molding

-

OEM Injection Molding Plastic Products

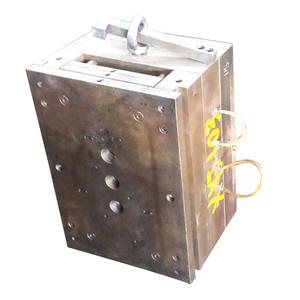

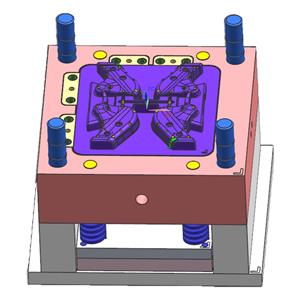

We have introduced many international advanced equipment and machines at home and abroad, including complete CAD/CAE/CAM system, computer three-dimensional measuring instrument, CNC computer controlled EDM center and plastic injection machines from 60T to 950T and the other machines for plastic mold making and plastic injection to ensure us can design and manufacture various mold products according to user requirements. We also have rich experience in plastic mold and plastic injection since 2005. Besides, we also have the advance management system, strict quantity control process and the professional team for sales, R&D, production and after sales service.

OEM Plastic Products OEM Injection Plastic Products OEM Injection Molding Plastic Products OEM Injection ProductsEmail Details -

Two Color Plastic Injection Overmolding

1. Plastic injection mould design and making service and plastic injection service for over 30 countries; 2. Provide high-volume injection molding solutions; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly 4. 4. Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 5. Fast delivery, if the sample plastic injection mould, we can finish in 10days; 6. More than 800 mould making experience;

Injection Overmolding Two Color Plastic Overmolding Two Color Overmolding Two Color Plastic Injection OvermoldingEmail Details -

Custom Plastic Injection Molding For Plastic Parts

1. Free reference quotation with DFM 2. Free consult services 3. Free mould trial for 3times 4. Free part design improve if make moulds/project in AE 5. Free maintenance for in house production mold with tooling life. 6. Signed Non Disclosure Agreement before work 7.1 key contact, 1 team back-support always 8. Well management and precision quality ensure 9. Over 15 years' expertise since 2005 10.7/24 services for on time delivery

Email Details -

Plastic Mould Injection Molding For Custom Plastic Parts

1. We are a manufacturer specialized in OEM and ODM plastic injection mould and plastic injection parts from design to rapid prototype to mold to mass production for more than 15 years. 2. We can assemble a complicated products. Providing samples with important dimensions and customizing inspection report material certification to customers for validation and verification. 3. Equipment includes CNC, EDM, grinding machine, injection machine (from 60ton to 900ton), we can supply high precision and complex injection molds and products . 4. We offer unique solutions to your products at a competitive price and best service. 5. Strict quality control. The factory has the most advanced testing equipment to ensure the precision of the mold. 6. Excellent R&D teams, Professional technicians and rich experienced workers

Plastic Mould Injection Molding Plastic Mould for Custom Plastic Parts Molding for Custom Plastic Parts Mould for Custom Plastic PartsEmail Details -

Precision Injection Molding Plastic Mould

Production capacity: Our factory is working 24 hours and 28 days every month and with more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. Quality control and test: It has many times of quality check for every order, beginning from raw material check to package check. Every production line has at least two QC staff for random check and regular check. Test: manufactory testing machine includes rubber tension tester, rubber vulcanization instrument, durometer, calipers, ageing oven for Density test, Elongation at break, Bonding strength, Pulling force test, twisting force test, Rergarding other test like anti-high/low temperature which will be tested by Third Party Testing Center as customer required.

Injection Molding Plastic Injection Molding Plastic Mould Precision Injection Molding Precision Plastic MouldEmail Details -

Injection Plastic Molding For Medical Devices

1.Plastic Injection Molds for different industry Such as household mold, automotive mold, medical mold, window and door mold, high-speed rail mold, aircraft mold etc. 2.Plastic injection mold products in different materials Such as abs mold, pp mold, pc mold, hdpe mold, pom mold, hdpe mold, nylon mold, tpu mold, tpe mold etc. 3.Professional design team could help you to design and modify the drawing. QC team to inspect all the parts before shipment to ensure the good quality.

Injection Plastic Molding Plastic Molding Molding for Medical Devices Injection Plastic Molding for MedicalEmail Details -

Injection Molding Components Plastic Cover

1. Custom or standard plastic injection mould or plastic injection products. 2. Finishing: high polish, bevelling or common matte surface finishing. 3. Materials including PVC, ABS, PC, PP, PE, EPS, POM, PA, PET, ASA, etc. available. 4. Single extrusion, coextrusion and triextrusion available. 5. Rigid material, soft material, rigid material+flexible material co-extrusion. 6. Product range: plastic frame, seal and gasket for refrigrator, freezer, cold chain and kitchen cabinet, vending machine and air conditioner, and drainage tube, round tube, etc. 7. Features: UV/weather resistant, thermal resistant, durable, anti-noise, good tightness, waterproof, dustproof, sound proof, etc. 8. RoHS and REACH compliance

Plastic Cover Injection Plastic Cover Injection Molding Plastic Cover Injection Components Plastic CoverEmail Details -

Custom Plastic Injection Molding Universal Mold

1:Strong Full-Auto Production Competence. 2:100% Quality Inspection from raw material to finish products. 3:Over 15 years of manufacturing experience and our capital of more than RMB140,000,000. 4:All of our employees must finish operation training class before running into production and each month we will have a new training class to improve skills, teach them safe operation and so on. 5:We have passed ISO9001 Certificates, all our operations meet Chinese Politics and Environment Protections.

Universal Mold Universal Plastic Mold Universal Plastic Injection Molding Injection Molding Universal MoldEmail Details