molding

-

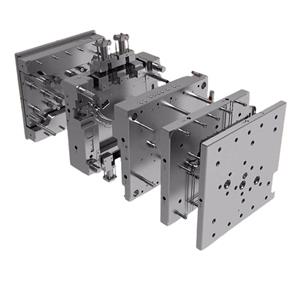

Plastic Injection Molding Mould For Plastic Parts

1. We can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 2. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 3. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Plastic Injection Molding Mould Mould for Plastic Parts Plastic Molding Mould Injection Mould for Plastic PartsEmail Details -

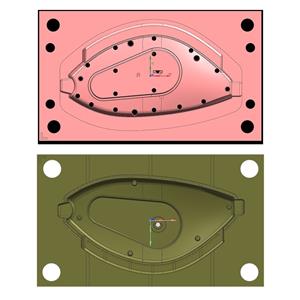

Plastic Cover Mould Injection Plastic Molding

1. 7500 square meters factory mainly provides CNC machining service and plastic injection service. 2. ISO certificated,supports third-party verification. 3. Fast deliver conventional products, the lead time depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days. 4. Engineering service provided, with more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

Mould Injection Plastic Plastic Cover Molding Mould Injection Plastic Molding Plastic Cover Injection MoldingEmail Details -

Precision Injection Molding Plastic Products

We have a professional engineers design team with more than people and can use CAD, Pro-E, UG, Solidworks etc. to ensure all kinds of design.Before the project started: 1. If you have 3D STEP/IGES/X_T drawing or 2D drawing, please send it to us before quotation, then we will do DFM and mould design for you. 2. If you only have samples please provide us the samples, we can design 3D drawing for you and quotation. We have enough and advance equipment and machines, such as high CNC and other equipment for plastic mold making, 60 to 950T plastic injection machines for the plastic mold, assembly line for spray print and other machine for us to provide the one-stop service.

Precision Plastic Products Injection Molding Plastic Products Injection Plastic Products Precision Injection ProductsEmail Details -

Plastic Injection Molding Components

1. We are a specialized in plastic injection mold and plastic parts molding. We have produced more than 600 sets of molds per year and have been molding millions of plastic parts. The mold and plastic parts we made are widely applying in electronic, household, automotive, fitness equipment and medical industry. 2. Excellent R&D team: with more than 10 engineers for plastic product and plastic injection mold design, programming, project managers. we are using CAD/CAE/CAM software to do the design; 3. Efficiency production: it depends on the products' size and complexity. Normally, the lead time is 15-25 days.

Email Details -

Plastic Injection Mould Parts Molding

1.Word Top Equipment: High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine from 60-950T available. 2. More Than 15 Years Mould Making and Plastic Injection: More than 800 moulds making experience and rich experience in plastic injection since the year of 2007 3. More Than 100 Staff and 5S Management Srandrad: With more than 10 engineers for design service, more than 10 managers for management and about 60 staff for production; 4. Large Square Workshop: Our workshop area is about 7500 square meters.

Plastic Injection Mould Parts Plastic Injection Parts Molding Injection Mould Parts Molding Plastic Mould Parts MoldingEmail Details -

Custom Molding Plastic Injection Products

One-stop service: provides service of part design, prototype making, mold design, mold production, mass production and assembly service in house. We are cooperating with many clients all over the world and have a deep understanding of the mold industry, our experience range from simple design to challenging technical parts. Quality Guarantee: free plastic injection mold maintains service and a strict quality control process.

Plastic Injection Custom Injection Custom Plastic Injection Products Custom Molding Plastic ProductsEmail Details -

Injection Mould Plastic Products Molding For Homewares

1. Provide high quality custom plastic injection parts and plastic injection molds; 2. Plastic injection mold parts can be different material such as, ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET etc.; 3. Different plastic injection mold parts can pass different certification, such as UL test, V0 fire resistant test, FDA test, REACH test, SGS test and IP65; 4. Can also provide different surface treatment for plastic injection mold, such as Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding; 5. Beside plastic injection mold parts, we also provide printing, welding, assembly and packing service.

Injection Mould Plastic Products Molding Plastic Products Molding for Homewares Molding for Homewares Injection Products MoldingEmail Details -

Multi Color Plastic Injection Mould Overmolding

1. Professional experience in one-stop solution on tooling and production; 2. Satisfy the precision mold requirement in wide rage industry; 3. Can do from mold design to manufacturing.

Overmolding Plastic Injection Mould Overmolding Multi Color Mould Overmolding Multi Color Injection OvermoldingEmail Details -

Plastic Injection Insert Overmolding Mould

1. Overmolding takes a part and then overlays another layer of plastic injection molding material over it. One example would be taking a plastic handle and overmolding a soft silicone grip; 2. OEM&ODM projects are highly welcomed, we have strong R&D team, can help modify drawings; 3. The order will be produced exactly according to order details and proofed samples, our QC will submit inspection report before shipment; 4. Over Plastic – It's possible to overmold plastic onto plastic. First the primary, more rigid plastic component is molded and then the more durable plastic is molded over the previous plastic part.

Overmolding Mould Injection Overmolding Mould Plastic Overmolding Mould Plastic Injection Overmolding MouldEmail Details