How to Choose the Quantity of Cavity for Your Plastic Injection Mold?

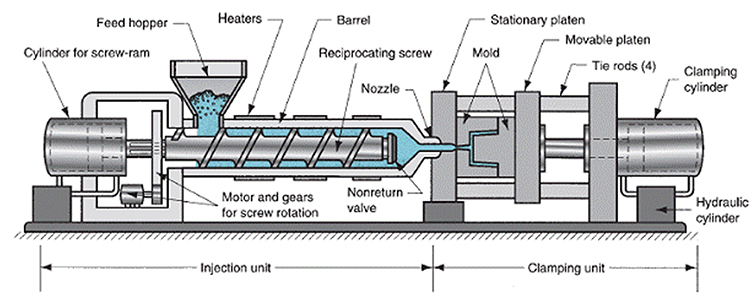

Plastic injection Mold was widely used in all kinds of the industry in our daily life, such as households, fitness, electronics and so on. Its importance should be self-evident and a better plastic injection mold is work effectively and efficiently. But how to make a better plastic injection mold? There are many factors and we would like talking about how to choose the quantity of cavity for your plastic injection mold here.

Three are three points that we must to think about: Size of the product, the demand of the products per year and the tons of the plastic injection machine.

If your product size is small, such as the plastic test tube for the medical, there are about 20-50 cavities and the mold will not very large. And it is only a little requirement to the plastic injection machine and it is easy to find the plastic injection machine. If the cavity is less, it will waste the cost of the produce. For example, use 160T plastic injection machine, its cost is US$ 1 per time, it is US$0.1 for a 10 cavities plastic mold and US$0.05 for a 20 cavities plastic mold.

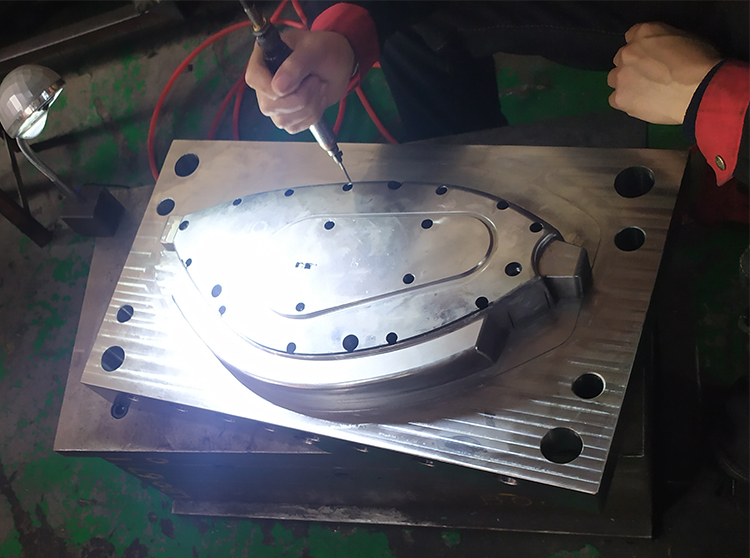

Different products, different size, some are big and some are small. For example, a plastic cover for exercise bike, we must think about its demand per year. If your demand is a million or more, you may choose a two or more cavities mold; but if your demand is one hundred thousand or less, you had better choose a cavity mold. As the bigger machine, its cost is also higher per time.

For the tons of the plastic injection machine, we still talking about the plastic cover of exercise bike as example. If a one cavity plastic injection mold, 500T plastic injection machine can work. But for a two cavities plastic injection mold, it is much bigger that the 500T plastic injection machine can not work for it and you had to a bigger machine, such 600T plastic injection machine and your factory may be do not have that machine and also its cost must be considered.

Then some of the plastic products is too big to make a one cavity mold. One is it is hard to find the big plastic injection machine, and the other is it is hard to produce that use a big plastic injection machine. Such as, plastic chair, big plastic bucket and so on, What's more, the produce cost is much more expensive for the big plastic injection machine.