Plastic classification and 7 grades of plastics

levels of plastics

In daily life, careful friends may find that there are small triangular signs engraved on the bottom of plastic containers, and numbers ranging from 1 to 7 are engraved inside the triangular frame. You know what specifications are represented behind each number. Plastic container? I’ll explain it to you one by one below.

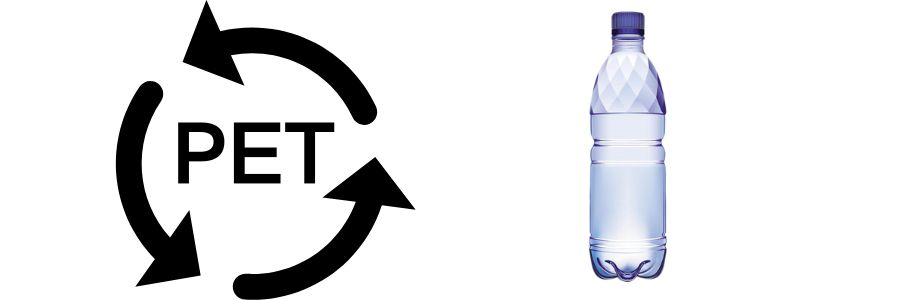

01—PET (polyethylene terephthalate)

Common uses of polyethylene terephthalate: mineral water bottles, carbonated beverage bottle packaging, etc.Polyethylene terephthalate is a common resin in life. It has good mechanical properties. The impact strength is 3 to 5 times that of other films. It has good folding resistance, high transparency, can block ultraviolet rays, and has good gloss. . Transparent plastic bottles made of it are often called "plastic bottles". This kind of plastic usually has a maximum heat resistance of 65°C and a minimum cold resistance of -20°C. Therefore, it is generally only suitable for holding normal temperature liquids or low temperature liquids. If it contains high-temperature liquid or directly heats it, thermal deformation will easily occur and substances harmful to the human body will be produced. Moreover, scientists have found that long-term use of this plastic product for more than 10 months may release carcinogens that are toxic to the human body. Therefore, these plastic bottles should be sorted and thrown away immediately after use. They should not be used as water cups, and try not to use them as storage containers to hold other items, so as not to cause health problems and cause more harm than good.

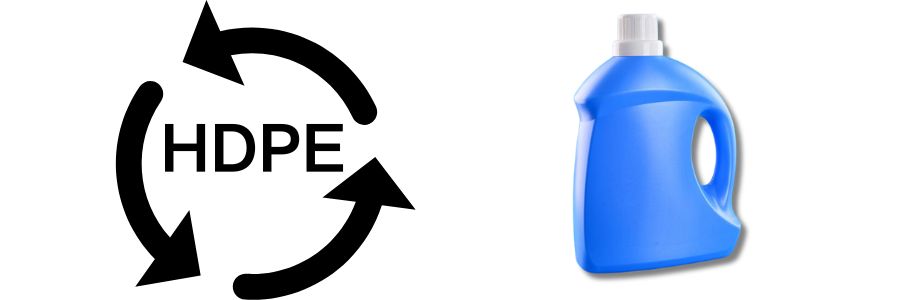

02—HDPE (high density polyethylene)

Common uses of high-density polyethylene: cleaning supplies, bath products, white medicine bottles, plastic containers for skin care products, and the plastic bags currently used in supermarkets.High-density polyethylene is a highly crystalline, non-polar thermoplastic resin with a melting temperature between 120 and 160°C. The general use temperature should be controlled within 100°C. Among industrial products, it can withstand up to 110°C. At high temperatures of ℃, if plastic bags marked for food can be used to contain food. Plastic containers that hold cleaning products and bath products can be reused after a small self-cleaning period. However, these containers are usually difficult to clean and retain the original cleaning products, becoming a breeding ground for bacteria and causing incomplete cleaning. Therefore, in daily life, it is best not to recycle products made of high-density polyethylene. They should be replaced on time and in a timely manner. Waste products should be recycled and sorted to prevent environmental pollution and secondary pollution.

