Injection mold precautions and safety protection

The importance of injection molds is self-evident. The quality of the mold can directly determine whether the product meets the requirements and standards. In addition to the workmanship of the mold, the protection of the mold is also very important. If the workmanship causes defects in the mold, the proportion can be If it reaches 50%, then in the production injection molding process, the damage and defects caused by the use of the mold must account for more than 85%, which is indeed a bit high.

In such a high proportion, the first thing we think of is the protection of the mold. During our work and practice, we summarized,

We have summarized six points for the precautions for molds

First: Prevent mold collision

The collision of the mold will deform the mold, especially the collision with force, which will cause a deep pit in the mold product. In this way, the injection molded products produced will not meet the quality requirements. During production work, if the ejector pin is found to be broken, or the ejector pin is The collision caused by the inability to return to the original position will cause a small deformation of the mold, which will affect the injection molded products.

Second: Prevent the mold from rusting

When the mold is in the air for a long time, it will oxidize, causing the water vapor in the air to stick to the mold. Therefore, we often need to keep the mold dry. During the production process, if some mold leaks occur, the water vapor in the air will be wetted by rain. It may be exposed to rain or may cause rust reaction caused by contact with human hands. This needs to be avoided before use.

Third: missing parts

Sometimes the mold will add a number of parts to make the mold achieve a certain function, but sometimes a technician will install less parts because of your carelessness. Such long-term operation will cause the mold to become loose. Once loose, it will There is friction and impact. If there is friction and impact, you will reach the first point. The impact will cause slight deformation of the mold.

Fourth: Prevent the occurrence of burrs

Burrs are steel burrs. If they exist in the mold, if you want to make good products, they may have small holes. Burrs are mainly formed by cloth wiping, knife contact, nozzle pliers contact, and material punching, etc.

Fifth: Prevent mold crushing

This is mainly during the delivery process. Do not press enlarged steel or similar items on the mold. Another situation where the mold may be crushed is that after the injection molding is completed, some plastic remains in the mold. At this time, Talk about locking the mold, which will also cause the mold to be crushed.

Sixth: Prevent the mold from being under-pressured

The mold is pressed, and there is another type called under-pressure, which is to put pressure on the mold under pressure protection. This pressure is exactly the opposite of the front pressure, but the effect is the same and will cause certain damage to the mold.

Damage to the mold during the actual production process

In actual work and production, the main damage to the mold caused by collision occupies about 90%, and the probability that the inner ejector pin does not return is already over 80%, so how to make the mold return normally without collision , the phenomenon that causes the mold to become unusable will be tested to ensure that the expensive mold is not subject to collision.

1: Make sure the thimble is smooth enough

The ejector pin is smooth enough, and some lubricating oil will be applied on the ejector pin to ensure the normal return of the mold.

2: Monitor the mold

Our Yufeng Plastic Products Factory will adopt the reset point monitoring method. When the mold returns to its normal position, our start mechanism will not be triggered and the equipment will operate normally. When the mold does not return to the position we require, the trigger mechanism will take effect and the equipment will Stop the operation. At this time, the damage to the mold caused by not resetting can be greatly reduced.

For mold damage, we will take some precautions in advance

1: Add lubricant regularly

This is for the first point, it is more convenient for mold return

2:Remove rust regularly

Regarding the second point in this article, we often need to inspect the appearance, PL surface, core, and mold cavity, etc. We need to remove rust in these places to prevent oxidation of the mold.

3: Check parts

Every time we install the mold, we need to specifically check whether the parts have been installed according to regular procedures and whether there are no missing parts. During use, if parts are damaged, they also need to be replaced, such as tie rods or bolts.

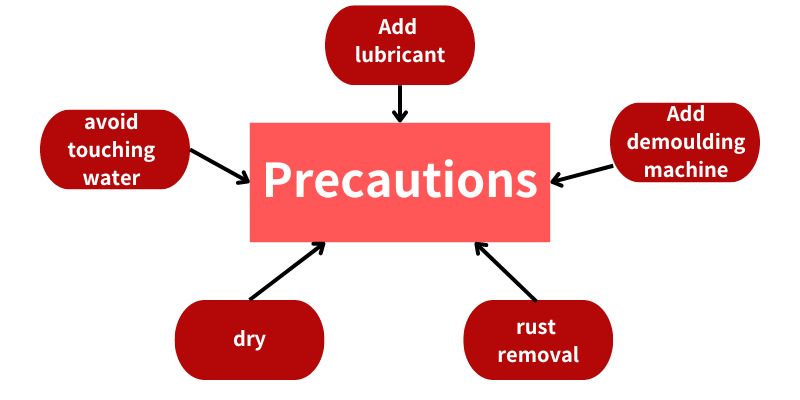

In daily work, the things we need to pay attention to are:

1: After the injection molding is completed, when disassembling the mold, be careful to avoid touching or allowing water to come into contact with the mold.

2: The mold must be derusted regularly.

3: The mold needs to be dried regularly.

4: The mold needs to be sprayed with reagents to prevent oxidation and buttered to make it more lubricated.

5: Spray some demoulding machine regularly on the fixed mold for demoulding.