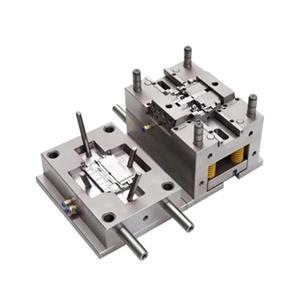

mould

-

Custom Plastic Products Molding Injection Mould

Provide high quality custom plastic injection molded parts; Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET etc.; Different injection molded parts can pass different certification such as UL test, V0 fire resistant test, FDA test, REACH test, SGS test and IP65; Provide different surface treatment for injection molded parts. Commonly use surface treatment for injection molded parts as: Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI; Besides making injection molded parts, we also provide printing, welding, assembly and packing service;

Email Details -

Car Lampshade Molding

1. High-strength material: high-strength materials are used to improve the impact resistance and deformation resistance of the lampshade. 2. Weather resistance: After special treatment, it has good weather resistance and can adapt to various harsh climatic conditions. 3. High light transmittance: unique design, improve light transmittance, and ensure lighting effect. 4. Personalized customization: According to customer needs, personalized customization services can be provided to meet the needs of different models and appearance designs.

Email Details -

Cold Hot Runner Precision Plastic Injection Mould

Advance Service before sales 1. We can provide comprehensive and professional Suggestions on equipment selection. 2. Energy consumption calculation and investment income analysis can be provided. 3. Provide tailor-made CAD drawings of workshop layout and product optimization suggestions Advantages of tech teams 1.More than 800 sets per year mold making enable us to have rich experience across kinds of industries. 2. Enough and advance equipments for customer product characteristics. 3. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry. Advantages of after-sales team 1. Lifetime free service for the machine. 2. Quick response all day long. 3. Set up domestic service team and international service team. 4. Technicians also master the debugging and maintenance of auxiliary equipment.

Precision Plastic Injection Mould Cold Hot Runner Plastic Injection Mould Plastic Injection Mould Hot Runner Plastic Injection MouldEmail Details -

Hot

Injection Mould Auto Connector Plastic Parts Mold

Professional experience in one-stop solution on tooling and production; Satisfy the precision mold requirement in wide rage industry; Can do from mold design to manufacturing. 1. Fast Quote: Based on 2D or 3D drawing, your sample, even your idea; 2. Mold Design 3. Tooling Maker: Injection mold, stamping die & die casting as well; 4. Plastic Injection Products Production 5. Secondary Process: Offer mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 6.After Service: For your smoothly running machine or product use.

Plastic Parts Mold Injection Mould Plastic Parts Mold Auto Plastic Parts Mold Injection Auto Plastic Parts MoldEmail Details -

Hot

Plastic Mould For Mobile Phone Injection Cover

1. Fast Quote: Based on 2D or 3D drawing, your sample, even your idea; 2. Mold Design: With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customer; 3. Tooling Maker: Injection mold, stamping die & die casting as well and provide high-volume injection molding solutions;; 4. Plastic Injection Products Production: Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. 5. Secondary Process: Provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 6. After Service: For your smoothly running machine or product use.

Plastic Mould Plastic Mould for Injection Cover Mould for Injection Cover Plastic Mould for Mobile Phone Injection CoverEmail Details -

Hot

Injection Plastic Parts Mould For Industrial

One-stop Service: Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services; Rich Experience: High Quality, Competitive Price and Fast Delivery Time more than 15years experience for plastic injection mould and plastic injection and developing capability; Advance Equipment: Imported sophisticated production and testing equipment with high stability.

Injection Plastic Parts Mould Plastic Parts Mould for Industrial Injection Plastic Mould for Industrial Plastic Mould for IndustrialEmail Details -

Hot

Auto Plastic Parts Molds

Product Process: 1. Mold Design Control 2. Mold Steel Hardness Inspection 3. Mold Electrodes Inspection 4. Mold Core and Cavity Steel Dimension Inspection 5. Mold Pre-Assembly Inspection 6. Mold Trial Report and Samples Inspection 7. Pre-Shipment Final Inspection 8. Export Product Package Inspection

injection mold manufacturing plastic injection molding injection mould maker plastic injection partsEmail Details -

Spinning Bike Pedal

1. We use ABS/HIPS material to make pedals. 2. Customer-designed LOGO patterns can be provided. 3. Color: can be customized 4. Customized appearance design: accepted 5.Service: OEM or ODM 6. Sample: Available 7. Sample fee: Buyers need to provide express fee 8. Sample delivery time: within 15 days 9. Payment method: 30% prepaid by T/T, the balance is paid before shipment 10. Production time: 7-15 days 11. Delivery port: Xiamen

Email Details -

Toilet Seat

1. We use Plastic material to make toilet seat. 2. Customer-designed LOGO patterns can be provided. 3. Color: can be customized 4. Customized appearance design: accepted 5.Service: OEM or ODM 6. Sample: Available 7. Sample fee: Buyers need to provide express fee 8. Sample delivery time: within 15 days 9. Payment method: 30% prepaid by T/T, the balance is paid before shipment 10. Production time: 20-45 days 11. Delivery port: Xiamen

Email Details