Beauty Instrument Shell Molding

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. Have experience for mould

2. 3D Drawing service from plastic to plastic injection moulding tool design

3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts.

4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts.

5. We have professional plastic injection mold tooling designer and plastic part producing line.

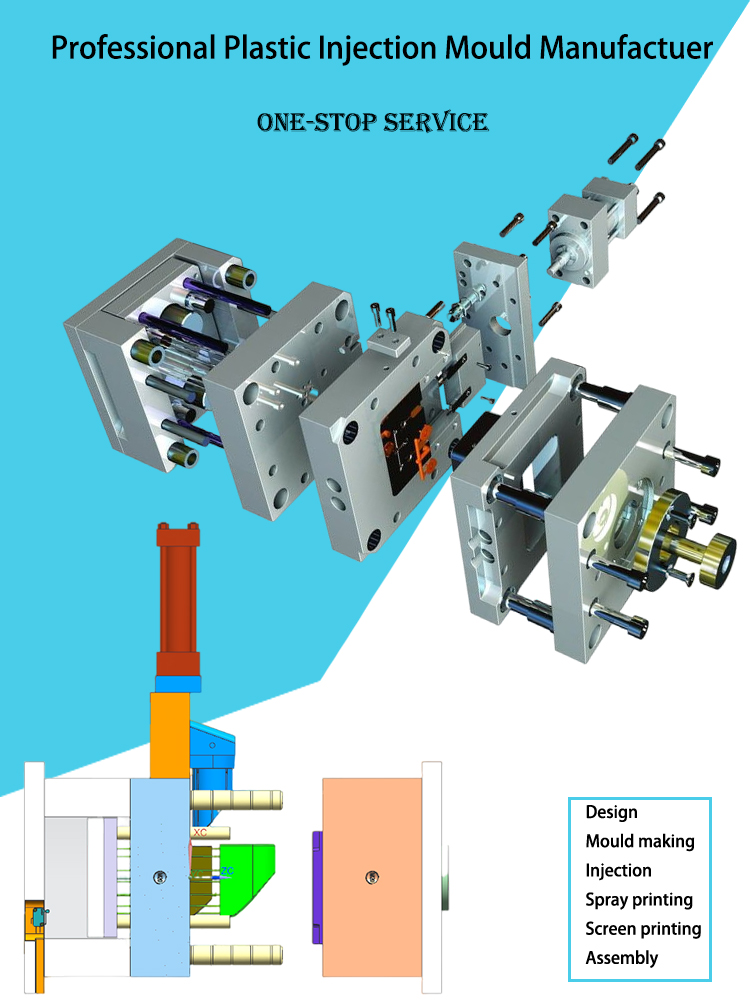

6. Plastic Injection Mould OEM & ODM Services

Plastic Injection Parts Electronics Products Mould

Plastic Electronics Mould Information:

Plastic Electronics Mould Information:

| Product type: | Plastic injection mould for elecrtonics parts |

| Mould material: | P20,NAK80, S136, 718H, etc.(Hardness 35~55HRC) |

| Cavity: | Multi cavities , single cavity |

| Runner: | Hot runner or cold runner |

| Ejection system: | Motor/hydraulic cylinder/stripping plate/angle pin,etc |

| Design software: | UG, PROE, CAD, CAXA ect. |

| Surface treatment: | Polish,texture,sandblasting,chrome |

| Mould life: | 300,000~ 1,000,000 shots |

| Delivery time: | 25~30 days for delivey T1 samples, depands on product instruction. |

| Plastic material: | ABS,PP,POM,PC, PMMA, PA and so on |

Our Services:

Plastic Electronics Mould Manufacturer Information:

Packing and Delivery:

FAQ:

Q1:How can I get the sample to check your quality?

A1:After price confirmation, you can require for samples to check our product's quality.

A2:We usually quote within 24 hours after we get the enough infomation of the products.

Q3: What is your term of delivery?

A3: We accept EXW, FOB Xiamen. You can choose the one which is the most convenient or cost effective for you.Q4: What about the lead time?

A4: It depends on the order quantity and the season you place the order.

Q5: What is the quality control of your company?

A5: Our company has the system certification of ISO9001. We have special product measurement room, and have very professional testing & measuring equipment. We do raw material incoming inspection, in-process product quality control and outgoing goods quality control.