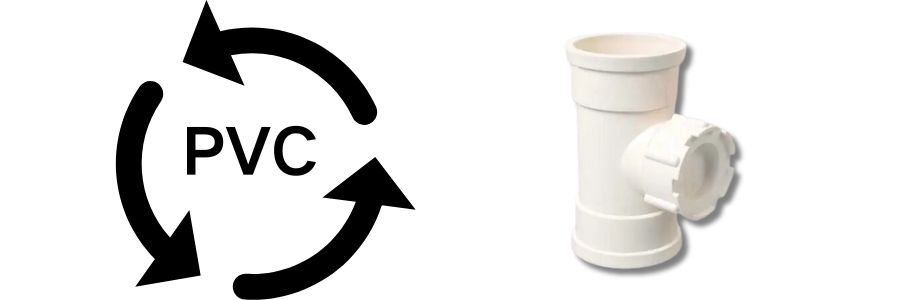

03—PVC (polyvinyl chloride)

Common uses of PVC: raincoats, plastic films, building materials, etc.Polyvinyl chloride is a white powder with an amorphous structure. It has a small degree of branching and a relative density of about 1.4. It has a glass transition temperature of 77~90°C and begins to decompose around 170°C. It has poor stability to light and heat. It is above 100°C or After long-term sunlight exposure, it will decompose to produce hydrogen chloride, which will further autocatalytically decompose, causing discoloration and rapid decline in physical and mechanical properties.This kind of plastic has good plasticity and is cheap. However, plastic products made of this material are prone to produce two toxic and harmful substances: one is single-molecule vinyl chloride that is not fully polymerized during the production process, and the other is harmful harmful substances in plasticizers. substance. These two substances are easy to precipitate when encountering high temperatures and grease. When toxic substances enter the human body with food, they can easily cause cancer. Therefore, never let it get heated while using it.

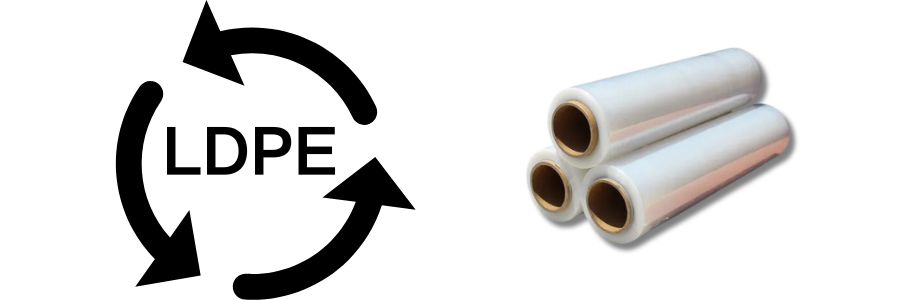

04—LDPE (low density polyethylene)

Common uses of low-density polyethylene: cling film, plastic film, etc. Low-density polyethylene, also known as high-pressure polyethylene, is a plastic material that uses ethylene as raw material and is fed into the reactor. Under the action of the initiator, the polymerization reaction is performed by high-pressure compression. The material coming out of the reactor is removed by the separator. After the unreacted ethylene is melted, extruded, granulated, dried and blended, it is suitable for various molding processes of thermoplastic molding and has good molding processability. The main use of low-density polyethylene is to make film products, but it is also used in injection molded products, medical equipment, pharmaceutical and food packaging materials, blow molding and hollow molding products, etc. The heat resistance of cling film made of this plastic is not strong. Qualified PE cling film will melt when the temperature exceeds 110°C, leaving some plastic preparations that cannot be decomposed by the human body. If food is wrapped in cling film and heated directly, At high temperatures, the fat in food can easily dissolve harmful substances in the plastic wrap, causing harm to human health. Therefore, it is best to remove the plastic wrap from the food before putting it in the microwave.

Common uses of low-density polyethylene: cling film, plastic film, etc. Low-density polyethylene, also known as high-pressure polyethylene, is a plastic material that uses ethylene as raw material and is fed into the reactor. Under the action of the initiator, the polymerization reaction is performed by high-pressure compression. The material coming out of the reactor is removed by the separator. After the unreacted ethylene is melted, extruded, granulated, dried and blended, it is suitable for various molding processes of thermoplastic molding and has good molding processability. The main use of low-density polyethylene is to make film products, but it is also used in injection molded products, medical equipment, pharmaceutical and food packaging materials, blow molding and hollow molding products, etc. The heat resistance of cling film made of this plastic is not strong. Qualified PE cling film will melt when the temperature exceeds 110°C, leaving some plastic preparations that cannot be decomposed by the human body. If food is wrapped in cling film and heated directly, At high temperatures, the fat in food can easily dissolve harmful substances in the plastic wrap, causing harm to human health. Therefore, it is best to remove the plastic wrap from the food before putting it in the microwave.

