injection parts

-

Household Molding For Plastic Injection Parts

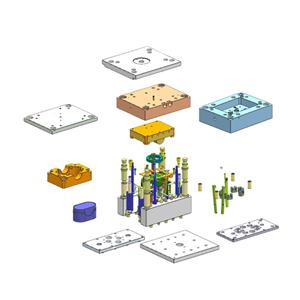

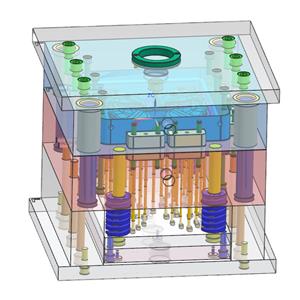

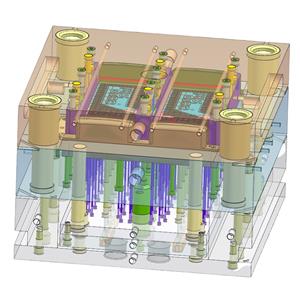

For Plastic Injection Mould: 1. Advance and enough equipment, high speed CNC, standard CNC, EDM, wire cutting, WEDM and grinder; 2. With more than 10 engineers can provide design service for plastic products and plastic injection mold, no matter 2D or 3D drawing; 3. With more than 800 sets plastic injection mold making experience since 2007; 4. Fast deliver conventional products, the lead time depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Molds are very simple and not big size, we can work out within 15 days.

Household Molding Molding for Plastic Injection Molding for Plastic Parts Household Molding Injection PartsEmail Details -

Plastic Industrial Molding For Injection Parts

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. 2. Our workshop area is about 7500 square meters; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory; 5. 3D Drawing service from plastic to plastic injection moulding tool design 6. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts.

Plastic Industrial Molding Industrial Molding Molding for Injection Parts Industrial Molding for Injection PartsEmail Details -

ABS PC PP Plastic Molded Injection Parts

Professional experience in one-stop solution on tooling and production; Satisfy the precision mold requirement in wide rage industry; Can do from mold design to manufacturing. 1. Fast Quote: With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers. 2. Mold Design and Making: Advance injection mold machine to ensure the quality; Injection mold, stamping die & die casting as well; 3. Plastic Injection Products Production: Enough and many kinds of injection machines to ensure the quantity; 4. Secondary Process: We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services; 5. After Service: For your smoothly running machine or product use.

Email Details -

Plastic Mould Custom Plastic Injection Parts

1. Have more than 15 year experience in plastic injection produce. 2. 3D Drawing service from plastic injection products design and plastic injection mould design. 3. 2 special after sales team to help you solve any problem for plastic injection parts. 4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic injection parts. 5. We have professional plastic injection mold tooling designer and advance plastic part producing line.

Email Details -

Plastic Injection Mould Parts Molding

1.Word Top Equipment: High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine from 60-950T available. 2. More Than 15 Years Mould Making and Plastic Injection: More than 800 moulds making experience and rich experience in plastic injection since the year of 2007 3. More Than 100 Staff and 5S Management Srandrad: With more than 10 engineers for design service, more than 10 managers for management and about 60 staff for production; 4. Large Square Workshop: Our workshop area is about 7500 square meters.

Plastic Injection Mould Parts Plastic Injection Parts Molding Injection Mould Parts Molding Plastic Mould Parts MoldingEmail Details -

Custom Made ABS Injection Plastic Parts

Plastic mold and plastic injection services are including: 1. Plastic product and plastic injection mold design and development, both ODM and OEM; 2. Scanning data: Get 3D drawing if you only offer the sample for plastic injection mold making; 3. Drawing re-construction; 4. Prototype making; 5. Tooling/Mold setup and trial shot; 6. Injection molding for the plastic parts. 7. Mass production

Injection Plastic Parts ABS Injection Plastic Parts Custom Injection Plastic Parts ABS Injection PartsEmail Details -

Custom Plastic Injection Parts Mould For Sport Equipment

1. Durable and long service life 50k-500k shots, according to the requirement of the products and the raw material; 2. Quick maintenance to keep the mold clean and neat Do mold maintenance to sure the plastic mold clean and neat; There are three points that is important to plastic injection maintenance: First, daily maintenance: For all kinds of moving parts, such as, ejector pin, slide, guiding post, oil for guiding bush, mould surface cleaning and water line dredging that must maintain everyday when producing; Second, regular maintenance: Beside the daily maintenance, the regular maintenance includes the cleaning of the exhaust slot the air trapped and the black level and the exhaust, and the correction of damage and wear parts etc. Third, appearance maintenance: Painting outside of the plastic injection mould to avoid rust. When lowering the plastic injection mould, the fixed and movable mould must be coated with anti-rust oil. The mold must be closed tightly to prevent dust going to the cavity.

Custom Plastic Injection Parts Mould Custom Injection Parts Mould Custom Plastic Parts Mould Plastic Mould for Sport EquipmentEmail Details -

Plastic Fitness Equipment Injection Parts Mould

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. 2. Our workshop area is about 7500 square meters; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;

Plastic Fitness Equipment Mould Plastic Fitness Equipment Injection Mould Plastic Injection Parts Mould Fitness Equipment Injection MouldEmail Details -

Automobile Moulds Plastic Injection Parts

We have our own molds plant. Our mold engineers have skill of using UG, Pro/e, SolidWorks, CAD and other 3D design software to design the molds. We have Large CNC machining centers, CNC engraving machines, EDM spark molding machines and Line cutting machines etc to produce the molds. We manufacture and export Custom Plastic Products to USA, Canada and European countries used for vary applications of Household, fitness equipment, Industrial, Auto, Electronics and Construction etc.

Email Details