Storage Box Plastic Molding

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. One-stop Service:

Support plastic injection mold design, plastic injection mold making, plastic injection, assembly work service, , silk screen print, paint , spary printing and packaging services;

2. Rich Experience:

With more than 800 sets plastic injection mold design and making and more than 15years experience in plastic injection plastic injection and developing capability;

3. Advance and enough Equipment:

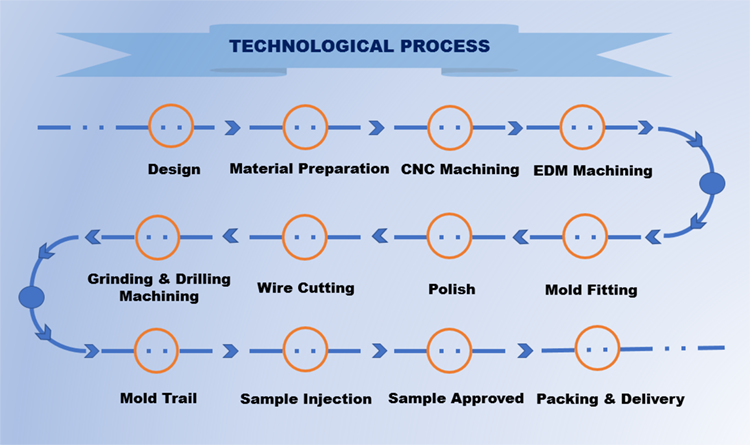

Advance and enough injection machines to ensure the quality and quantity, the machine we have: High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Machines from 60-950T available.

Custom Injection Plastic Household Mold

Plastic Households Mould Specification:

Mould Base | DME, SD, LKM, HASCO and so on |

Mold Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Drawing Format | step, dwg, igs, pdf |

Mold Life | 50K-1.5Million Shots |

Runner System | Hot runner/Cold runner or combined |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 60 to 950ton plastic injection machines |

Plasitc Material | PA6, PA66, ASA, POM, PPS, ABS, ABS+GF, ABS/PC, POM(Derlin), PP, PE, PC, PMMA(Acrylic), PVC, PEI, PBT, PTF etc. |

Surface Treatmetn | Matte, glossy, textured, smooth |

Product Name | Custom Injection Plastic Household Mold |

Plastic Households Mould Picture:

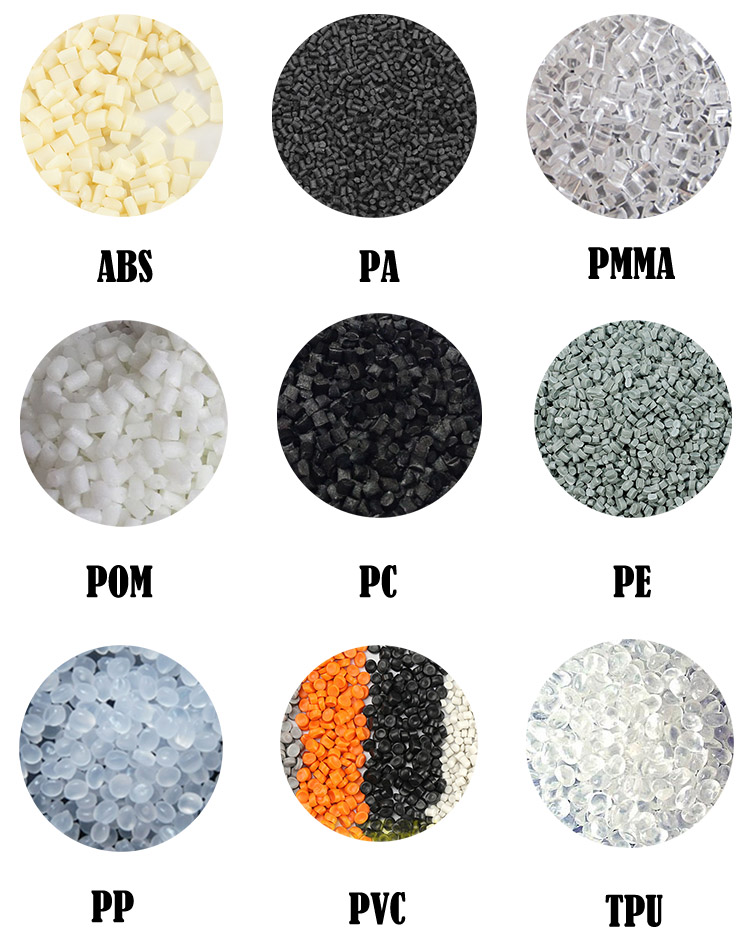

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Product Qualification and Certificate:

FAQ:

Q: How can I get the quotation?

A: We will submit the quotation in 24 hours if getting detailed information during working days. If you can provide us the following information together with your inquiry, it will help us quotated fast and efficiently.

1) 3D Step of Files and 2D Drawings, if do not have the drawing, offer us the samples, or detail information about the sample such as, its size and weight;

2) Product material;

3) Product surface treatment

4) Quantity

5) Other demands or requirements, such as packing, labels,delivery,etc.

Q: How you do the quality control?

A:

1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out.

Q: How long is the lead-time for a plastic injection mold?

A: It all depends on the mold's size and complexity. Normally, the lead time is 25-45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.