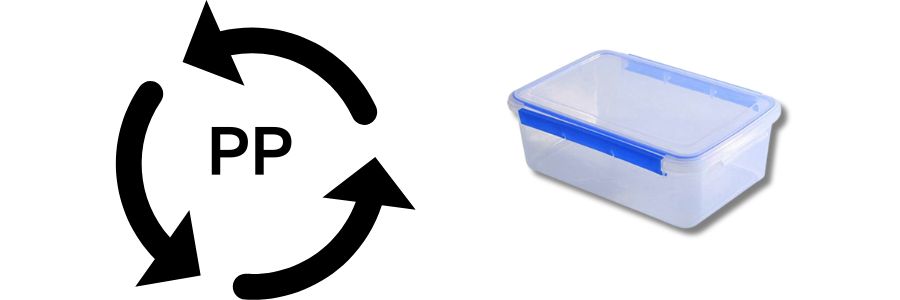

05—PP (polypropylene) Common uses of polypropylene: packaging bags, microwave lunch boxes, etc. Polypropylene is a semi-crystalline thermoplastic. It has high impact resistance, strong mechanical properties, and is resistant to various organic solvents and acid and alkali corrosion. It is widely used in industry and is one of the common polymer materials. Australian coins are also made from polypropylene. Microwave lunch boxes are made of this material, which is resistant to high temperatures of 130°C and has poor transparency. This is the only plastic box that can be directly placed in a microwave oven for heating, and can be reused after cleaning. Special attention should be paid to the fact that some microwave lunch boxes have a box body made of No. 05 PP, but the lid is made of No. 06 PS polystyrene. PS has good transparency, but it is not resistant to high temperatures, so it cannot be integrated with the box body. and put it in the microwave. The appearance of No. 06 PS polystyrene is easily distinguished from No. 05 PP. Therefore, for safety reasons, remove the lid before placing the container in the microwave.

Common uses of polypropylene: packaging bags, microwave lunch boxes, etc. Polypropylene is a semi-crystalline thermoplastic. It has high impact resistance, strong mechanical properties, and is resistant to various organic solvents and acid and alkali corrosion. It is widely used in industry and is one of the common polymer materials. Australian coins are also made from polypropylene. Microwave lunch boxes are made of this material, which is resistant to high temperatures of 130°C and has poor transparency. This is the only plastic box that can be directly placed in a microwave oven for heating, and can be reused after cleaning. Special attention should be paid to the fact that some microwave lunch boxes have a box body made of No. 05 PP, but the lid is made of No. 06 PS polystyrene. PS has good transparency, but it is not resistant to high temperatures, so it cannot be integrated with the box body. and put it in the microwave. The appearance of No. 06 PS polystyrene is easily distinguished from No. 05 PP. Therefore, for safety reasons, remove the lid before placing the container in the microwave.

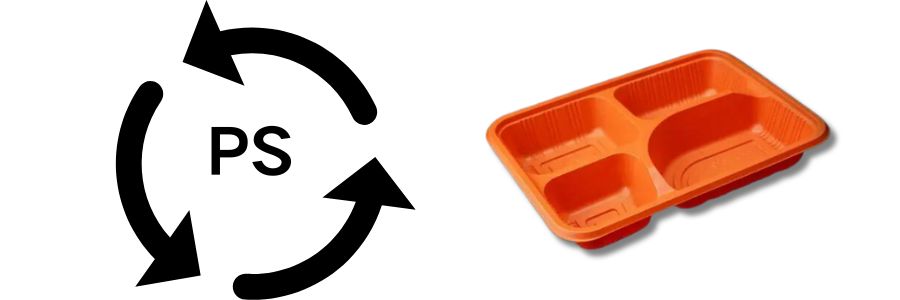

06—PS (polystyrene)

