molding injection

-

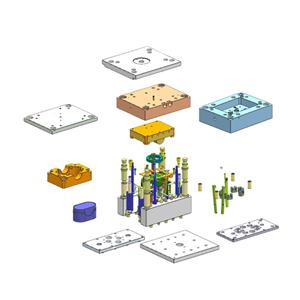

Walking Machine Molding Plastic Injection Mould

1. Have experience for mould; 2. 3D Drawing service from plastic to plastic injection moulding tool design; 3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts; 4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts; 5. We have professional plastic injection mold tooling designer and plastic part producing line; 6. Plastic Injection Mould OEM & ODM Services; 7. ISO 9001, ISO 14001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory.

Molding Plastic Mould Molding Injection Mould Walking Machine Molding Walking Machine Plastic Injection MouldEmail Details -

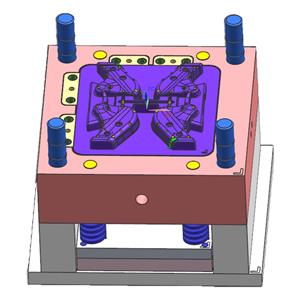

Injection Molding Precision Injection Plastic Mould

1. High quality and factory price for plastic injection mould service; 2. Plastic injection mould design and making service and plastic injection service for over 30 countries; Provide high-volume injection molding solutions; 3. One-stop service from plastic injection mould making to plastic injection and assembly; 4. Collaboration during the mold design process between our customers, management, and our employees to implement the best possible concept; 5. Our unique capacity to create solutions that replace expensive, fabricated steel products.

Email Details -

Molding Injection Plastic Parts Mould

We have professional engineering team which has more than 10 engineers who is good at plastic injection mold design, we can offer one stop service from drawing design, tools & samples manufacturing, mass productions, packing till shipment. Our sales team are thoughtful and good at understanding your idea and points, where help to make your work much eaiser. 24*7 comminication service, whenever you need us, we are here for you. Advance and enough injection machines to ensure the quality and quantity, the machine we have: High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Machines from 60-950T available.

Molding Injection Molding Injection Plastic Parts Molding Injection Plastic Parts Mould Plastic Parts MouldEmail Details -

Household Molding For Plastic Injection Parts

For Plastic Injection Mould: 1. Advance and enough equipment, high speed CNC, standard CNC, EDM, wire cutting, WEDM and grinder; 2. With more than 10 engineers can provide design service for plastic products and plastic injection mold, no matter 2D or 3D drawing; 3. With more than 800 sets plastic injection mold making experience since 2007; 4. Fast deliver conventional products, the lead time depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Molds are very simple and not big size, we can work out within 15 days.

Household Molding Molding for Plastic Injection Molding for Plastic Parts Household Molding Injection PartsEmail Details -

Custom Molding Plastic Injection Products

One-stop service: provides service of part design, prototype making, mold design, mold production, mass production and assembly service in house. We are cooperating with many clients all over the world and have a deep understanding of the mold industry, our experience range from simple design to challenging technical parts. Quality Guarantee: free plastic injection mold maintains service and a strict quality control process.

Plastic Injection Custom Injection Custom Plastic Injection Products Custom Molding Plastic ProductsEmail Details -

Precision Injection Molding Plastic Mould

Production capacity: Our factory is working 24 hours and 28 days every month and with more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. Quality control and test: It has many times of quality check for every order, beginning from raw material check to package check. Every production line has at least two QC staff for random check and regular check. Test: manufactory testing machine includes rubber tension tester, rubber vulcanization instrument, durometer, calipers, ageing oven for Density test, Elongation at break, Bonding strength, Pulling force test, twisting force test, Rergarding other test like anti-high/low temperature which will be tested by Third Party Testing Center as customer required.

Injection Molding Plastic Injection Molding Plastic Mould Precision Injection Molding Precision Plastic MouldEmail Details