Plastic Injection Insert Overmolding Mould

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. Overmolding takes a part and then overlays another layer of plastic injection molding material over it. One example would be taking a plastic handle and overmolding a soft silicone grip;

2. OEM&ODM projects are highly welcomed, we have strong R&D team, can help modify drawings;

3. The order will be produced exactly according to order details and proofed samples, our QC will submit inspection report before shipment;

4. Over Plastic – It's possible to overmold plastic onto plastic. First the primary, more rigid plastic component is molded and then the more durable plastic is molded over the previous plastic part.

Plastic Injection Insert Overmolding Mould

Overmolding Description:

Product Description | plastic Overmolding |

Mould material | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

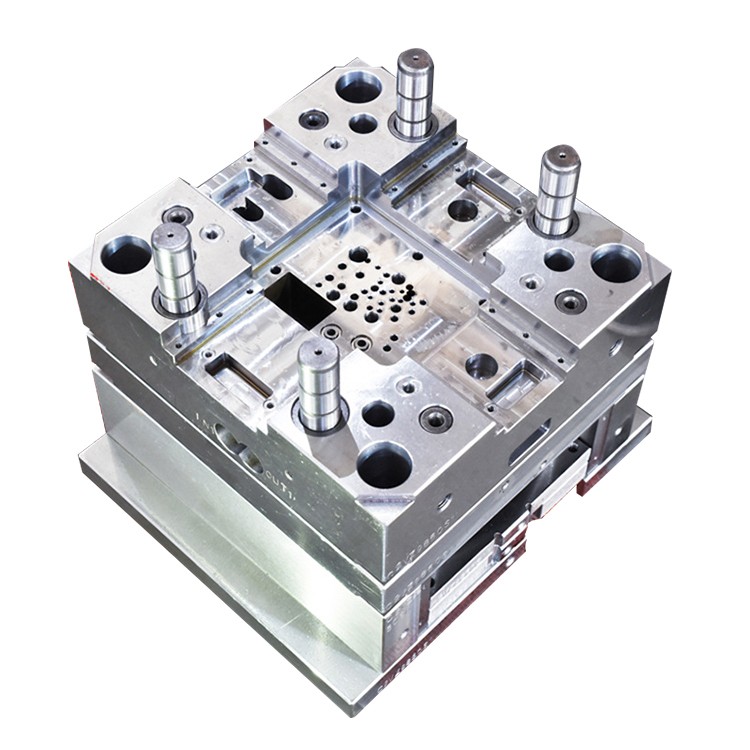

Mould base | Standard mould base,HASCO,FUTABA,DME,LKM |