Common uses of polystyrene: bowls of instant noodle boxes, fast food boxes, etc. Polystyrene is a product obtained by the addition polymerization reaction of styrene monomer. It was first obtained from a volatile oil in natural resin balsam. Polystyrene has good corrosion resistance to acids, alkalis, salts, mineral oils, organic acids, lower alcohols, etc., but it softens or dissolves in organic solvents such as acetone, esters, aromatic hydrocarbons, etc. It has good insulation, transparency, high refractive index, water resistance and good colorability, and can be made into various colorful plastic products. It has very good fluidity when melted, is easy to process, and can be molded and extruded. Polystyrene can be used as a material to make bowl-type instant noodle boxes and foam fast food boxes. It is heat-resistant and cold-resistant, but cannot be placed in a microwave oven to avoid the release of chemicals due to excessive temperature. And it cannot be used to hold strong acids such as orange juice and strong alkaline substances, because it will decompose polystyrene that is not good for the human body.

Common uses of polystyrene: bowls of instant noodle boxes, fast food boxes, etc. Polystyrene is a product obtained by the addition polymerization reaction of styrene monomer. It was first obtained from a volatile oil in natural resin balsam. Polystyrene has good corrosion resistance to acids, alkalis, salts, mineral oils, organic acids, lower alcohols, etc., but it softens or dissolves in organic solvents such as acetone, esters, aromatic hydrocarbons, etc. It has good insulation, transparency, high refractive index, water resistance and good colorability, and can be made into various colorful plastic products. It has very good fluidity when melted, is easy to process, and can be molded and extruded. Polystyrene can be used as a material to make bowl-type instant noodle boxes and foam fast food boxes. It is heat-resistant and cold-resistant, but cannot be placed in a microwave oven to avoid the release of chemicals due to excessive temperature. And it cannot be used to hold strong acids such as orange juice and strong alkaline substances, because it will decompose polystyrene that is not good for the human body.

07—PC and other categories

Common uses of PCs and other types of PCs: kettles, space cups, baby bottles, etc. It is a material that is widely used, especially in the manufacture of baby bottles, space cups, etc. It has been controversial because it contains bisphenol-8. Experts point out that theoretically, as long as bisphenol is 100% converted into a plastic structure during the production process, it means that no bisphenol is incorporated into the product, let alone released. However, if a small amount of bisphenol is not frozen into a plastic structure, it may be released and enter food or drinks. Therefore, when using this plastic container, you must strictly follow the instructions for containing food, store and sterilize it in the correct way, and avoid repeated use of aged or damaged products. The higher the temperature, the more bisphenols are released and the faster they are released. Therefore, water bottles should not be used to hold hot water. If your kettle is numbered, the following methods can reduce the risk: Do not heat it when using it, and do not expose it to direct sunlight. No need to use a dishwasher or dishdryer to clean the kettle. Months before first use, wash with baking soda and warm water, and dry at room temperature. If the container has any scratches or damage, it is recommended to stop using it, because if there are tiny pits on the surface of plastic products, bacteria can easily hide. Avoid repeated use of aged plastic utensils.

Common uses of PCs and other types of PCs: kettles, space cups, baby bottles, etc. It is a material that is widely used, especially in the manufacture of baby bottles, space cups, etc. It has been controversial because it contains bisphenol-8. Experts point out that theoretically, as long as bisphenol is 100% converted into a plastic structure during the production process, it means that no bisphenol is incorporated into the product, let alone released. However, if a small amount of bisphenol is not frozen into a plastic structure, it may be released and enter food or drinks. Therefore, when using this plastic container, you must strictly follow the instructions for containing food, store and sterilize it in the correct way, and avoid repeated use of aged or damaged products. The higher the temperature, the more bisphenols are released and the faster they are released. Therefore, water bottles should not be used to hold hot water. If your kettle is numbered, the following methods can reduce the risk: Do not heat it when using it, and do not expose it to direct sunlight. No need to use a dishwasher or dishdryer to clean the kettle. Months before first use, wash with baking soda and warm water, and dry at room temperature. If the container has any scratches or damage, it is recommended to stop using it, because if there are tiny pits on the surface of plastic products, bacteria can easily hide. Avoid repeated use of aged plastic utensils.

1

Custom Plastic

We serve more than 200 customers, providing them with various plastic products

2

One-stop service

Professional engineering team and customer service team will connect with you and customize products according to drawings

3

Efficient delivery

We have 120+ employees, 40+ machines, 11,000+ square meters of space, and work 3 shifts 24 hours