Custom Universal Plastic Injection Mould

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. Industrial design and full engineering support;

2. Provide OEM & ODM and assembling services;

3. All of raw material are high quality;

4. Continually upgrading and advancing our equipment to remain the competitive;

5. Ensure customer drawing privacy, protect the customer's market;

6. Samples will be finished within 3 days;

7. 100% inspection before shipping.

Custom Universal Plastic Injection Mould

Plastic Injection Mould Specification:

Product name | Custom Universal Plastic Injection Mould |

Mould base | Standard mould base, LKM, HASCO etc. |

Measuring Equipment | Digital Caliper; Digital micrometer; Internal Micrometer; Optical comparator; GO-NO-GO Gauges; Hardness Tester; Routine inspection of calipers. |

Tolerance | 0.01-0.05mm |

Hardness of Cavity & Core | 42-45HRC |

Hardness of Wear Parts | 42-48HRC |

Design software | UG, PROE, CAD, CAXA etc. |

Plastic material | ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc. |

Surface treatment | Plating, Painting, polishing, Laser engraving |

Mould life | 300,000-1,000,000 shots |

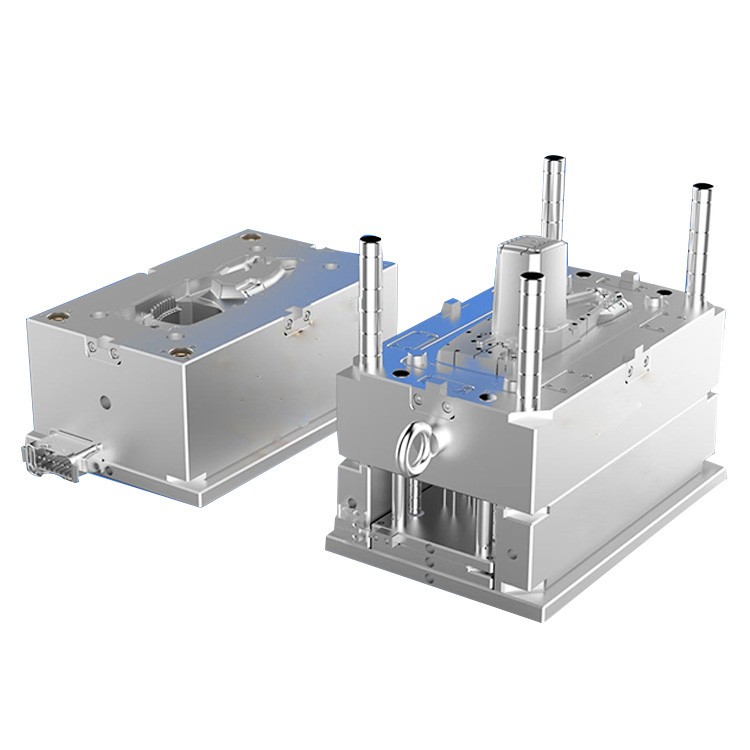

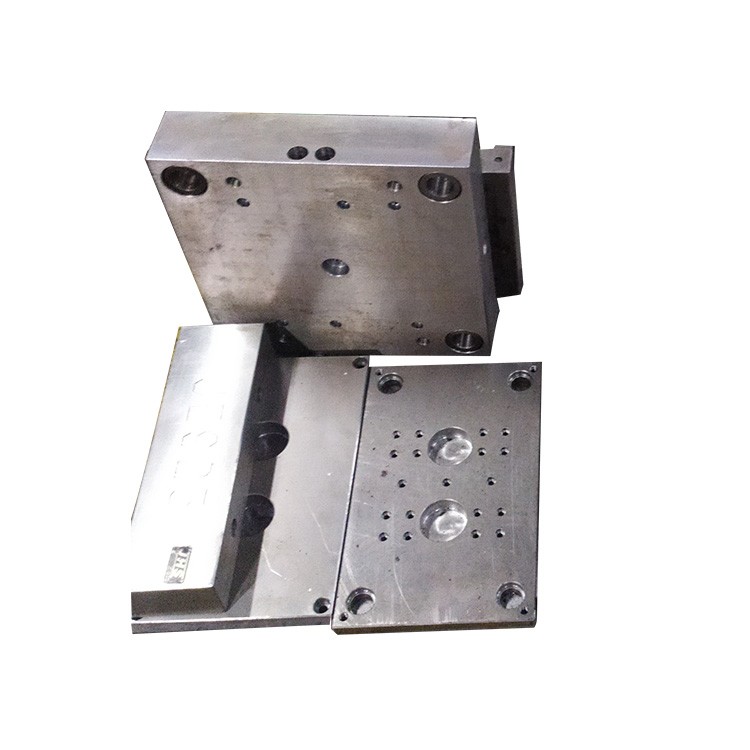

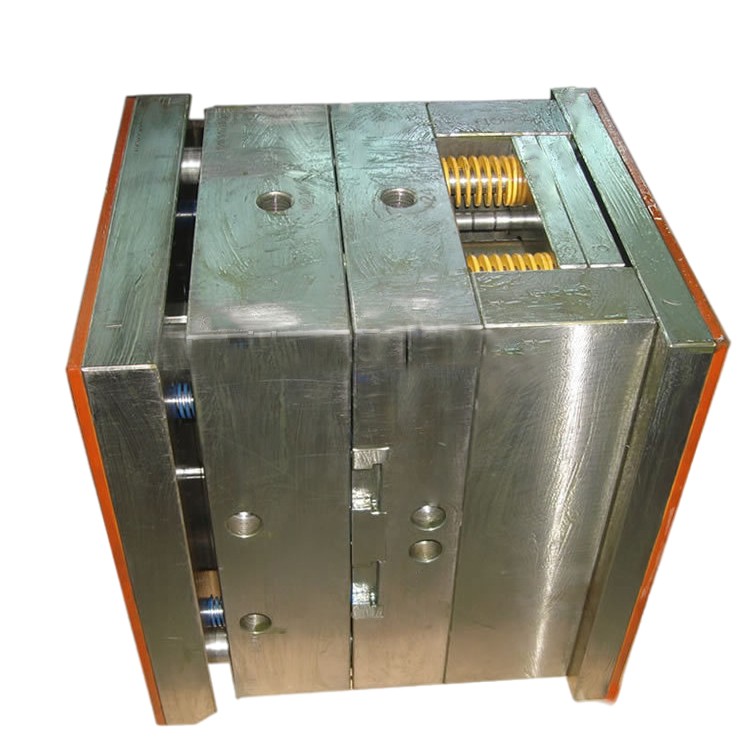

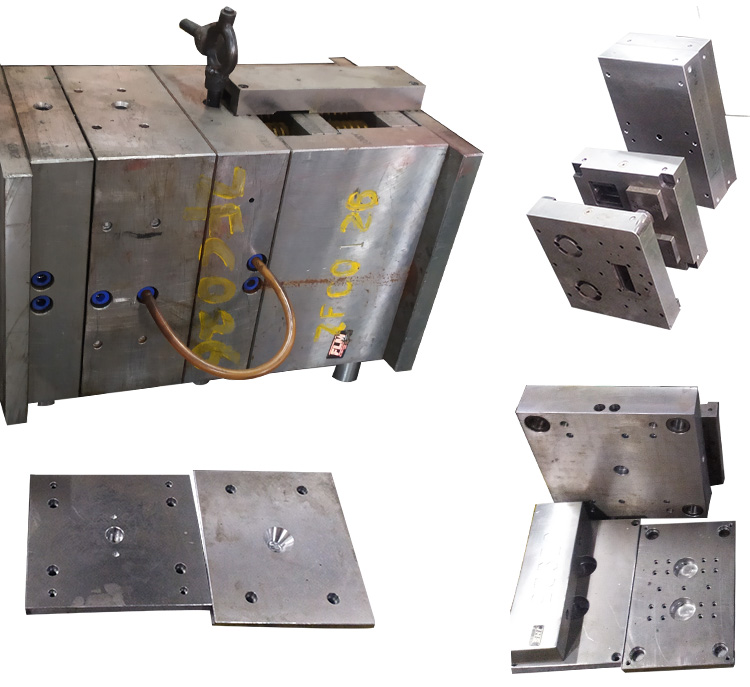

Plastic Injection Mould and Products Show:

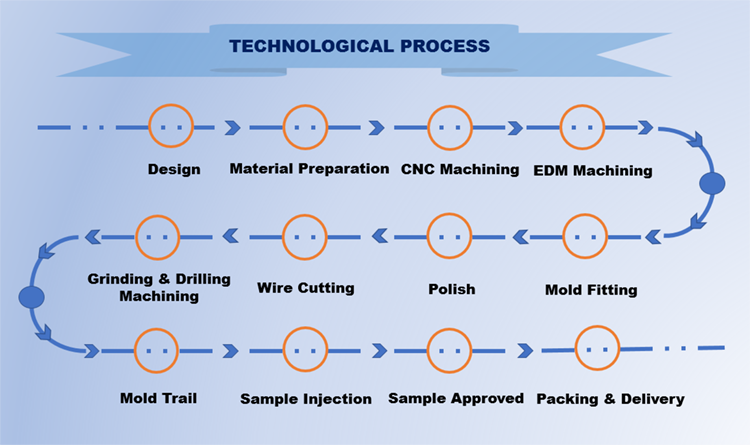

Plastic Injection Mould Feature and Application:

1. Efficiency production and automotive operation;

2. Shape can be from simple to complex, the size can be from large to small and the product size is accurate;

3. It is used in the forming and processing fields of mass production and products with complex shapes.

The moulds we make involves house appliance, fitness equipment, electronics, industrial, auto parts, bathroom, medical, over molding and so on.

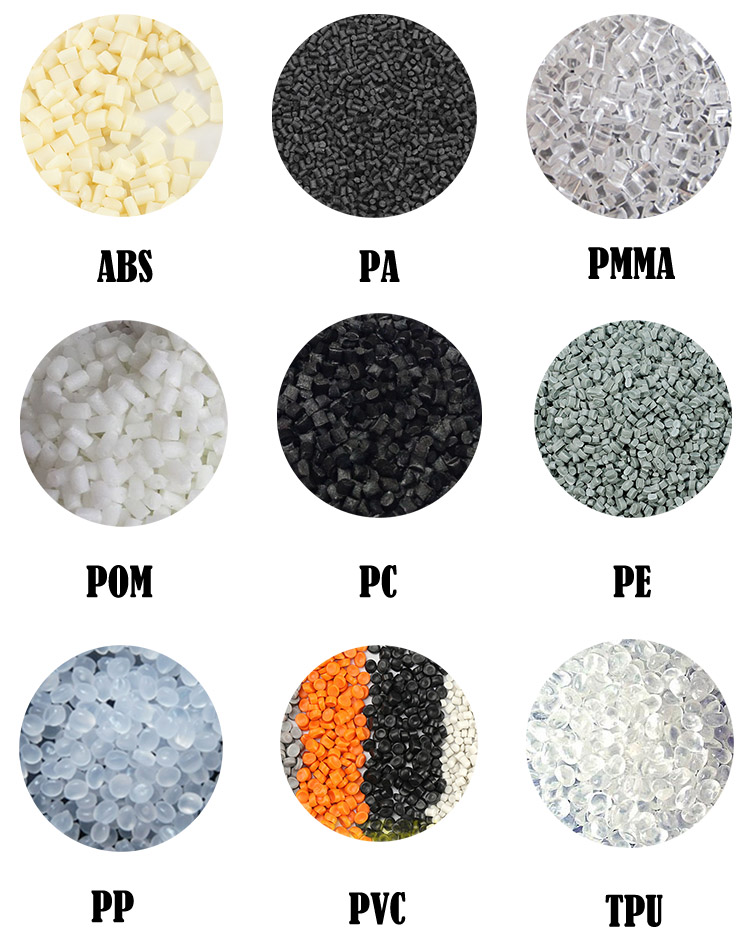

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Plastic Injection Mould Manufacturer Information:

