complicated products. Providing samples with important dimensions and customizing inspection report material certification to customers for validation and verification. 3. Equipment includes CNC, EDM, grinding machine, injection machine (from 60ton to 900ton), we can supply high precision and complex injection molds and products . 4. We offer unique solutions to your products at a competitive price and best service. 5. Strict quality control. The factory has the most advanced testing equipment to ensure the precision of the mold. 6. Excellent R&D teams, Professional technicians and rich experienced workers

Plastic Mould Injection Molding Plastic Mould for Custom Plastic Parts Molding for Custom Plastic Parts Mould for Custom Plastic PartsEmail Details -

Precision Injection Molding Plastic Mould

Production capacity: Our factory is working 24 hours and 28 days every month and with more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. Quality control and test: It has many times of quality check for every order, beginning from raw material check to package check. Every production line has at least two QC staff for random check and regular check. Test: manufactory testing machine includes rubber tension tester, rubber vulcanization instrument, durometer, calipers, ageing oven for Density test, Elongation at break, Bonding strength, Pulling force test, twisting force test, Rergarding other test like anti-high/low temperature which will be tested by Third Party Testing Center as customer required.

Injection Molding Plastic Injection Molding Plastic Mould Precision Injection Molding Precision Plastic MouldEmail Details -

Automobile Moulds Plastic Injection Parts

We have our own molds plant. Our mold engineers have skill of using UG, Pro/e, SolidWorks, CAD and other 3D design software to design the molds. We have Large CNC machining centers, CNC engraving machines, EDM spark molding machines and Line cutting machines etc to produce the molds. We manufacture and export Custom Plastic Products to USA, Canada and European countries used for vary applications of Household, fitness equipment, Industrial, Auto, Electronics and Construction etc.

Email Details