plastic injection

-

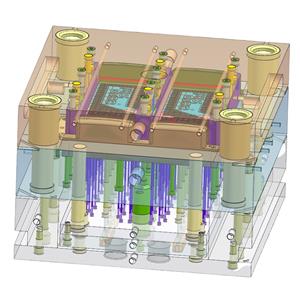

Custom Plastic Injection Parts Mould For Sport Equipment

1. Durable and long service life 50k-500k shots, according to the requirement of the products and the raw material; 2. Quick maintenance to keep the mold clean and neat Do mold maintenance to sure the plastic mold clean and neat; There are three points that is important to plastic injection maintenance: First, daily maintenance: For all kinds of moving parts, such as, ejector pin, slide, guiding post, oil for guiding bush, mould surface cleaning and water line dredging that must maintain everyday when producing; Second, regular maintenance: Beside the daily maintenance, the regular maintenance includes the cleaning of the exhaust slot the air trapped and the black level and the exhaust, and the correction of damage and wear parts etc. Third, appearance maintenance: Painting outside of the plastic injection mould to avoid rust. When lowering the plastic injection mould, the fixed and movable mould must be coated with anti-rust oil. The mold must be closed tightly to prevent dust going to the cavity.

Custom Plastic Injection Parts Mould Custom Injection Parts Mould Custom Plastic Parts Mould Plastic Mould for Sport EquipmentEmail Details -

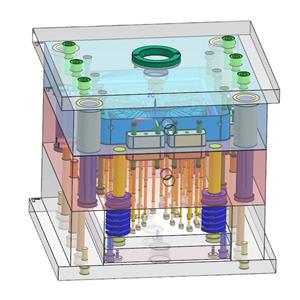

Fitness Equipment Spare Parts Plastic Injection Mold

1. Start from part design analysis; 2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making; 3. If product is complex, moldflow report will be present as well; 4. In house mold making shop ensure you mold quality under well control; 5. Normally it takes 20-40 days to make mold, precise time depends on part design; 6. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 7. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 8. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Spare Parts Plastic Mold Spare Parts Injection Mold Spare Parts Plastic Injection Mold Fitness Equipment Spare Parts MoldEmail Details -

Plastic Fitness Equipment Injection Parts Mould

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. 2. Our workshop area is about 7500 square meters; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;

Plastic Fitness Equipment Mould Plastic Fitness Equipment Injection Mould Plastic Injection Parts Mould Fitness Equipment Injection MouldEmail Details -

Fitness Equipment Plastic Cover Injection Mould

1. Provides service of part design, prototype making, mold design, mold production, mass production and assembly service in house. We are cooperating with many clients all over the world and have a deep understanding of the mold industry, our experience range from simple design to challenging technical parts; 2. Our service also covers in making CNC prototypes, die casting, injection mold with production; And sandblasting, painting, anodizing, electroplating, high polishing and laser etching also can be finished well.

Plastic Cover Injection Mould Plastic Cover Mould Fitness Plastic Cover Injection Mould Fitness Plastic Injection MouldEmail Details -

Precision Mould For Plastic Injection Products

1. Professional design/engineering/manufacturer/Service: Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services; 2. Manufacturer: over 15 years production experience: more than 15years experience for plastic injection and developing capability and more than 800 moulds making experience 3. Low Price, High quality, Durable, Fast Delivery; We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment, more than 10 engineers and about 7500 square meters workshop area.

Mould for Plastic Injection Mould for Plastic Injection Products Precision Mould for Plastic Precision Mould for Plastic ProductsEmail Details -

Custom Plastic Injection Mould For Plastic Products

1. One-stop Solution: Can provide one-stop service from mold design, mold making, machining, surface, injection production, screen printing, spray paint, assembly, packing to shipping; 2. Quality Guarantee: We have a professional team and strict quality management system to control the quality. And experienced engineers, precision machines, CMM and closed-loop QC system; 3. Customer Service: With more than 10 engineers for mold design, programming and project managers. We are using CAD/CAE/CAM software to do the design, analysis & programming.And every client is served by a specialized sales for timely technical support and after-sales service.

Custom Plastic Injection Mould Mould for Plastic Products Custom Mould Custom Mould for Plastic ProductsEmail Details -

Multi Color Plastic Injection Mould Overmolding

1. Professional experience in one-stop solution on tooling and production; 2. Satisfy the precision mold requirement in wide rage industry; 3. Can do from mold design to manufacturing.

Overmolding Plastic Injection Mould Overmolding Multi Color Mould Overmolding Multi Color Injection OvermoldingEmail Details -

Plastic Injection Insert Overmolding Mould

1. Overmolding takes a part and then overlays another layer of plastic injection molding material over it. One example would be taking a plastic handle and overmolding a soft silicone grip; 2. OEM&ODM projects are highly welcomed, we have strong R&D team, can help modify drawings; 3. The order will be produced exactly according to order details and proofed samples, our QC will submit inspection report before shipment; 4. Over Plastic – It's possible to overmold plastic onto plastic. First the primary, more rigid plastic component is molded and then the more durable plastic is molded over the previous plastic part.

Overmolding Mould Injection Overmolding Mould Plastic Overmolding Mould Plastic Injection Overmolding MouldEmail Details -

Two Color Plastic Injection Overmolding

1. Plastic injection mould design and making service and plastic injection service for over 30 countries; 2. Provide high-volume injection molding solutions; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly 4. 4. Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 5. Fast delivery, if the sample plastic injection mould, we can finish in 10days; 6. More than 800 mould making experience;

Injection Overmolding Two Color Plastic Overmolding Two Color Overmolding Two Color Plastic Injection OvermoldingEmail Details