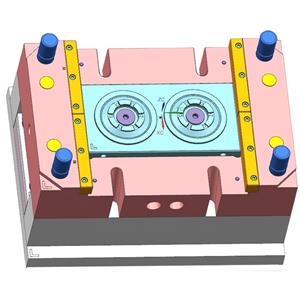

plastic injection mold

-

Bottle Cap

1. We use imported food-grade 100% new PE material to make our lids. 2. Internally lined with non-toxic PE foam "O" ring. 3. Customer-designed sealing label stickers are available. 4. Weight range from 8.38g to 12.2g for your choice. 5.Customized design: accepted 6.Service: OEM or ODM 7. Sample: available 8. Sample cost: buyer needs to provide express fee 9. Sample delivery time: within 15 days 10. Payment method: T/T 30% in advance, the balance is paid before shipment 11. Production time: 15-20 days 12. Delivery port: Xiamen

injection mold manufacturing plastic injection molding injection mould maker plastic injection partsEmail Details -

Bathroom Parts Plastic Injection Toilet Seat Cover Mold

1. One-stop Service: Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services; 2. Rich Experience: more than 15years experience for plastic injection mould and plastic injection and developing capability; 3. Advance Equipment: Imported sophisticated production and testing equipment with high stability. 4. Fast Quote: Based on 2D or 3D drawing, your sample, even your idea; 5. Tooling Maker: Injection mold, stamping die & die casting as well; 6. After Service:For your smoothly running machine or product use.

Bathroom Parts Mold Plastic Injection Toilet Seat Cover Mold Bathroom Parts Plastic Injection Mold Bathroom Parts Injection MoldEmail Details -

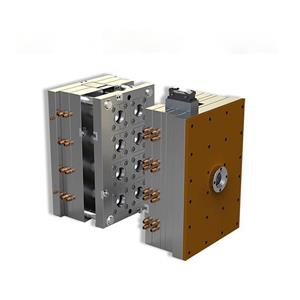

Precision Custom Plastic Injection Mould

1). Quickly response and complete understanding 2). The most competitive and reasonalbe price 3). Short delivery time and prompt delivery 4). Well and High Quality Control 5). Customer's Designs and Logos are welcome 6). Enough and advance machines and equipments.

Precision Custom Mold Precision Plastic Injection Mold Precision Custom Plastic Mold Precision Custom Plastic Injection MoldEmail Details -

Multi Or Single Cavity Plastic Parts Injection Molding

We continually works on development and improvement for holding the management tenets of integrity, Quality first and Credit Tops. By far, We are in possession of one lot advanced equipment and one excellent team. Our Products have already been setup good relationship with many domestic and oversea clients, We serve for customers with advanced technology, good quality, reasonable price and considerate after sale service, Our products are famous and get good reputation in both domestic market and oversea market.

Email Details -

Plastic Injection Molding For Spare Parts

For Plastic Injection Mould: 1. High quality raw material to ensure the high quality of the plastic injection mould; 2. Fast delivery, if the sample plastic injection mould, we can finish in 10days; 3. More than 800 mould making experience; 4. Can offer plastic injection making and injection plastic parts, silk screen print and spray paint one stop service. For Plastic Injection Products: 1. Advance injection machine to ensure the quality; 2. Enough and many kinds of injection machines to ensure the quantity; 3. High productivity;

Email Details -

Medical Plastic Products Injection Mold

1. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 2. With more than 20 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers. 3. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 4. advance Equipment-imported sophisticated production and testing equipment with high stability.

Email Details -

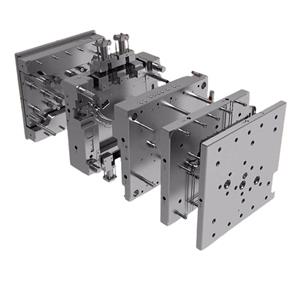

Custom Plastic Injection Mold For Industrial Parts

1. High quality and factory price for plastic injection mould service; 2. Plastic injection mould design and making service and plastic injection service for over 30 countries; Provide high-volume injection molding solutions; 3. One-stop service from plastic injection mould making to plastic injection and assembly;

Custom Plastic Injection Mold Injection Mold for Industrial Parts Plastic Injection Mold for Industrial Parts Custom Mold for IndustrialEmail Details -

Plastic Injection Molding Mould For Plastic Parts

1. We can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. 2. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 3. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Plastic Injection Molding Mould Mould for Plastic Parts Plastic Molding Mould Injection Mould for Plastic PartsEmail Details -

Fitness Equipment Spare Parts Plastic Injection Mold

1. Start from part design analysis; 2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making; 3. If product is complex, moldflow report will be present as well; 4. In house mold making shop ensure you mold quality under well control; 5. Normally it takes 20-40 days to make mold, precise time depends on part design; 6. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service; 7. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment; 8. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Spare Parts Plastic Mold Spare Parts Injection Mold Spare Parts Plastic Injection Mold Fitness Equipment Spare Parts MoldEmail Details