fitness equipment

-

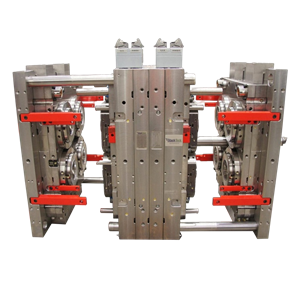

Fitness Equipment Plastic Parts Injection Moulding

Plastic Injection Mould and Services: 1. Products Designing & Manufacturing. 2. Rapid Prototyping 3. Plastic Moulds Designing & Manufacturing. 4. Plastic Injection Molding 5. Product Treatment & Product Assembling 6. OEM/ODM is welcomed.

Parts Injection Moulding Fitness Equipment Injection Moulding Fitness Injection Moulding Fitness Plastic Injection MouldingEmail Details -

Hot

Fitness Equipment Mould Plastic Injection Molding

1. We can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 2. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 3. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Email Details -

High-Precision Plastic Parts Molding

Main business: 1. Customized injection mold 2.Injection molding services 3. Production of fitness equipment parts 4. Assembly and packaging services Focus on providing customized manufacturing services based on design drawings or samples. Tip: 1. Support OEM/ODM customization! Welcome to contact us! 2. There are special offers now. You can get them by sending an inquiry 3. Support samples, if you need samples to send inquiries, please contact us

injection mold Injection molding services Production of fitness equipment parts Assembly and packaging servicesEmail Details -

Spinning Bike Pedal

1. We use ABS/HIPS material to make pedals. 2. Customer-designed LOGO patterns can be provided. 3. Color: can be customized 4. Customized appearance design: accepted 5.Service: OEM or ODM 6. Sample: Available 7. Sample fee: Buyers need to provide express fee 8. Sample delivery time: within 15 days 9. Payment method: 30% prepaid by T/T, the balance is paid before shipment 10. Production time: 7-15 days 11. Delivery port: Xiamen

Email Details -

Special Tension Control For Spinning Bikes

We are a leading enterprise engaged in the production of fitness equipment parts. We are an agent for many large sports equipment brands in China. We have more than 30 own R&D patents, including massage pedals, electronic tension control, etc. Products are mainly sold to mainland China, North America, Eastern Europe and countries in the Middle East, with more than 200 partners

Email Details -

Fitness Equipment Plastic Mold For Injection Spare Part

We can offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement. 1. In the service of plastic injection, Ideal plastic is more than just an injection molder. 2. We provide solutions to manufacturing from start to finish. 3. Our expertise enables us to provide clients with superior product by providing the highest quality in design, development, and solutions for precision injection molding and related manufacturing. 4. We have over 15 years production experience. 5. Have more than 50 plastic injection mold machines, variety of precision mold produce equipment and spray printing equipment and more than 7500 square meters workshop.

Fitness Equipment Plastic Mold Plastic Mold for Spare Part Plastic Mold for Injection Spare Part Mold for Injection Spare PartEmail Details -

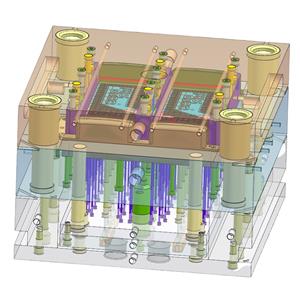

Fitness Equipment Spare Parts Plastic Injection Mold

1. Start from part design analysis; 2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making; 3. If product is complex, moldflow report will be present as well; 4. In house mold making shop ensure you mold quality under well control; 5. Normally it takes 20-40 days to make mold, precise time depends on part design; 6. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 7. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 8. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Spare Parts Plastic Mold Spare Parts Injection Mold Spare Parts Plastic Injection Mold Fitness Equipment Spare Parts MoldEmail Details -

Plastic Fitness Equipment Injection Parts Mould

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. 2. Our workshop area is about 7500 square meters; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;

Plastic Fitness Equipment Mould Plastic Fitness Equipment Injection Mould Plastic Injection Parts Mould Fitness Equipment Injection MouldEmail Details