Surface treatment | Polish,texture,sandblasting,chrom |

Mould life | 250000-300000shots |

Delivery time | Sample making 7-10 days,mold making 15-40 days |

Pacakge | Standard export wooden case |

Specification | Depends on customer's requirements. |

Mould precision | +/-0.03mm |

Mould size | According to your 2D, 3D Drawing |

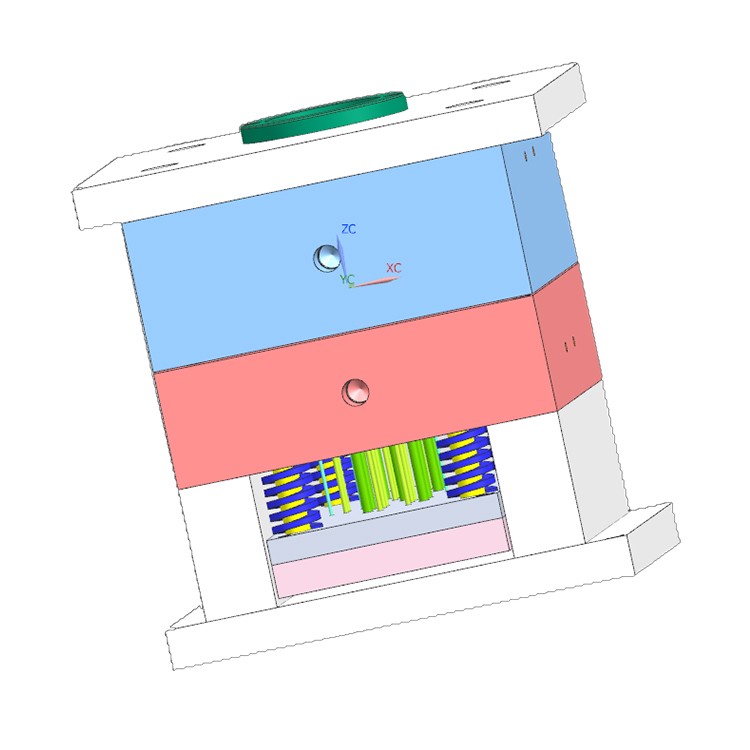

Process for overmolding — Plastic Injection Molding

1. Offer your 3D CAD file to get your mold and part quote.

2. Add your requirements for overmolding

3. After order confirmation, We will starts the mold and part order process.

4. Tooling design,upon design approval, we begin building your injection mold.

5. Examines samples for approval.

6. Part production begins.

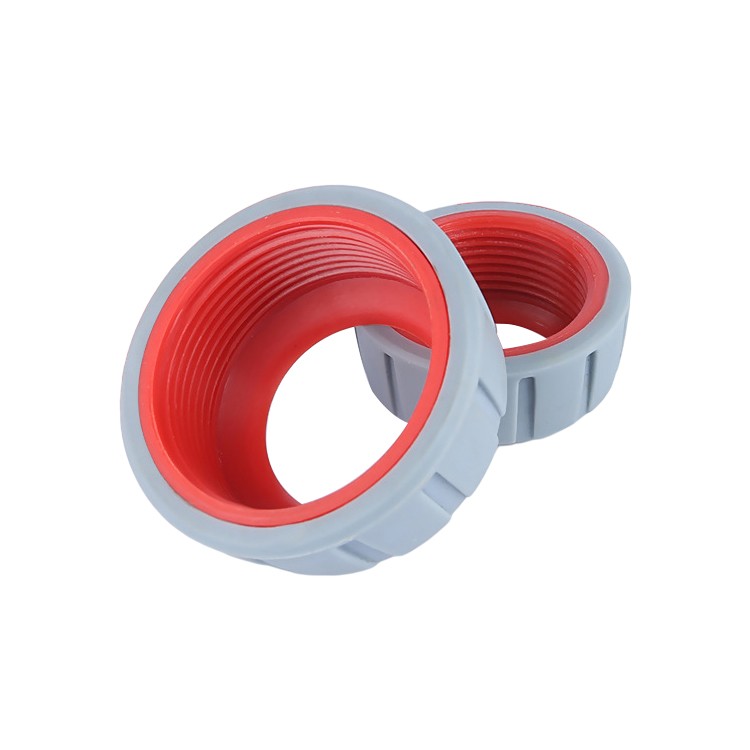

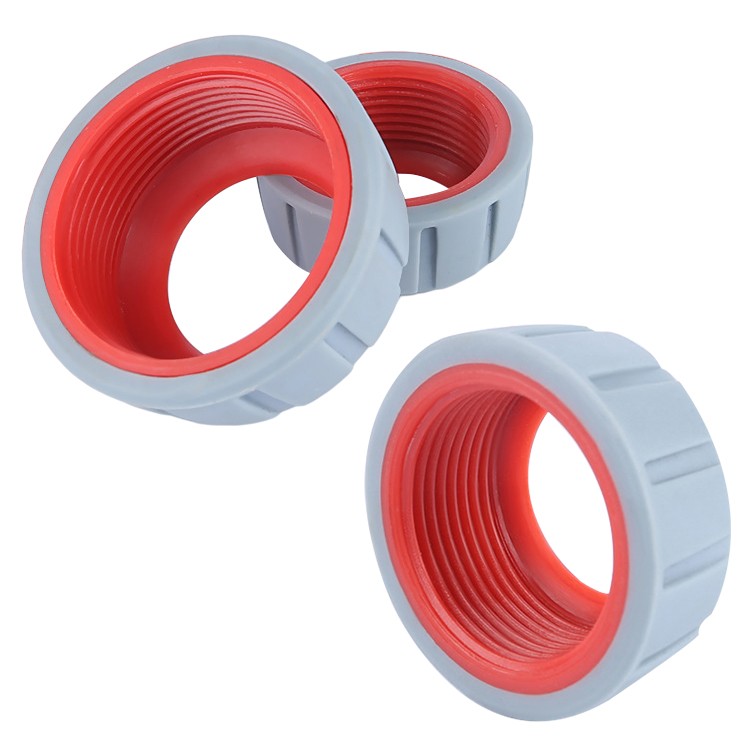

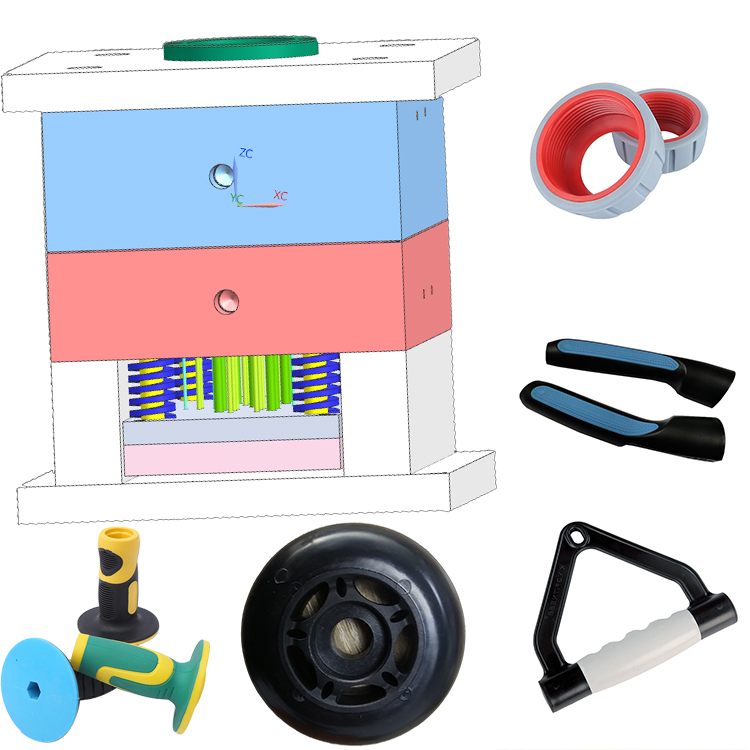

Plastic Overmolding and Parts Show:

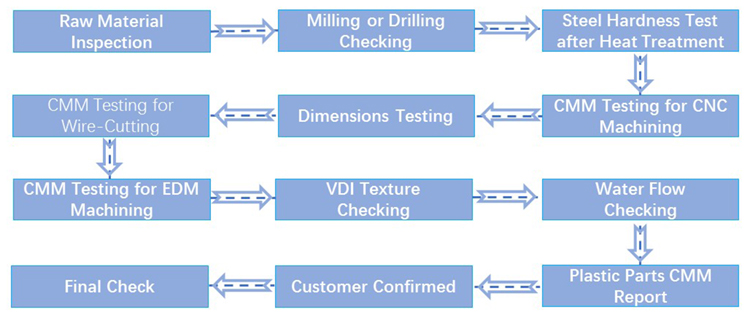

Quality Control Process:

Certification:

Packing and Logistics:

FAQ:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection. Sometimes we also make Die casting mold and stamping molds according to our customer’s requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, we can provide steel certificate or hardness certificate to prove.

Q5: Can you make the texture / text / heat treatment /nitriding for the plastic injection mold?

A5: Yes, as plastic mold factory, we have long term cooperated subsidiary factories that do those processes. They are professional and well reputed in our local market.

Q6: How long is the lead-time for a plastic injection mold?

A6: It all depends on the mold’s size and complexity. Normally, the lead time is 25_45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q7: Do you make spare parts for your customer?

A7: Yes, we will provide spare parts for the mold if needed or required by client.

Q8: How do you pack the china plastic moulds?

A8: We pack the plastic moulds with wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any movement.