precision molding

-

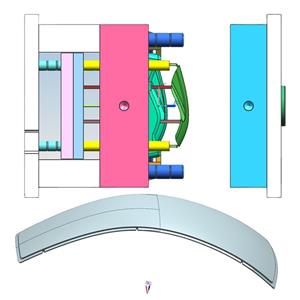

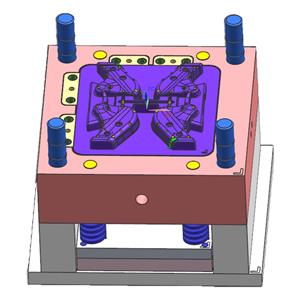

Custom Precision Molding Plastic Injection Mould

Project Evaluation; Product Design; Electronic Design & Engineering; Mechanical Design & Engineering; Prototype Design & Engineering; Design for Manufacturing; Manufacturing Coordination; Mould design; Manufacturing; Second processing; Assembly and etc., One-stop services for plastic parts. More than 15 years experience

Molding Plastic Injection mould Precision Molding Custom Precision Molding Custom Precision Plastic Injection mouldEmail Details -

Precision Injection Molding Plastic Mould

Production capacity: Our factory is working 24 hours and 28 days every month and with more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. Quality control and test: It has many times of quality check for every order, beginning from raw material check to package check. Every production line has at least two QC staff for random check and regular check. Test: manufactory testing machine includes rubber tension tester, rubber vulcanization instrument, durometer, calipers, ageing oven for Density test, Elongation at break, Bonding strength, Pulling force test, twisting force test, Rergarding other test like anti-high/low temperature which will be tested by Third Party Testing Center as customer required.

Injection Molding Plastic Injection Molding Plastic Mould Precision Injection Molding Precision Plastic MouldEmail Details