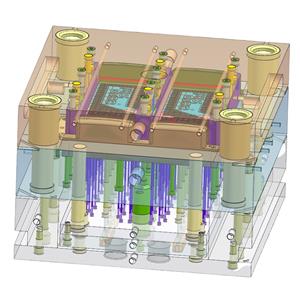

injection parts mould

-

Plastic Injection Parts Mold For Bathroom Shower

1. We have our own tooling shop, equipped with advanced machines for plastic injection mould and the plastic injection products. 2. We also have their own injection shop, to run the mold test & mass production for customers. 3. We have more than 15years experience for plastic injection mould and plastic injection. 4. We have precision production equipment which reach the international advanced level and the experienced technician. 5. ISO 9001 Certified for all of our plastic injection mould and plastic injection products and our factory;

Email Details -

Custom Plastic Injection Parts Mould For Sport Equipment

1. Durable and long service life 50k-500k shots, according to the requirement of the products and the raw material; 2. Quick maintenance to keep the mold clean and neat Do mold maintenance to sure the plastic mold clean and neat; There are three points that is important to plastic injection maintenance: First, daily maintenance: For all kinds of moving parts, such as, ejector pin, slide, guiding post, oil for guiding bush, mould surface cleaning and water line dredging that must maintain everyday when producing; Second, regular maintenance: Beside the daily maintenance, the regular maintenance includes the cleaning of the exhaust slot the air trapped and the black level and the exhaust, and the correction of damage and wear parts etc. Third, appearance maintenance: Painting outside of the plastic injection mould to avoid rust. When lowering the plastic injection mould, the fixed and movable mould must be coated with anti-rust oil. The mold must be closed tightly to prevent dust going to the cavity.

Custom Plastic Injection Parts Mould Custom Injection Parts Mould Custom Plastic Parts Mould Plastic Mould for Sport EquipmentEmail Details -

Plastic Fitness Equipment Injection Parts Mould

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. 2. Our workshop area is about 7500 square meters; 3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;

Plastic Fitness Equipment Mould Plastic Fitness Equipment Injection Mould Plastic Injection Parts Mould Fitness Equipment Injection MouldEmail Details