Precision Injection Molding Plastic Products

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

We have a professional engineers design team with more than people and can use CAD, Pro-E, UG, Solidworks etc. to ensure all kinds of design.Before the project started:

1. If you have 3D STEP/IGES/X_T drawing or 2D drawing, please send it to us before quotation, then we will do DFM and mould design for you.

2. If you only have samples please provide us the samples, we can design 3D drawing for you and quotation.

We have enough and advance equipment and machines, such as high CNC and other equipment for plastic mold making, 60 to 950T plastic injection machines for the plastic mold, assembly line for spray print and other machine for us to provide the one-stop service.

Precision Injection Molding Plastic Products

Plastic Injection Products Specification:

Product name | Precision Injection Molding Plastic Products |

Main services | 3D design, Prototypes, Mold design, Mold making, Mold tesing, Low volume/ High volume plastic injection production |

Design Software | UG,Pro E Solidwork,AutoCAD,Moldflow |

Core&Cavity Material | P20,H718,S136,SKD61,2738,DC53,H13.... |

Hardness of the steel | 20~60 HRC |

Cooling system | In core baffle and in cavity plate chain drilling type cooling |

Mold strandard parts | DME, HASCO, etc. |

Plastic material | ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc. |

Surface treatment | Polish, texture, sand blasting, chrome plating |

Mould life | 300,000-1,000,000 shots |

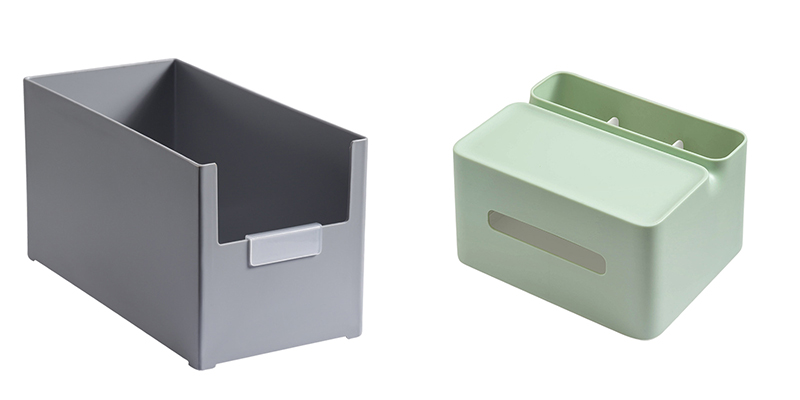

Plastic Injection Products Picture:

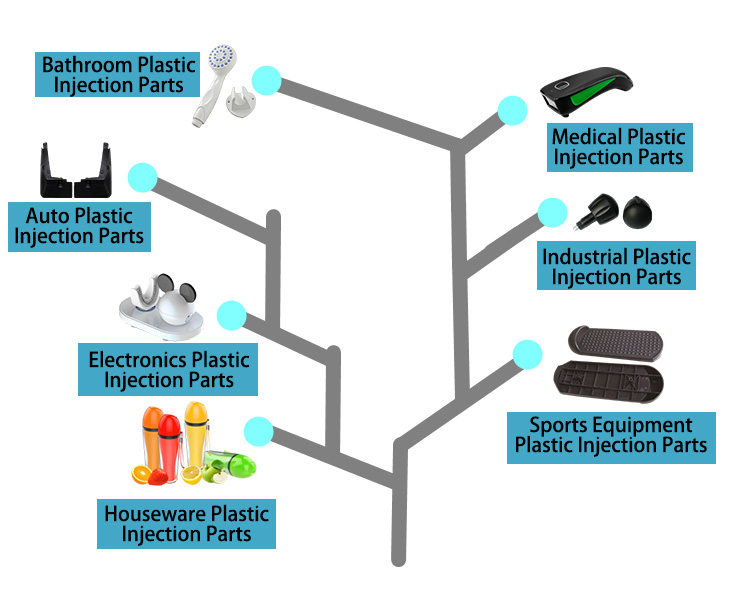

Plastic Injection Products Feature and Application:

1. Shape can be from simple to complex, the size can be from large to small and the product size is accurate;

2. It is used in the forming and processing fields of mass production and products with complex shapes.

We design and manufacture plastic injection molds home applications, medical products, Household commodities, consumer electronics, mobile phone parts and accessories, auto parts, and many other kinds of molds in different fields.

3. Efficiency production and automotive operation;

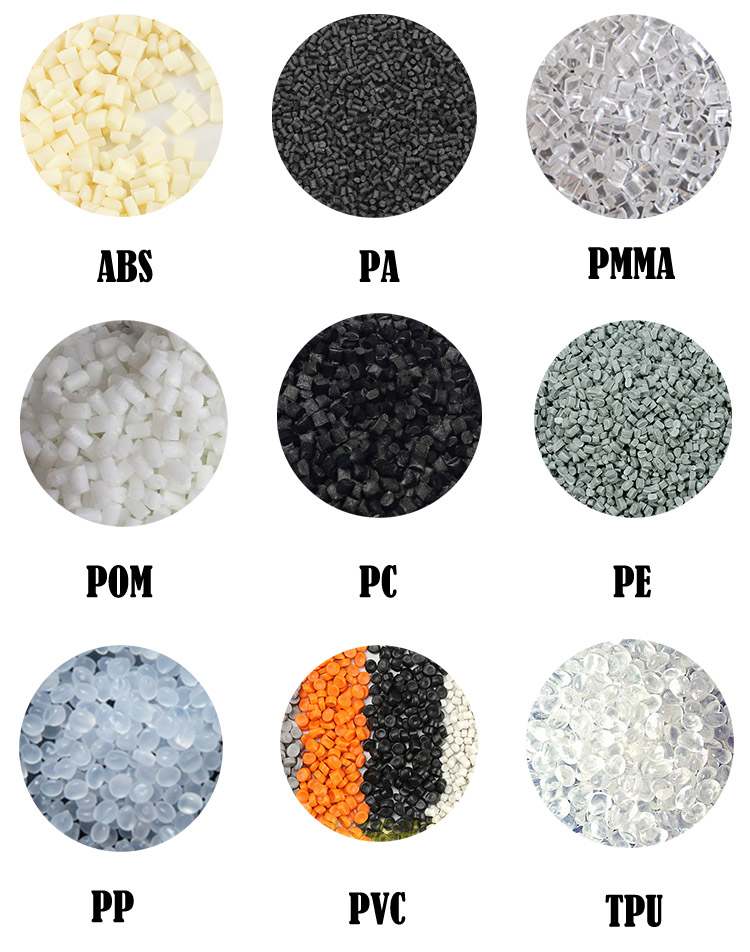

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Our Plastic Parts Case Show:

Payment and Shipping:

We accept many kinds of the payment, the details as the following:

1. For the samples, we can accept PayPal, West Union and Bank Transfer as the payment, and will ship the samples by air express, such as the DHL, UPS and FEDEX.

2. For the bulk order, we can suggest the bank transfer as the payment method with the 30% deposit, we will ship out the goods according to the choice from the customers for shipping.

3. We can ensure the shipping is fast and efficient.

FAQ About Molded Products:

Q1: How many injection plastic mouldings machines do you have?

A1: We have more than 50 sets of plastic Injection Mouldings machines.

Q2: what is the minimum & maximum unit weight and size your machines can produce?

A2: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q3: What kind of plastic materials you usually use?

A3: We are specialized in producing plastic products with the following materials: PP, ABS, PC, POM, PA, HDPE, HIPE, PS, AS, PBT, PET, PMMA, PVC and so on.