plastic injection

-

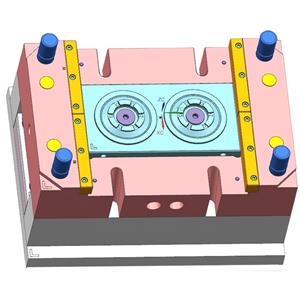

Universal Plastic Injection Mould For Plastic Products

(1) Use the brand material, like "Mitsubishi" to make sure the quality. (2) 10 Lines with Big capacity-cost-effective and flexible to adjust production for volume and urgent orders. (3) Strict QC during producing to control the quality. (4) Choose high precision mold and advance plastic injection machine to make sure the high glossy and stable quality, high optical polished surface quality, low surface roughness average, thickness tolerance control is good. (5) 15-year factory experienced in plastic mold and plastic injection and with strong customization capacity, satisfy your requirement to the best.

Mould for Plastic Products Universal Mould Universal Plastic Injection Mould Universal Injection Mould for Plastic ProductsEmail Details -

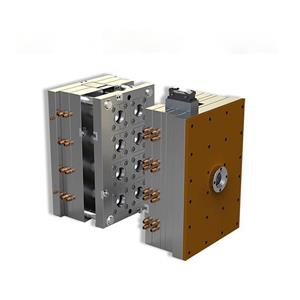

Precision Custom Plastic Injection Mould

1). Quickly response and complete understanding 2). The most competitive and reasonalbe price 3). Short delivery time and prompt delivery 4). Well and High Quality Control 5). Customer's Designs and Logos are welcome 6). Enough and advance machines and equipments.

Precision Custom Mold Precision Plastic Injection Mold Precision Custom Plastic Mold Precision Custom Plastic Injection MoldEmail Details -

Custom Universal Plastic Injection Mould

1. Industrial design and full engineering support; 2. Provide OEM & ODM and assembling services; 3. All of raw material are high quality; 4. Continually upgrading and advancing our equipment to remain the competitive; 5. Ensure customer drawing privacy, protect the customer's market; 6. Samples will be finished within 3 days; 7. 100% inspection before shipping.

Custom Universal Mould Custom Universal Plastic Mould Custom Universal Injection Mould Universal Injection MouldEmail Details -

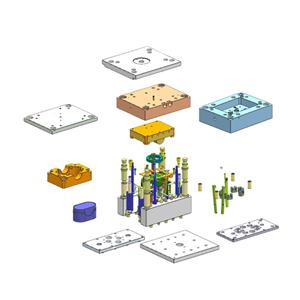

Custom Precision Molding Plastic Injection Mould

Project Evaluation; Product Design; Electronic Design & Engineering; Mechanical Design & Engineering; Prototype Design & Engineering; Design for Manufacturing; Manufacturing Coordination; Mould design; Manufacturing; Second processing; Assembly and etc., One-stop services for plastic parts. More than 15 years experience

Molding Plastic Injection mould Precision Molding Custom Precision Molding Custom Precision Plastic Injection mouldEmail Details -

Multi Or Single Cavity Plastic Parts Injection Molding

We continually works on development and improvement for holding the management tenets of integrity, Quality first and Credit Tops. By far, We are in possession of one lot advanced equipment and one excellent team. Our Products have already been setup good relationship with many domestic and oversea clients, We serve for customers with advanced technology, good quality, reasonable price and considerate after sale service, Our products are famous and get good reputation in both domestic market and oversea market.

Email Details -

Plastic Injection Molding For Spare Parts

For Plastic Injection Mould: 1. High quality raw material to ensure the high quality of the plastic injection mould; 2. Fast delivery, if the sample plastic injection mould, we can finish in 10days; 3. More than 800 mould making experience; 4. Can offer plastic injection making and injection plastic parts, silk screen print and spray paint one stop service. For Plastic Injection Products: 1. Advance injection machine to ensure the quality; 2. Enough and many kinds of injection machines to ensure the quantity; 3. High productivity;

Email Details -

Household Molding For Plastic Injection Parts

For Plastic Injection Mould: 1. Advance and enough equipment, high speed CNC, standard CNC, EDM, wire cutting, WEDM and grinder; 2. With more than 10 engineers can provide design service for plastic products and plastic injection mold, no matter 2D or 3D drawing; 3. With more than 800 sets plastic injection mold making experience since 2007; 4. Fast deliver conventional products, the lead time depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Molds are very simple and not big size, we can work out within 15 days.

Household Molding Molding for Plastic Injection Molding for Plastic Parts Household Molding Injection PartsEmail Details -

Medical Plastic Products Injection Mold

1. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 2. With more than 20 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers. 3. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 4. advance Equipment-imported sophisticated production and testing equipment with high stability.

Email Details -

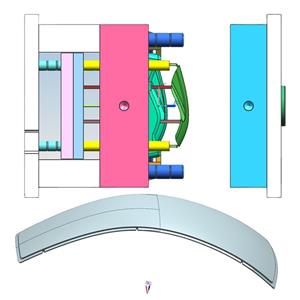

OEM Plastic Injection Auto Parts Mould

For Plastic Injection Mould: 1. High quality raw material to ensure the high quality of the plastic injection mould; 2. Fast delivery, if the sample plastic injection mould, we can finish in 10days; 3. More than 800 mould making experience; 4. Can offer one stop service from design, plastic injection making and injection plastic parts, silk screen print and spray paint . For Plastic Injection Products: 1. More than 50 advance injection machines to ensure the quality; 2. From 60T to 950T plastic injection machines to ensure the quantity;

Plastic Injection Auto Parts Mould Injection Auto Parts Mould Plastic Auto Parts Mould OEM Plastic Parts MouldEmail Details