injection plastic

-

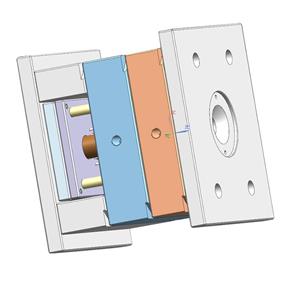

Homeware Injection Molding Plastic Mould

1) We are a professional OEM&ODM plastic injection mold manufacturer; 2) We have a team with experienced engineers and quality control team as our strong backing; 3) High quality, competitive price, quick response; 4) Professional technical support; 5) Quick response; 6) A strict quality control process; 7) High-cost performance; 8) More than 15 years experience in plastic injection mold and plastic injection; 9) ISO/ERP system guarantee.

Homeware Injection Molding Homeware Molding Homeware Injection Molding Plastic Mould Homeware Injection Plastic MouldEmail Details -

Molding Injection Plastic Parts Mould

We have professional engineering team which has more than 10 engineers who is good at plastic injection mold design, we can offer one stop service from drawing design, tools & samples manufacturing, mass productions, packing till shipment. Our sales team are thoughtful and good at understanding your idea and points, where help to make your work much eaiser. 24*7 comminication service, whenever you need us, we are here for you. Advance and enough injection machines to ensure the quality and quantity, the machine we have: High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Machines from 60-950T available.

Molding Injection Molding Injection Plastic Parts Molding Injection Plastic Parts Mould Plastic Parts MouldEmail Details -

Injection Mold Bathroom Plastic Mold

1. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 2. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 3. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. 4. With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

Email Details -

Precision Injection Plastic Households Mould

1. Have experience for more than 800 moulds 2. 3D Drawing service from plastic product desgign to plastic injection moulding tool design 3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and plastic injection parts. 4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts. 5. We have more than 10 professional plastic injection mold tooling designer and advance plastic part producing line. 6. ISO 9001, ISO 14001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory

Households Mould Injection Plastic Housewares Mould Precision Housewares Mould Precision Injection Housewares MouldEmail Details -

Customzied Injection Cover Plastic Moulding

1. Free Part Design:Sending us sample we can provide free part design work.We also provide free mold design work; 2. Free Mold Design:After order confirmed,mold design work is free of charge; 3. Free Mold:For quantity more than 100000pcs per order,mold is free of charge; 4. Fast Mold:For simple and urgent mold,we promise can speed up to 15 days to finish mold and send out samples; 5. One-stop service from plastic injection mould making to plastic injection and assembly;

Email Details -

Plastic Injection Service Injection Plastic Product

1. We have our own tooling shop, equipped with advanced machines for plastic injection mould and the plastic injection products. 2. We also have their own injection shop, to run the mold test & mass production for customers. 3. We have more than 15years experience for plastic injection mould and plastic injection. 4. We have precision production equipment which reach the international advanced level and the experienced technician. 5. ISO 9001 Certified for all of our plastic injection mould and plastic injection products and our factory;

Email Details -

Plastic Cover Mould Injection Plastic Molding

1. 7500 square meters factory mainly provides CNC machining service and plastic injection service. 2. ISO certificated,supports third-party verification. 3. Fast deliver conventional products, the lead time depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days. 4. Engineering service provided, with more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

Mould Injection Plastic Plastic Cover Molding Mould Injection Plastic Molding Plastic Cover Injection MoldingEmail Details -

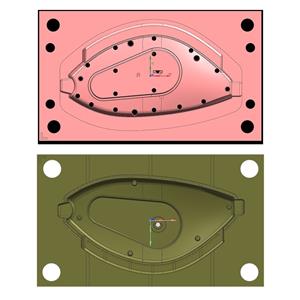

Precision Injection Molding Plastic Products

We have a professional engineers design team with more than people and can use CAD, Pro-E, UG, Solidworks etc. to ensure all kinds of design.Before the project started: 1. If you have 3D STEP/IGES/X_T drawing or 2D drawing, please send it to us before quotation, then we will do DFM and mould design for you. 2. If you only have samples please provide us the samples, we can design 3D drawing for you and quotation. We have enough and advance equipment and machines, such as high CNC and other equipment for plastic mold making, 60 to 950T plastic injection machines for the plastic mold, assembly line for spray print and other machine for us to provide the one-stop service.

Precision Plastic Products Injection Molding Plastic Products Injection Plastic Products Precision Injection ProductsEmail Details -

Custom Made ABS Injection Plastic Parts

Plastic mold and plastic injection services are including: 1. Plastic product and plastic injection mold design and development, both ODM and OEM; 2. Scanning data: Get 3D drawing if you only offer the sample for plastic injection mold making; 3. Drawing re-construction; 4. Prototype making; 5. Tooling/Mold setup and trial shot; 6. Injection molding for the plastic parts. 7. Mass production

Injection Plastic Parts ABS Injection Plastic Parts Custom Injection Plastic Parts ABS Injection PartsEmail Details