we are a professional manufacturer of Plastic injection mould and plastic products express in plastic parts of sport equipment and plastic household products. Now we are one of the important manufacturers in sport equipment industry and plastic household industry. We also produce and sales plastic household products and plastic electronic products.

We are located in Xinglin development, Jimei district zone, Xiamen City. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. Our workshop area is about 7500 square meters and we have precision production equipment which reach the international advanced level and the experienced technician. Now our production value can reach 1.4 Billion RMB. “Quality first, continuous improvement, respect individual, team spirit” is our top management objective. We will make “build quality brand, service the needs of customers” as our guiding ideology. In connection with the requirement of domestic market and international market, we will take “excellent quality, perfect service” to meet the challenge actively to achieve our company top management goal --- continuity progress.

Our Plastic Injection Mould Case Show:

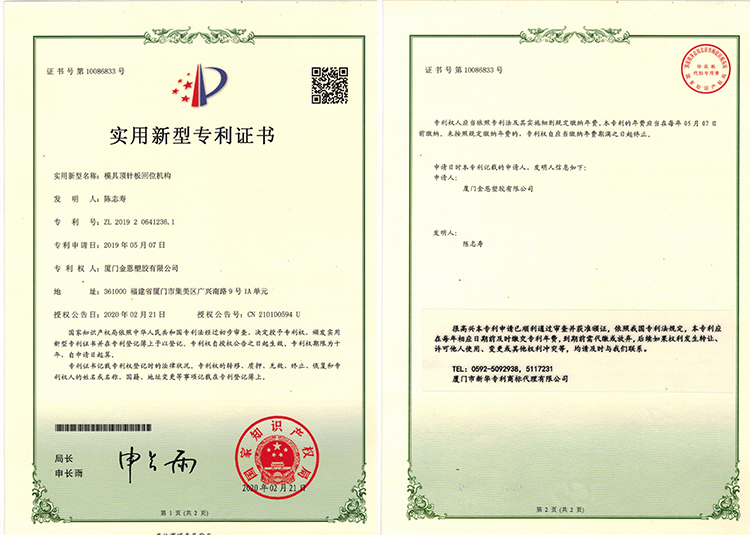

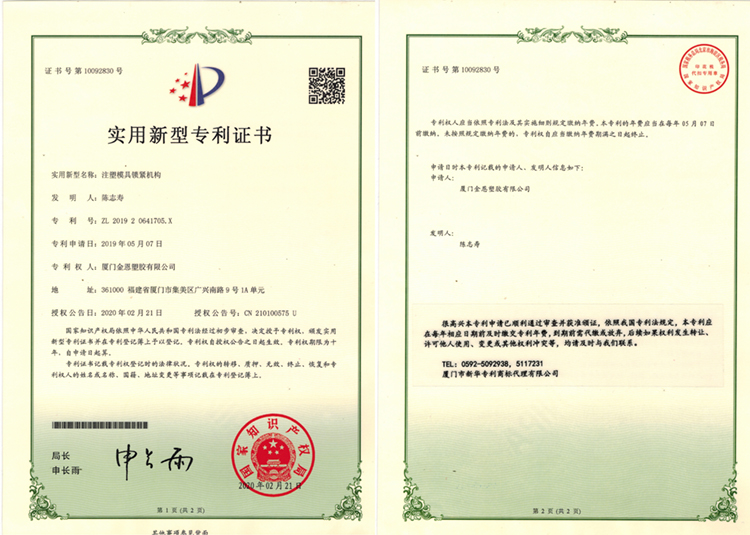

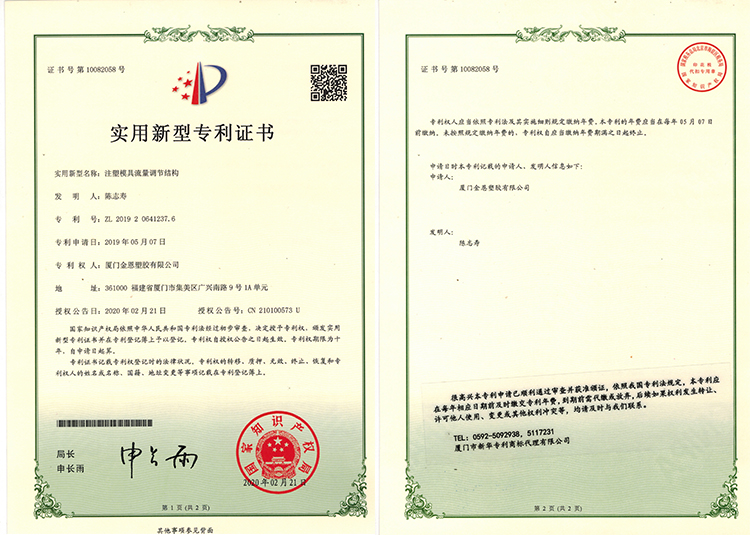

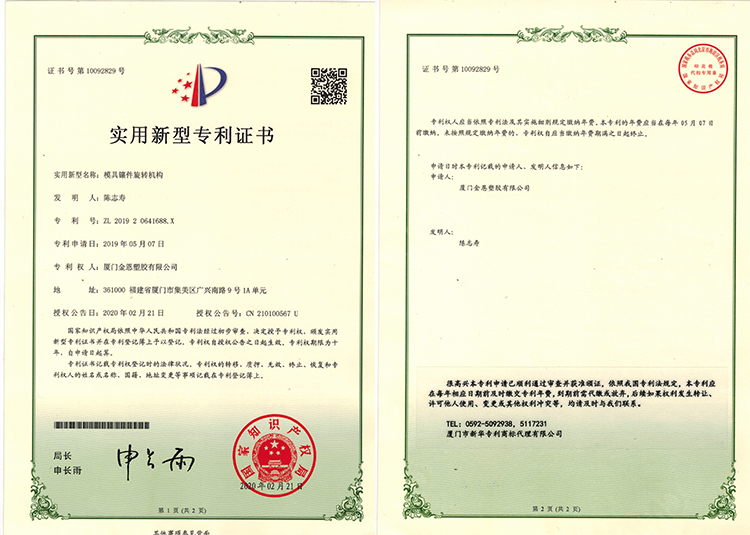

Our Certificates and Patents:

Payment and Shipping:

We accept many kinds of the payment, the details as the following:

1. For the samples, we can accept PayPal, West Union and Bank Transfer as the payment, and will ship the samples by air express, such as the DHL, UPS and FEDEX.

2. For the bulk order, we can suggest the bank transfer as the payment method with the 30% deposit, we will ship out the goods according to the choice from the customers for shipping.

3. We can ensure the shipping is fast and efficient.

FAQ about Plastic Mould Manufacturing:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection. Sometimes we also make Die casting mold and stamping molds according to our customer’s requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, we can provide steel certificate or hardness certificate to prove.

Q5: Can you make the texture / text / heat treatment /nitriding for the plastic injection mold?

A5: Yes, as plastic mold factory, we have long term cooperated subsidiary factories that do those processes. They are professional and well reputed in our local market.

Q6: How long is the lead-time for a plastic injection mold?

A6: It all depends on the mold’s size and complexity. Normally, the lead time is 25_45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q7: Do you make spare parts for your customer?

A7: Yes, we will provide spare parts for the mold if needed or required by client.

Q8: How do you pack the china plastic moulds?

A8: We pack the plastic moulds with wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any movement.