Plastic Injection Mould Parts Molding

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1.Word Top Equipment:

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine from 60-950T available.

2. More Than 15 Years Mould Making and Plastic Injection:

More than 800 moulds making experience and rich experience in plastic injection since the year of 2007

3. More Than 100 Staff and 5S Management Srandrad:

With more than 10 engineers for design service, more than 10 managers for management and about 60 staff for production;

4. Large Square Workshop:

Our workshop area is about 7500 square meters.

Plastic Injection Mould Parts Molding

Plastic Injection Mould Specification:

Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc. (Hardness 35~55HRC) |

Mould base | Standard mould base, LKM, HASCO etc. |

Factory History | More than 15 years experience in plastic injection mold and clear/transparent plastic parts molding |

Plastic Certification | RoSH, SGS, food grade, Medical grade, UL, UV |

Ejection system | Motor/hydraulic cylinder/stripping plate/angle pin, etc. |

Cooling system | In core baffle and in cavity plate chain drilling type cooling |

Product Name | Plastic Injection Mould Parts Molding |

Plastic material | ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc. |

Surface treatment | Polish, texture, sand blasting, chrome plating |

Mould life | 300,000-1,000,000 shots |

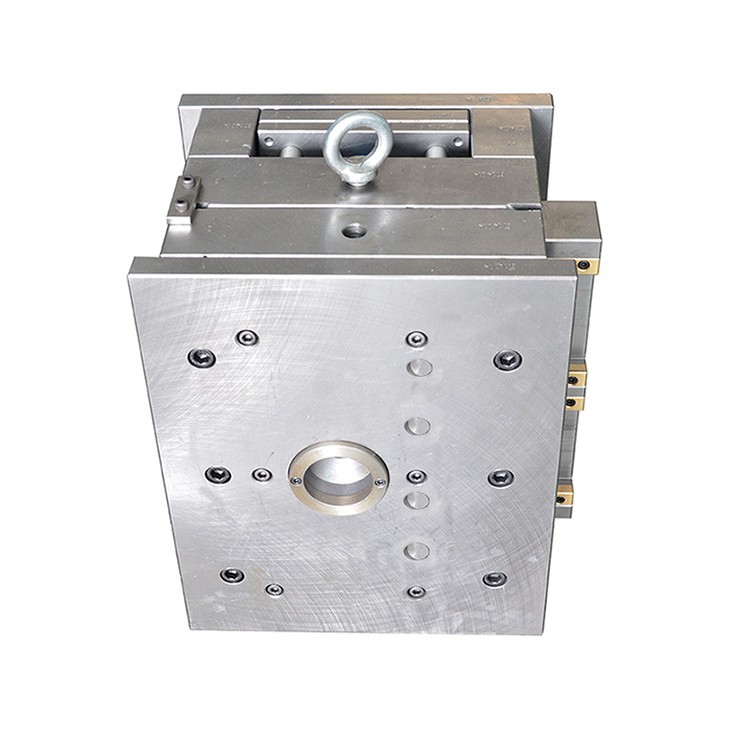

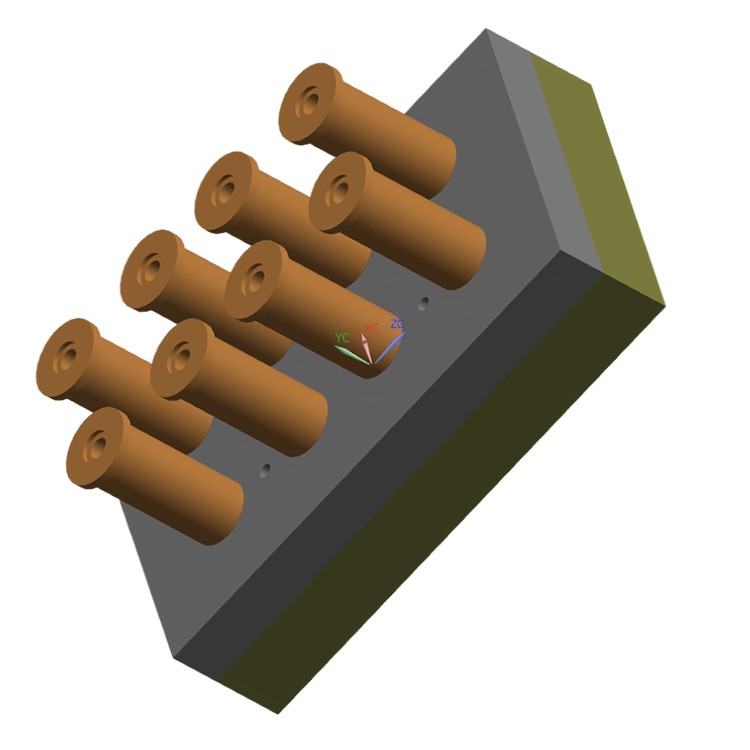

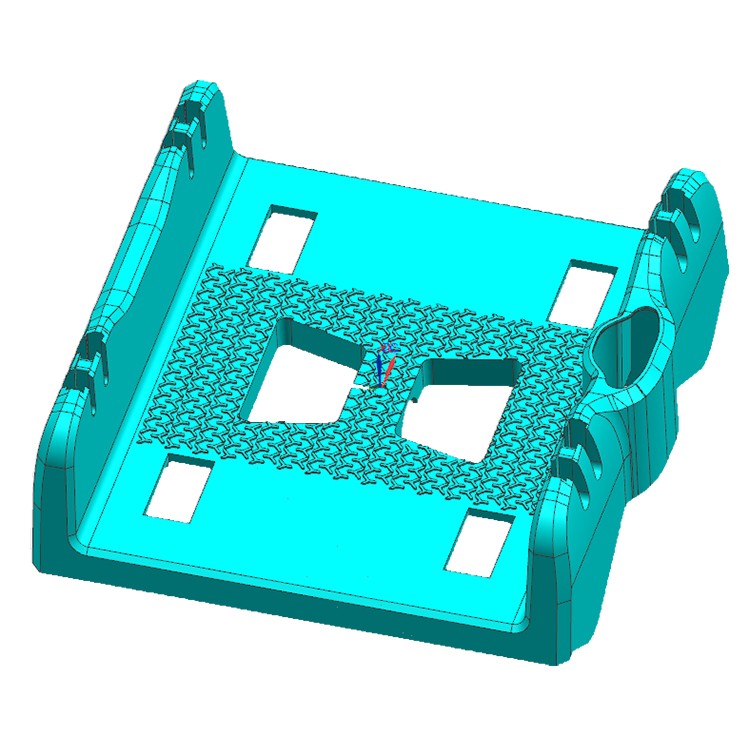

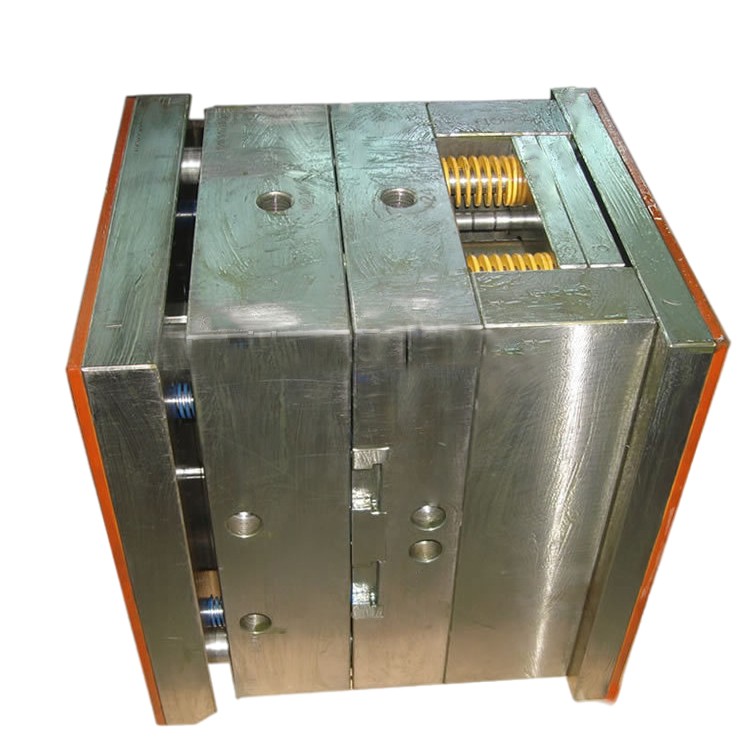

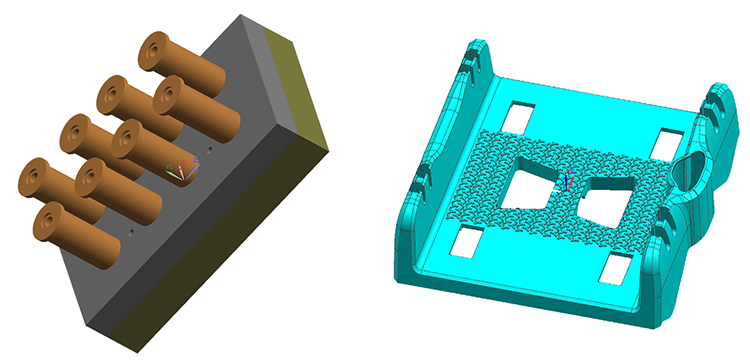

Plastic Injection Mould and Products Show:

Plastic Injection Mould Feature and Application:

The moulds we make involves house appliance, fitness equipment, electronics, industrial, auto parts, bathroom, medical, over molding and so on.

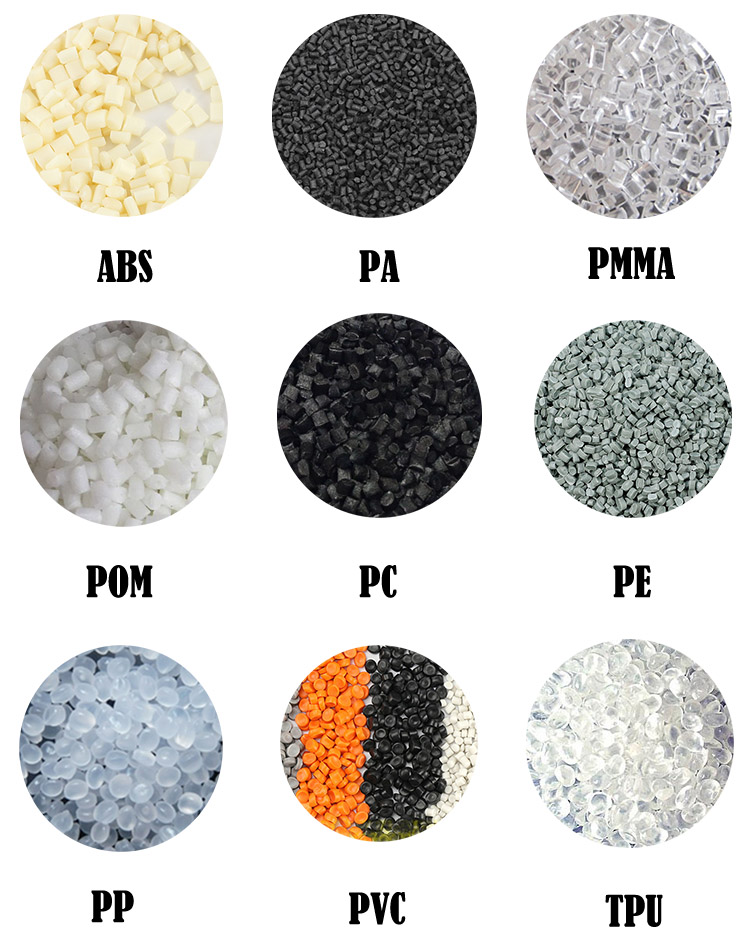

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Our Plastic Injection Mould Case Show:

Payment and Shipping:

We accept many kinds of the payment, the details as the following:

1. For the samples, we can accept PayPal, West Union and Bank Transfer as the payment, and will ship the samples by air express, such as the DHL, UPS and FEDEX.

2. For the bulk order, we can suggest the bank transfer as the payment method with the 30% deposit, we will ship out the goods according to the choice from the customers for shipping.

3. We can ensure the shipping is fast and efficient.

FAQ about Plastic Mould Manufacturing:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection. Sometimes we also make Die casting mold and stamping molds according to our customer’s requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: How long is the lead-time for a plastic injection mold?

A3: It all depends on the mold’s size and complexity. Normally, the lead time is 25_45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q4: Do you make spare parts for your customer?

A4: Yes, we will provide spare parts for the mold if needed or required by client.

Q5: How do you pack the china plastic moulds?

A5: We pack the plastic moulds with wooden box.