plastic parts

-

Abs Plastic Parts Molding

1.We have 15 years of experience in mold manufacturing and injection molding services. We can customize products according to drawings, open molds and process them as agents. Customized parts materials include ABS, PE, PP, EEA, EVA, PVC, etc. 2.The company is located in Xiamen, Fujian, China, with convenient port transportation and air transportation, short transportation time, and can receive urgent orders.

Email Details -

Hot

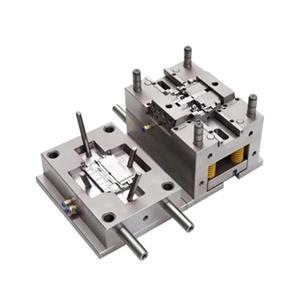

Injection Mould Auto Connector Plastic Parts Mold

Professional experience in one-stop solution on tooling and production; Satisfy the precision mold requirement in wide rage industry; Can do from mold design to manufacturing. 1. Fast Quote: Based on 2D or 3D drawing, your sample, even your idea; 2. Mold Design 3. Tooling Maker: Injection mold, stamping die & die casting as well; 4. Plastic Injection Products Production 5. Secondary Process: Offer mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 6.After Service: For your smoothly running machine or product use.

Plastic Parts Mold Injection Mould Plastic Parts Mold Auto Plastic Parts Mold Injection Auto Plastic Parts MoldEmail Details -

Hot

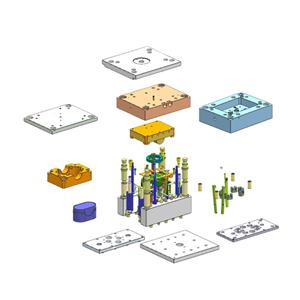

Injection Plastic Parts Mould For Industrial

One-stop Service: Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services; Rich Experience: High Quality, Competitive Price and Fast Delivery Time more than 15years experience for plastic injection mould and plastic injection and developing capability; Advance Equipment: Imported sophisticated production and testing equipment with high stability.

Injection Plastic Parts Mould Plastic Parts Mould for Industrial Injection Plastic Mould for Industrial Plastic Mould for IndustrialEmail Details -

Plastic Shower

1. One-stop Service:Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services; 2. Rich Experience:more than 15years experience for plastic injection mould and plastic injection and developing capability; 3. High Quality, Competitive Price and Fast Delivery Time: more than 15years experience for plastic injection mould and plastic injection and developing capability; 4. Advance Equipment: Imported sophisticated production and testing equipment with high stability. 5. Fast Quote: Based on 2D or 3D drawing, your sample, even your idea; 6. Tooling Maker: Injection mold, stamping die & die casting as well; 7. Secondary Process: Offer mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 8. After Service: For your smoothly running machine or product use.

Bathroom Mould Plastic Parts Injection Moulding Bathroom Mould Injection Moulding Bathroom Plastic Parts Injection MouldingEmail Details -

Injection Molding Custom Plastic Parts

Plastic Injection Products Feature and Application: 1. Efficiency production and automotive operation; 2. Shape can be from simple to complex, the size can be from large to small and the product size is accurate; 3. It is used in the forming and processing fields of mass production and products with complex shapes. The application we involve house appliance, fitness equipment, electronics, industrial, auto parts, bathroom, medical, over molding and so on.

Custom Plastic Parts Injection Molding Plastic Parts Injection Molding Custom Plastic Parts Injection Custom Plastic PartsEmail Details -

High Precision Custom Injection Plastic Parts

1.Product engineering, development, consultation and the latest in manufacturing simulation software. 2. A strong dedicated workforce committed to promoting and customer service. 3. Collaboration during the mold design process between our customers, management, and our employees to implement the best possible concept. 4. Our unique capacity to create solutions that replace expensive, fabricated steel products. 5. Provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

Injection Plastic Precision Injection Plastic Custom Injection Plastic Precision Custom Injection PartsEmail Details -

Multi Or Single Cavity Plastic Parts Injection Molding

We continually works on development and improvement for holding the management tenets of integrity, Quality first and Credit Tops. By far, We are in possession of one lot advanced equipment and one excellent team. Our Products have already been setup good relationship with many domestic and oversea clients, We serve for customers with advanced technology, good quality, reasonable price and considerate after sale service, Our products are famous and get good reputation in both domestic market and oversea market.

Email Details -

Molding Injection Plastic Parts Mould

We have professional engineering team which has more than 10 engineers who is good at plastic injection mold design, we can offer one stop service from drawing design, tools & samples manufacturing, mass productions, packing till shipment. Our sales team are thoughtful and good at understanding your idea and points, where help to make your work much eaiser. 24*7 comminication service, whenever you need us, we are here for you. Advance and enough injection machines to ensure the quality and quantity, the machine we have: High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Machines from 60-950T available.

Molding Injection Molding Injection Plastic Parts Molding Injection Plastic Parts Mould Plastic Parts MouldEmail Details -

Household Molding For Plastic Injection Parts

For Plastic Injection Mould: 1. Advance and enough equipment, high speed CNC, standard CNC, EDM, wire cutting, WEDM and grinder; 2. With more than 10 engineers can provide design service for plastic products and plastic injection mold, no matter 2D or 3D drawing; 3. With more than 800 sets plastic injection mold making experience since 2007; 4. Fast deliver conventional products, the lead time depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Molds are very simple and not big size, we can work out within 15 days.

Household Molding Molding for Plastic Injection Molding for Plastic Parts Household Molding Injection PartsEmail Details